what is a concrete block making machine

Feb 28, 2025

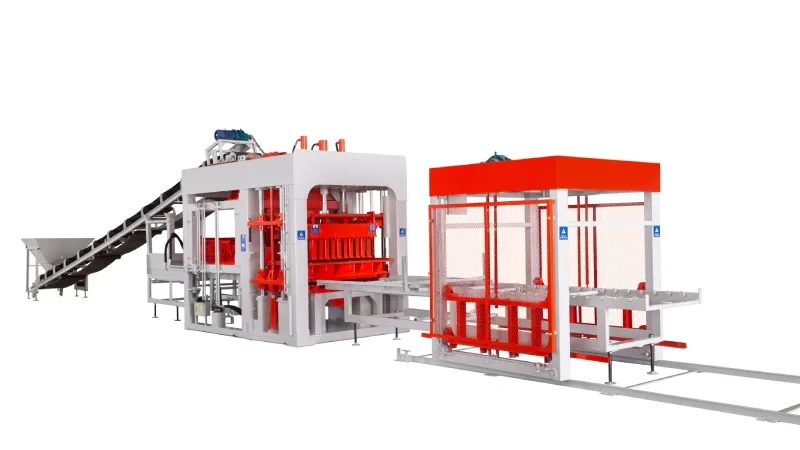

A concrete block making machine is a specialized device used to manufacture concrete blocks, bricks, pavers, and other construction materials by compacting a mixture of cement, aggregates (sand, gravel), and water into molds. These machines are essential in construction for producing uniform, high-quality blocks efficiently. Here’s a detailed breakdown:

How It Works:

- Mixing: Raw materials are blended (either manually or via an integrated mixer) to form a semi-dry concrete mix.

- Molding: The mix is fed into molds, where hydraulic or mechanical pressure compresses it. Vibration is often applied to remove air pockets, ensuring density and strength.

- Demolding: The freshly formed blocks are ejected from the molds.

- Curing: Blocks are left to dry and harden, either naturally (air-cured) or in controlled environments (steam-cured chambers for faster results).

Key Components:

- Hopper: Holds raw materials before mixing.

- Mixer: Combines cement, aggregates, and water (optional in some models).

- Mold System: Interchangeable molds for creating different block shapes (hollow, solid, paving, interlocking).

- Compaction System: Uses vibration, hydraulic pressure, or mechanical force to densify the mix.

- Control Panel: Manages automation levels (manual, semi-auto, or fully automatic).

- Conveyor System: Transports blocks for stacking or curing (in advanced models).

Types of block making Machines:

- Manual/Semi-Automatic:

- Operated via levers or pedals; low output (100–500 blocks/hour).

- Affordable, suitable for small businesses or rural areas.

- Fully Automatic:

- High-capacity (1,000–5,000+ blocks/hour) with minimal human intervention.

- Integrated mixing, molding, and stacking systems; ideal for large-scale production.

- Mobile Machines:

- Portable units for on-site block production, reducing transport costs.

- Stationary Plants:

- Fixed installations for continuous, high-volume output.

Applications:

- Building construction (walls, foundations).

- Pavement and landscaping (pavers, curbstones).

- Specialty blocks (insulated, decorative, interlocking for erosion control).

Advantages:

- Efficiency: Faster production than manual methods.

- Consistency: Uniform block size and strength.

- Cost-Effective: Reduces labor and material waste.

- Versatility: Adaptable to different block designs via mold changes.

Considerations:

- Initial Investment: Higher cost for automated systems.

- Power Source: Electric, diesel, or hybrid options.

- Maintenance: Regular cleaning of molds, checking hydraulic systems.

- Local Standards: Machines must comply with regional construction codes (e.g., ASTM, IS, EN).

Environmental Impact:

- Can incorporate recycled materials (crushed concrete, fly ash).

- Optimizes resource use, reducing waste.