Block Maker Machines: A Revolution in Efficient Brick Production

The introduction of advanced block maker machines has transformed the brick manufacturing industry, offering unparalleled efficiency and precision. KBL Machinery is at the forefront of this transformation, providing cutting-edge block maker machines that automate the entire production process. From raw material preparation to the final shaping and curing of blocks, these machines significantly reduce manual intervention, ensuring consistent quality across every batch. By using block maker machines, manufacturers can streamline their production lines, boost productivity, and maintain the high standards required for modern construction projects.

KBL Machinery's máquinas de fabrico de tijolos are designed to handle various production needs, from small-scale projects to large industrial operations. With automation features that reduce human error, these machines ensure that each brick produced meets precise size, shape, and strength specifications. This level of precision not only enhances product quality but also improves the overall efficiency of the production process. By optimizing raw material usage and reducing waste, KBL’s block maker machines contribute to a more cost-effective and sustainable manufacturing approach.

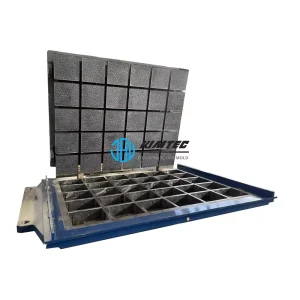

Furthermore, block maker machines from KBL are built to offer flexibility, allowing manufacturers to produce a wide range of block types, including hollow, solid, and interlocking blocks. This versatility enables companies to cater to diverse market demands, from residential to commercial construction projects. Whether you are producing standard blocks or customized bricks, KBL Machinery ensures that your production line is equipped to meet varying needs efficiently and consistently.

| Feature | Benefit |

|---|---|

| Full automation | Minimizes labor costs and maximizes production efficiency |

| Versatility in block types | Produces multiple block shapes and sizes for various applications |

| Precise material usage | Reduces waste and lowers production costs |

| Sustainable production options | Supports eco-friendly building practices and sustainability goals |

How KBL Machinery Block Making Machines Benefit Construction Projects

- Efficiency and Productivity

KBL Machinery's Máquinas de fazer blocos are designed to optimize the brick production process. With automation and real-time monitoring, these machines enhance productivity, enabling manufacturers to meet tight deadlines without compromising on product quality. This boost in efficiency translates into higher output and reduced lead times, allowing construction companies to keep pace with project demands. - Cost-Effective Solutions

By automating key aspects of the brick making process, KBL’s block maker machines help reduce labor costs and minimize waste. The machines are also engineered for energy efficiency, using less power while maintaining high output levels. These cost-saving benefits make KBL’s solutions ideal for businesses looking to improve their bottom line. - Durability and Reliability

KBL Machinery designs its block maker machines for long-term use, with robust construction and durable components that can withstand the rigors of continuous operation. The machines require minimal maintenance, reducing downtime and ensuring consistent production. This reliability ensures that businesses can maintain uninterrupted operations, even in demanding environments. - Sustainability in Manufacturing

KBL’s block maker machines support sustainable manufacturing by optimizing the use of raw materials and reducing energy consumption. The ability to incorporate eco-friendly materials, such as recycled aggregates, allows manufacturers to align their production with green building practices. This commitment to sustainability benefits both the environment and the business’s reputation in the industry.

Maintenance Best Practices for Block Maker Machines

To extend the lifespan and ensure the optimal performance of block maker machines, KBL Machinery recommends the following best practices:

- Regular Inspection and Cleaning: Keep the machine free from dust, debris, and raw material buildup by performing regular cleanings. Daily inspections help identify wear and tear early, preventing more serious issues from developing.

- Lubrificação de peças móveis: Ensure all moving components, such as gears and bearings, are regularly lubricated to minimize friction and prevent heat buildup, which can cause damage over time.

- Monitor and Replace Worn Parts: Key components like molds, belts, and hydraulic systems should be regularly checked for wear and replaced as needed to avoid unexpected breakdowns and costly repairs.

- Calibration: Periodically recalibrate the machine to ensure precision in production. Over time, automated systems and sensors may drift, affecting the quality and consistency of bricks.

Why Choose KBL Machinery as Your Construction Equipment Supplier

KBL Machinery stands out as a leading fornecedor de equipamento de construção, providing high-quality, reliable, and efficient máquinas de fabrico de blocos for various construction projects. With years of experience and a commitment to innovation, KBL Machinery offers tailored solutions that cater to different production needs, ensuring that businesses can optimize their operations and enhance productivity. In addition to top-tier machines, KBL Machinery delivers exceptional after-sales support, including maintenance services and training, ensuring long-term success for its clients in the competitive construction market.