The Role of Concrete Pavement Moulds in Modern Construction

Concrete pavement moulds have become essential tools in modern construction, transforming how building materials are produced with improved efficiency and precision. KBL Machinery designs advanced concrete pavement moulds that streamline production processes, enabling construction companies to produce high-quality blocks and pavers in large quantities. By automating traditional labor-intensive tasks, KBL Machinery helps construction firms reduce labor costs, saving both time and money while ensuring that each block or paver meets the stringent standards required for modern infrastructure. As the demand for scalable solutions grows, KBL Machinery’s moulds provide the efficiency and scalability needed to meet the tight timelines of major construction projects.

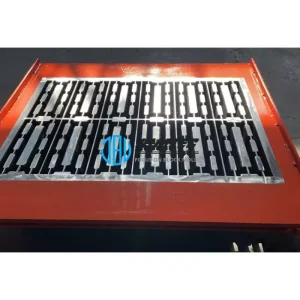

KBL Machinery's concrete pavement moulds not only enhance production efficiency but also guarantee consistent block size, strength, and durability. These moulds are compatible with a variety of materials, allowing companies to produce blocks suitable for multiple applications, from residential pathways to large industrial roads. The uniformity of blocks produced by KBL Machinery’s Moldes para blocos ensures greater structural integrity, minimizing the risk of construction defects and boosting the longevity of projects.

The eco-friendly features of KBL Machinery’s concrete pavement moulds help construction companies align with global sustainability goals. Designed with energy-efficient technologies and capable of using recycled materials, these moulds reduce environmental impact while lowering production costs. As the industry shifts toward sustainable building practices, KBL Machinery leads the way with solutions that not only increase productivity but also contribute to the future of green construction.

Key Benefits of Automated Block Moulds from KBL Machinery

- Aumento da eficiência da produção: Automated Block Moulds from KBL Machinery bring exceptional efficiency to the entire production process, allowing construction companies to produce large volumes of blocks and bricks swiftly. This rapid production supports larger projects and enhances profitability through improved workflow.

- Qualidade consistente: Automation ensures each block is manufactured to precise standards, guaranteeing uniform size, strength, and durability. KBL Machinery’s Moldes para tijolos de estrada help maintain quality consistency, enhancing the structural reliability of buildings and reducing the risk of issues later on.

- Redução dos custos de mão de obra: Automation cuts down on manual labor, enabling businesses to reduce labor costs significantly. By streamlining production, KBL Machinery enables companies to operate more cost-effectively, reallocating resources to other operational needs.

- Eficiência energética: KBL Machinery designs its machines to conserve energy while maintaining high output. This feature helps companies lower their electricity expenses and aligns with sustainable building practices. Energy-efficient concrete pavement moulds support a reduced carbon footprint, making them an ideal choice for environmentally conscious firms.

- Customization Flexibility: Modern construction often requires varied brick and block designs, and KBL Machinery’s automated moulds can easily switch between different types, sizes, and shapes. This flexibility eliminates the need for multiple machines, enhancing versatility and adaptability to diverse project requirements.

Why Choose KBL Machinery as Your Construction Equipment Supplier?

As a leading fornecedor de equipamento de construção, KBL Machinery provides innovative, reliable, and high-performance solutions for block and brick production. With years of experience, KBL Machinery understands the unique demands of construction businesses and offers machinery designed for precision, energy efficiency, and durability. Our commitment to customer satisfaction includes exceptional support and advanced technology, making us the preferred partner for companies seeking to enhance productivity and achieve lasting success in the industry.

| Key Feature | Description |

|---|---|

| Aumento da eficiência da produção | Rapid production supports larger projects with enhanced profitability. |

| Qualidade consistente | Ensures uniform size, strength, and durability in each block. |

| Redução dos custos de mão de obra | Lowers costs by minimizing manual labor through automation. |

| Eficiência energética | Reduces power consumption, supporting sustainable practices. |

| Customization Flexibility | Easily adjusts to different block designs and sizes for diverse needs. |

Selecting KBL Machinery’s concrete pavement moulds, Block Moulds, and Road Brick Moulds guarantees access to innovative solutions from a trusted construction equipment supplier, committed to delivering productivity, efficiency, and sustainability in the modern construction landscape.