Como as máquinas de fabrico de tijolos estão a moldar o futuro da construção

28 de dezembro de 2024

Introduction: The Role of Bricks in Modern Construction

Bricks have long been a staple in construction, offering durability, strength, and versatility. In modern construction, bricks not only provide structural integrity but also contribute to energy efficiency and cost savings. With rising demand for high-quality bricks, the industry is increasingly turning to bricks manufacturing machines to meet production needs. These machines automate the brick production process, significantly improving efficiency, consistency, and cost-effectiveness. This shift is transforming the brick-making landscape, making it easier to meet the needs of large-scale projects and improve sustainability.

The Evolution of Brick Manufacturing Machines

From manual labor to fully automated systems, the evolution of máquinas de fabrico de tijolos has dramatically changed the way bricks are produced. Traditional brick manufacturing involved labor-intensive methods, with workers manually mixing, molding, and curing the bricks. However, as the demand for bricks has grown, manufacturers have adopted more advanced machinery.

Today’s bricks manufacturing machines are highly automated, integrating advanced technologies that streamline the entire production process. These machines are capable of producing large volumes of bricks with higher precision, reducing the need for manual labor and minimizing human error. As a result, production is faster, more consistent, and more cost-effective.

KBL Machinery has played a key role in this transformation, providing high-quality, innovative brick manufacturing equipment designed to meet the needs of modern construction.

Advantages of Modern Brick Manufacturing Machines

Increased Production Speed

One of the primary advantages of bricks manufacturing machines is their ability to significantly increase production speed. Automation allows for continuous production without the need for frequent breaks or manual intervention. This increased speed is crucial for meeting the demands of large-scale construction projects, where time is often a critical factor. With máquinas de fabrico de tijolos, manufacturers can produce more bricks in less time, ultimately reducing production costs and meeting tight deadlines.

Improved Consistency and Quality

Consistency and quality are essential in brick production, especially for construction projects that require precise specifications. Bricks manufacturing machines ensure that each brick is produced to exact specifications, offering uniform size, shape, and strength. The automated process reduces variability that often occurs in manual production, ensuring that every batch meets industry standards and customer expectations.

Cost-Effectiveness

By reducing the need for manual labor and increasing production efficiency, bricks manufacturing machines offer significant cost savings. Automation helps lower operational costs in several ways: it minimizes labor costs, reduces material waste, and improves energy efficiency. This cost-effectiveness makes these machines an attractive option for brick manufacturers looking to improve their bottom line while maintaining high-quality standards.

How Brick Maker Machines Are Revolutionizing Construction

Meeting the Demands of Large-Scale Projects

As construction projects grow in scale and complexity, the demand for reliable, high-quality bricks increases. Brick maker machines have become essential for meeting these needs. Automated machines can produce large quantities of bricks quickly, ensuring that there is always enough material on hand for large projects. Whether it’s residential, commercial, or infrastructure work, these machines provide the reliability needed to keep projects on schedule.

Enhancing Sustainability

Sustainability is a growing concern in the construction industry. Bricks manufacturing machines contribute to more sustainable production by reducing material waste and energy consumption. The precise molding and cutting capabilities of these machines ensure that raw materials are used efficiently, minimizing waste. Additionally, modern machines are designed to be energy-efficient, reducing the overall environmental impact of brick production.

Customizing Bricks for Different Needs

Another significant advantage of máquinas de fabrico de tijolos is their ability to produce bricks in various sizes and types to meet specific construction needs. From hollow bricks to solid blocks, these machines can be easily adjusted to create different products. This flexibility makes them ideal for diverse building projects, whether the requirement is for bricks with enhanced thermal insulation or aesthetic appeal.

KBL Machinery: Leading the Way in Brick Manufacturing Equipment

KBL Machinery’s Experience and Expertise

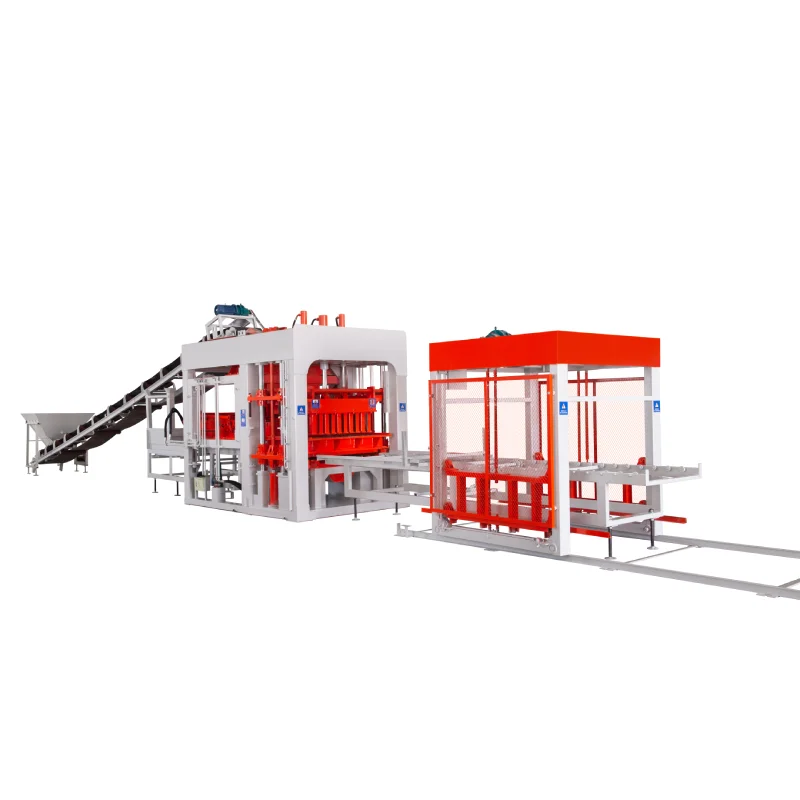

With over 30 years of experience in the brick manufacturing industry, KBL Machinery has established itself as a trusted provider of high-quality equipment. Our bricks manufacturing machines are built to offer durability, precision, and efficiency, helping our clients meet their production goals with ease. We specialize in a wide range of brick-making machines, including the popular QT series fully automatic concrete block machines, as well as static hydraulic press series with varying production capacities.

Product Range and Customization

At KBL Machinery, we offer a diverse range of machines tailored to different production needs. Whether you require machines for small-scale projects or large-scale production, we have the equipment to meet your requirements. Our machines are also customizable, allowing you to produce various types of bricks based on the specific needs of your project. The brick machine from China is an ideal choice for manufacturers looking to achieve high efficiency and consistency at competitive prices.

Global Reach

As a leading manufacturer, KBL Machinery has successfully exported its máquinas de fabrico de tijolos to over 50 countries worldwide. Our machines are trusted by clients in regions such as Southeast Asia, Europe, the Middle East, and Africa. Our global reach ensures that businesses around the world can benefit from the efficiency, durability, and cost-effectiveness that our machines offer.

Porquê escolher a KBL Machinery?

KBL Machinery is committed to providing high-quality products and exceptional customer service. We offer customized solutions designed to meet the unique needs of our clients, ensuring that every project is a success. With our proven track record and extensive expertise in the industry, we are the preferred choice for brick manufacturers looking to invest in reliable, high-performance equipment, including the brick machine from China.

The Future of Brick Manufacturing

As the construction industry continues to evolve, bricks manufacturing machines will play an even more significant role in shaping the future of the sector. With advancements in automation and technology, brick production will become faster, more efficient, and more sustainable. KBL Machinery is at the forefront of these innovations, continually pushing the boundaries of what is possible in brick manufacturing.