What Is The Function Of Pvc Board?

Out 9, 2024

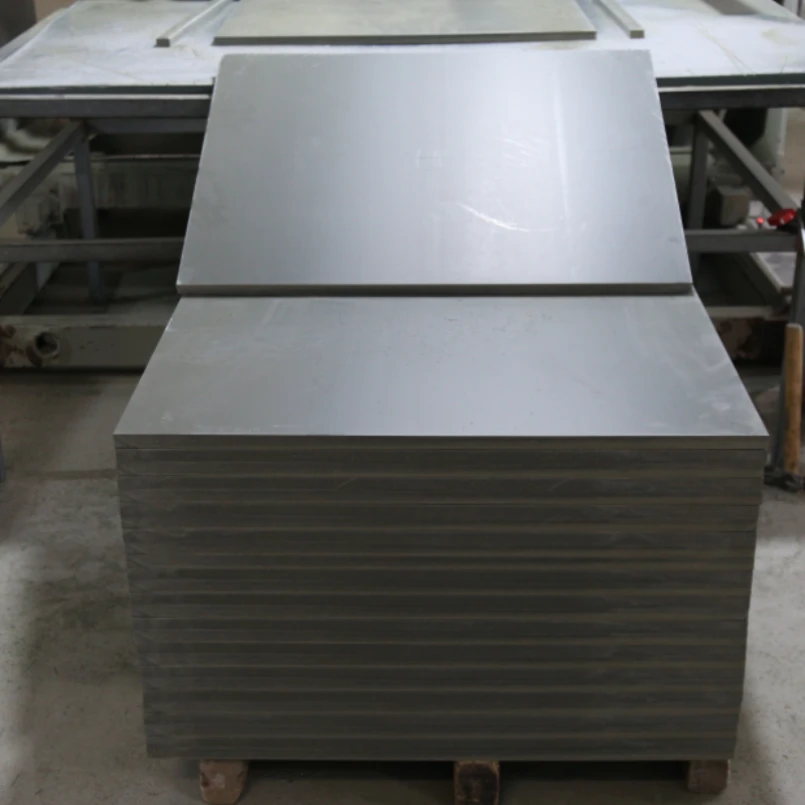

PVC boards have become essential materials across various industries due to their versatility, durability, and low maintenance requirements. As a leading PVC board manufacturer, KBL Machinery is dedicated to producing high-quality PVC boards that serve numerous functions. Here, we delve into the key applications and benefits of PVC boards, along with their role in the manufacturing of PVC pallets.

Key Functions of PVC Boards

Construction and Building Materials:

PVC boards are commonly used in construction for walls, ceilings, and partitions. They provide excellent insulation and are resistant to moisture, making them ideal for areas prone to humidity.

Furniture Manufacturing:

The lightweight nature and aesthetic appeal of PVC boards make them popular in furniture design. They can be easily cut and shaped, allowing for creative and innovative furniture solutions.

Signage and Advertising:

PVC boards are widely used for outdoor signage due to their weather-resistant properties. They retain color and finish, making them suitable for advertisements that require durability and visibility.

Packaging Solutions:

PVC pallets, made from PVC boards, are increasingly used in packaging and logistics. They offer a lightweight, sturdy alternative to traditional wooden pallets, enhancing efficiency in storage and transportation.

Automotive Applications:

In the automotive industry, PVC boards are utilized for interior paneling and trim. Their resistance to chemicals and ease of cleaning make them an attractive option for automotive manufacturers.

Electrical Insulation:

PVC boards are excellent insulators, making them suitable for various electrical applications. They help protect against electrical shocks and provide a safe working environment.

Benefits of Using PVC Boards

- Durability: PVC boards are resistant to rot, corrosion, and pests, ensuring a long lifespan.

- Low Maintenance: Unlike traditional wood, PVC boards require minimal upkeep, saving time and costs.

- Eco-Friendly Options: Many PVC board manufacturers, including KBL Machinery, offer recyclable products, contributing to sustainability.

- Cost-Effectiveness: With their longevity and low maintenance, PVC boards often prove to be more economical over time.

How To Maintain The Pvc Board?

Care for the panels in PVC to make them last longer, serving properly. These panels are extremely durable and also require less maintenance, but the usual care would still put them in excellent condition.

First of all, regular cleaning is the most important thing. A soft cloth or sponge dampened with a mild detergent in water does a good job of removing dirt and grime. Harsh cleaners and scouring pads should not be used because they scratch the surface and dull the aesthetic look of the board.

Beyond regular cleaning, it’s also worth checking your boards periodically for any signs of damage. A search for minor cracks or discoloration will allow you to fix the problem before it could get worse. Whenever these damages were found, they could immediately be repaired to avoid further deterioration. Applying a UV-resistant coating can help lock in plank color and prevent fading from extreme weather conditions.

Other maintenance involves proper installation. Installation performed with regard to securing the boards minimizes motion and finally avoids stress, which can cause warping or misalignment. Moreover, if not in use, keeping PVC boards out of direct sunlight can preserve their integrity and avoid unnecessary wear and tear.

In conclusion, PVC boards play a vital role in multiple sectors, from construction to packaging. As a trusted PVC board manufacturer, KBL Machinery is committed to delivering high-quality products that meet the diverse needs of our clients. With their numerous functions and advantages, PVC boards are undoubtedly a valuable addition to modern manufacturing and construction practices.