How an Automatic Interlocking Brick Machine Improves Construction Efficiency

Dez 23, 2024

The construction industry is undergoing significant changes, with automation becoming a driving force behind efficiency improvements. Key innovations such as the automatic fly ash bricks machine, automatic interlocking brick machinee fully automated brick making machine are transforming brick production. These machines provide higher output, improved consistency, and lower costs, ultimately boosting construction project timelines and profitability.

Increased Production Speed and Efficiency

An automatic fly ash bricks machine significantly boosts production speed by reducing cycle times. These machines can produce bricks in as little as 12 seconds, speeding up production processes and ensuring that large orders are completed more quickly. The ability to automate key production steps helps businesses meet tight deadlines without compromising on quality. This enhanced speed not only increases overall capacity but also reduces labor requirements, further improving operational efficiency.

Consistent Quality and Precision in Production

Quality control is essential in the brick production process. Manual methods often lead to inconsistencies, which can affect the structural integrity of the final product. With automatic interlocking brick machines, businesses ensure consistent brick quality. These machines offer precise control over key parameters such as size, weight, and strength, resulting in high-quality, uniform products. For construction projects that demand reliability, having a consistent product every time is crucial to maintaining the structural integrity of buildings and infrastructure.

Significant Cost Reductions and Labor Savings

Labor costs account for a large portion of expenses in traditional brick-making processes. By using fully automated brick making machines, businesses can reduce these costs considerably. These machines automate most tasks, requiring minimal human involvement, which leads to savings on labor. Moreover, automation ensures that material usage is optimized, reducing waste and further lowering production costs. This cost-saving aspect is vital for businesses aiming to stay competitive in the fast-paced construction industry.

Eco-Friendly and Sustainable Production

Sustainability is a major concern in modern construction practices. The automatic fly ash bricks machine offers an environmentally friendly alternative by using fly ash as a primary material. Fly ash, a byproduct of coal combustion, is a waste product that can be repurposed into high-quality bricks. This helps reduce reliance on traditional clay bricks, which require more energy and raw materials. Additionally, automation reduces energy consumption during the production process, making these machines a greener choice for large-scale production.

Customization to Meet Specific Production Needs

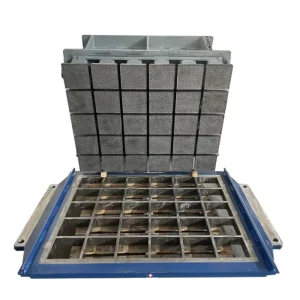

One of the major advantages of an automatic interlocking brick machine is its ability to be customized. These machines can be tailored to produce different types of bricks, such as interlocking bricks, which offer enhanced durability and easier installation. Customizing molds, pallets, and machine settings ensures that businesses can meet the specific needs of each project. Whether producing bricks for residential, commercial, or industrial applications, the flexibility of automated brick-making machines makes them suitable for a wide range of construction needs.

Higher Output and Automation

A key benefit of fully automated brick making machines is their high level of automation, which allows for faster production cycles. With fully automated systems, every stage of production, from mixing and forming to curing and stacking, is managed by the machine. This results in faster output, allowing companies to increase production without compromising quality. The ability to produce large volumes of bricks in less time makes these machines particularly beneficial for large-scale construction projects.

Reduced Downtime and Improved Operational Efficiency

With automation comes the benefit of reduced downtime. Automatic interlocking brick machines are designed to minimize interruptions during production, thanks to features such as automatic maintenance alerts and easy troubleshooting. This allows for continuous production with fewer delays, increasing overall efficiency. In addition, with fewer workers needed to operate the machines, businesses can redirect their human resources to more specialized tasks, further enhancing labor efficiency.

Why Choose an Automated Brick Making Machine?

Investir em fully automated brick making machines offers significant advantages, including increased production capacity, reduced labor costs, and improved product consistency. The ability to customize machine settings and molds according to specific needs provides greater flexibility for businesses. Additionally, the eco-friendly nature of these machines makes them a sustainable choice for large-scale production. With automation driving efficiency and cost savings, these machines offer long-term value for businesses in the construction industry.

Sobre a KBL Machinery

With nearly 30 years of experience, KBL Machinery specializes in manufacturing automatic fly ash bricks machines, automatic interlocking brick machinese fully automated brick making machines. Our deep industry expertise allows us to offer customized solutions tailored to your specific production needs. We work closely with customers to ensure that our products perfectly align with their requirements. With over 10 years of export experience to more than 50 countries, we are proud to provide efficient, cost-effective brick-making solutions worldwide.