Block Moulds: Essential for Sustainable and Efficient Construction

Block moulds are increasingly essential in the transition toward sustainable construction practices. Machines that incorporate advanced block moulds are designed to optimize energy usage and maximize output, allowing manufacturers to lower operational costs while reducing their environmental footprint. Utilizing automated controls, minimal water usage, and optimized heating processes, these machines produce high-quality blocks with significantly less energy. Such efficiency aligns with global sustainability goals and helps businesses meet regulatory standards. KBL Machinery, a trusted construction equipment supplier, offers advanced machines with moldes para blocos that not only promote environmental conservation but also enhance production efficiency, giving companies a competitive edge in a demanding market.

Moreover, eco-friendly block moulds accommodate sustainable materials, such as recycled or locally sourced inputs, further lowering the environmental impact of production. These moulds enable the creation of blocks that are free from pollutants, meeting the demand for green building products. As construction projects increasingly emphasize environmental consciousness, Moldes para tijolos de estrada and other customized options help manufacturers align with these trends while building a positive reputation in the industry. By adopting sustainable practices through block moulds, companies position themselves as leaders in green construction.

The efficiency of block moulds extends beyond environmental benefits, offering significant business advantages as well. Lower energy consumption translates to reduced utility costs, while higher production rates and resource efficiency improve productivity. Additionally, eco-friendly technology can strengthen a company's brand image, attracting partners and customers who prioritize sustainability. In an era where responsible practices drive profitability, investing in block moulds with advanced features offers a clear path to long-term growth and leadership in construction.

Five Key Considerations for Choosing Block Moulds

- Production Capacity: Assess your current and projected production needs to ensure the block moulds you choose will support both immediate and future demand. Machines with adaptable production capacities will help you avoid bottlenecks as your business scales.

- Automation Level: Machines come in various automation levels, from manual to fully automatic. Selecting the right level for your operation depends on labor costs, production speed, and your goals for efficiency. While fully automated systems have higher upfront costs, they reduce labor costs and increase output.

- Eficiência energética: Energy-efficient block moulds reduce power consumption, benefiting both operational budgets and sustainability targets. Energy savings can offset the initial equipment cost, making efficiency-focused machines a worthwhile investment.

- Consistency and Quality: High-quality block moulds produce blocks with consistent size, strength, and durability. Ensuring precision and uniformity prevents costly rework and waste, directly impacting project success and customer satisfaction.

- After-Sales Support and Maintenance: Choosing a reliable construction equipment supplier like KBL Machinery ensures access to technical support, training, and spare parts, minimizing downtime and extending machine lifespan.

About KBL Machinery: A Leading Construction Equipment Supplier

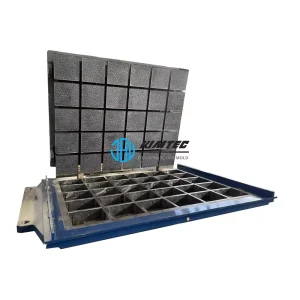

Máquinas KBL is a premier fornecedor de equipamento de construção known for its high-quality block moulds, Road Brick Moulds, and other advanced machinery. With years of expertise, KBL Machinery specializes in energy-efficient, eco-friendly equipment designed to meet the demands of modern construction. Each product combines high production capacity, durability, and precision. KBL Machinery’s emphasis on customer satisfaction extends to offering comprehensive after-sales support, training, and maintenance, ensuring reliable operations and long-term success for clients.

| Key Factor | Description |

|---|---|

| Production Capacity | Ensure the machine’s capacity aligns with both current and projected demand. |

| Automation Level | Choose the level of automation that suits your labor resources and production goals. |

| Eficiência energética | Look for energy-saving features to reduce power costs and support sustainability goals. |

| Consistency and Quality | High-quality moldes para blocos ensure uniform blocks, minimizing waste and enhancing structural reliability. |

| After-Sales Support | Partnering with a reputable fornecedor de equipamento de construção like Máquinas KBL guarantees access to spare parts and support. |