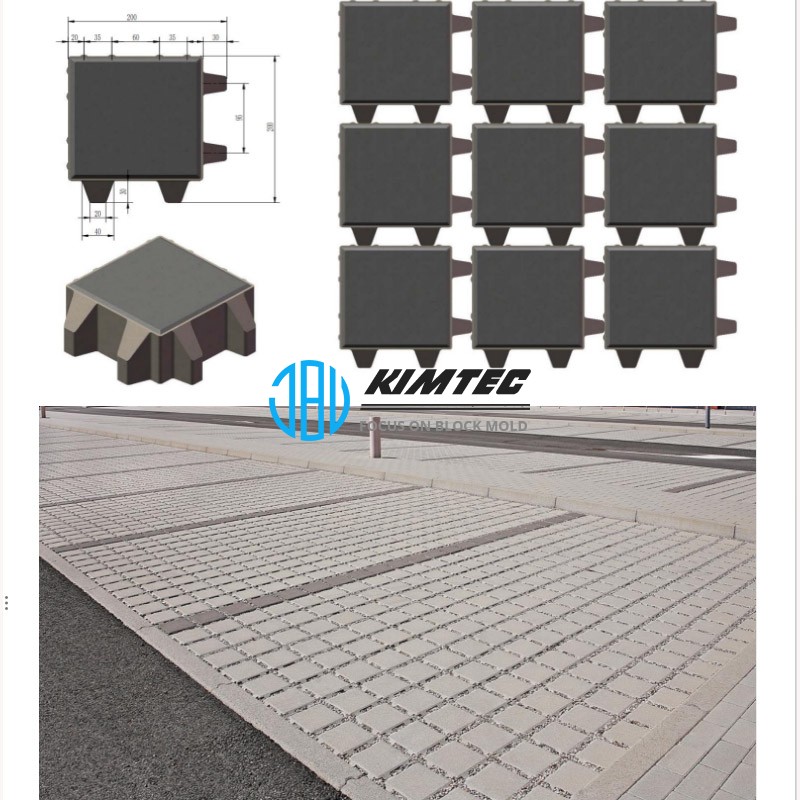

Diamond and L-Shaped Interlocking Concrete Block Molds

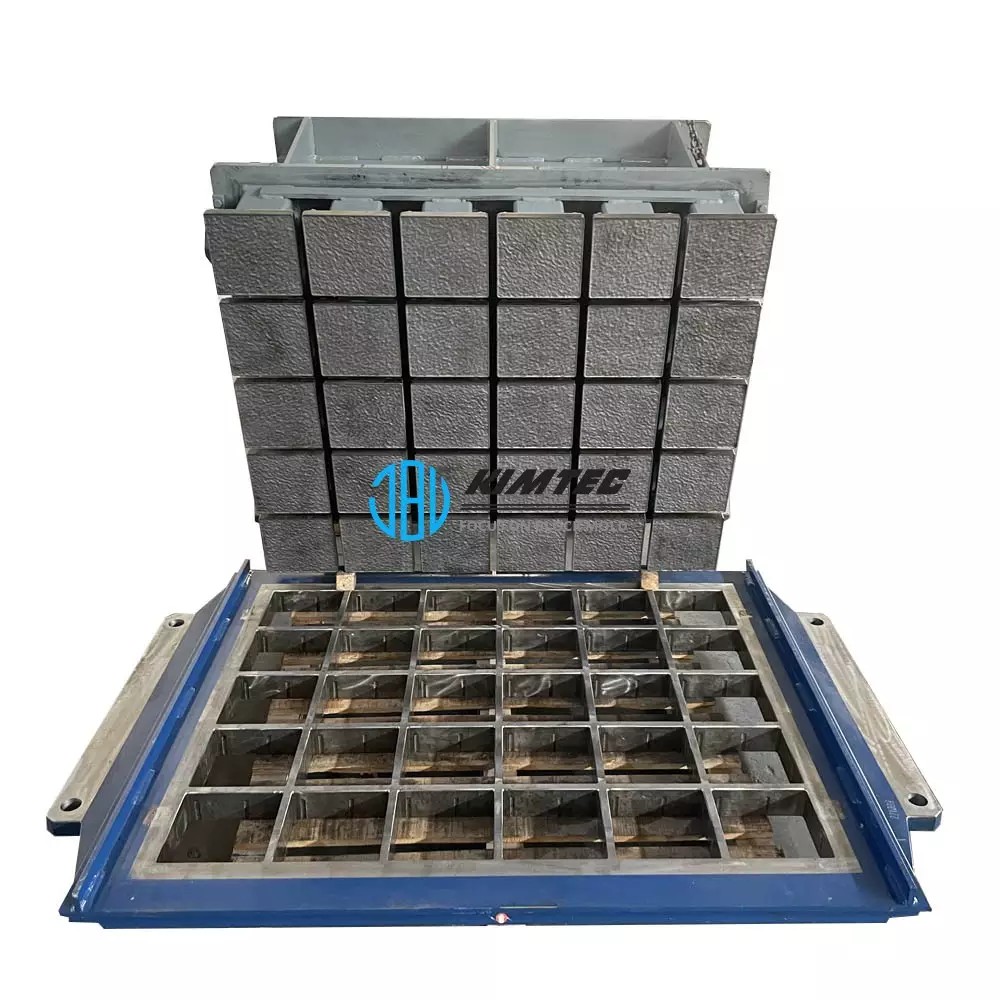

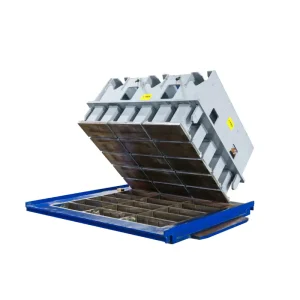

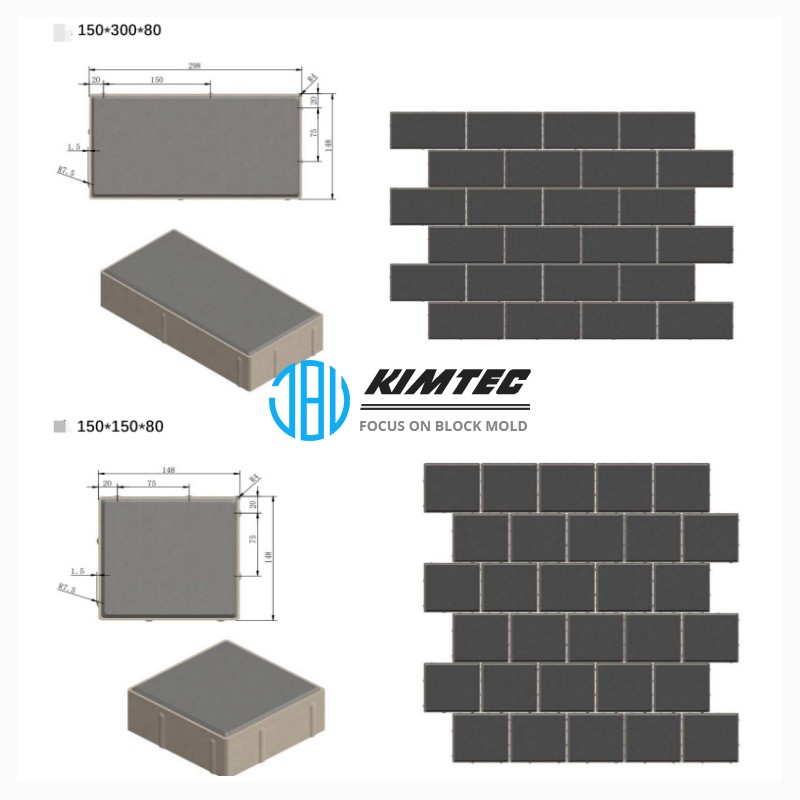

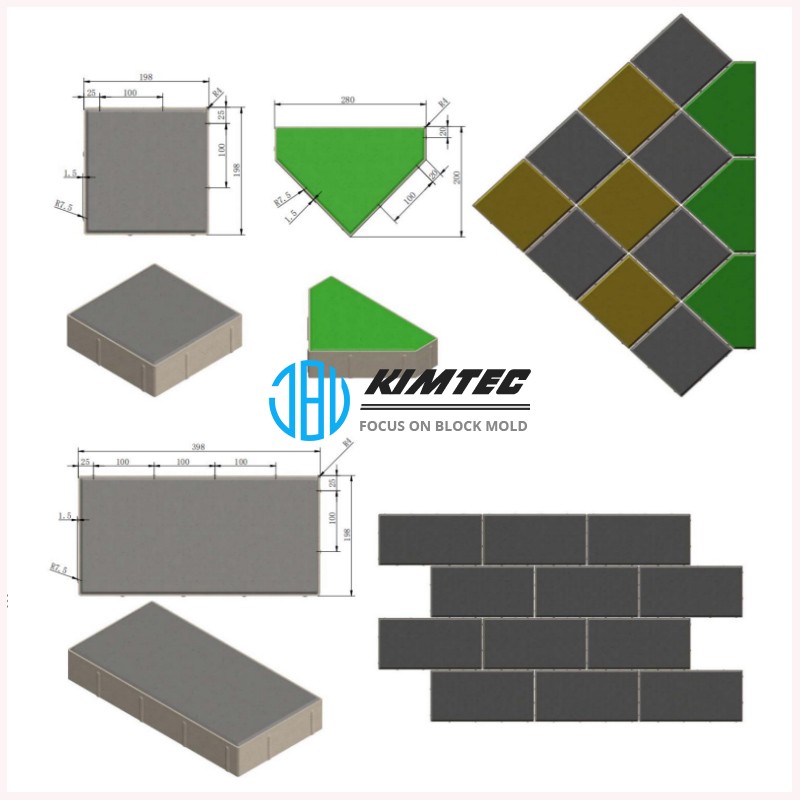

Mold Specifications

Mold Features

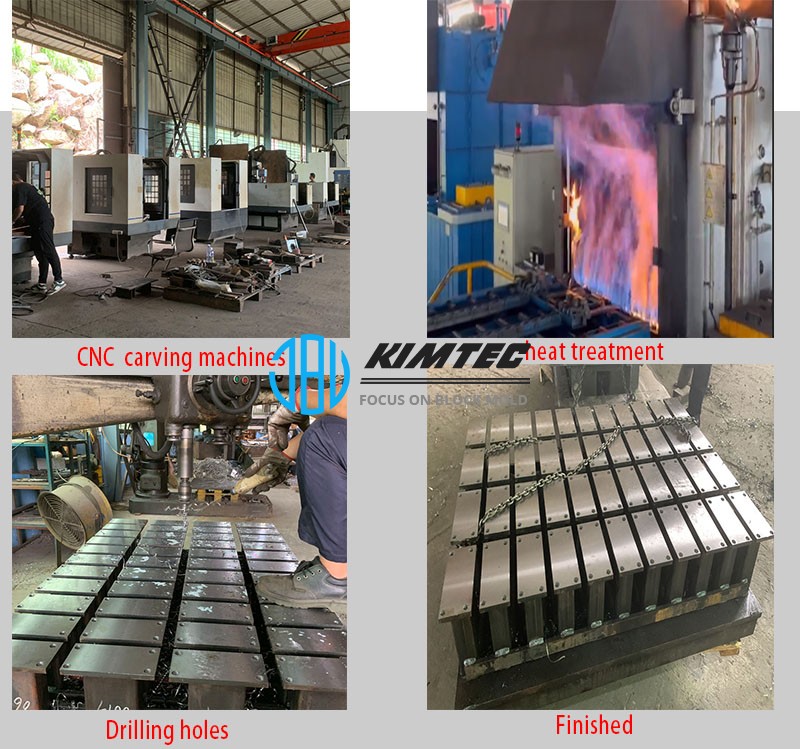

- The most advanced assembly process.

A: We use advanced welding technology and de-stress treatment to ensure precision. If stress remains in the mold material, the cavity and core may deform during use, causing errors in dimensions, shape, and tolerances. This can make qualified products exceed error limits, cause well-matched components to jam, or even render the mold unusable. To prevent this, we minimize deformation during heat treatment and perform tempering after quenching to eliminate internal stress from machining and heat treatment, ensuring the mold functions properly.

B: We maintain a press foot clearance of 0.3-0.8mm for compatibility with your machine.

C: We use high-strength connection bolts with standard parts and anti-loosening treatment for durability.

D: Our standardized assembly process ensures easy replacement of parts.

E: We incorporate high-quality wear-resistant steel plates for longevity.

F: Our molds feature a damping function for smoother operation.

G: We offer digital free surface design for customization.

- To ensure mold durability, we apply carbonitriding heat treatment (60-65HRC).

R: Endurecemos a estrutura da matriz e o pé de prensa a 60-65HRC.

B: We achieve a minimum hardening depth of 1.2mm for enhanced strength.

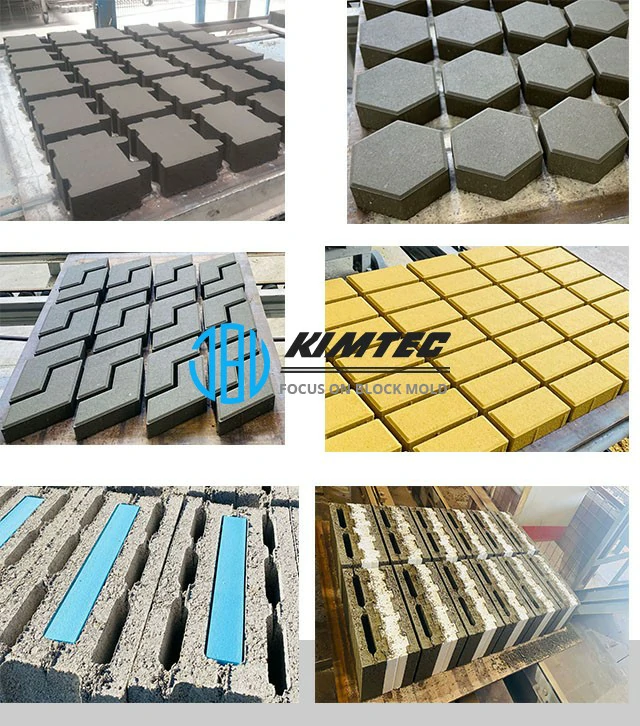

Additional Types of Blocks for Your Reference

Regarding Our Packaging