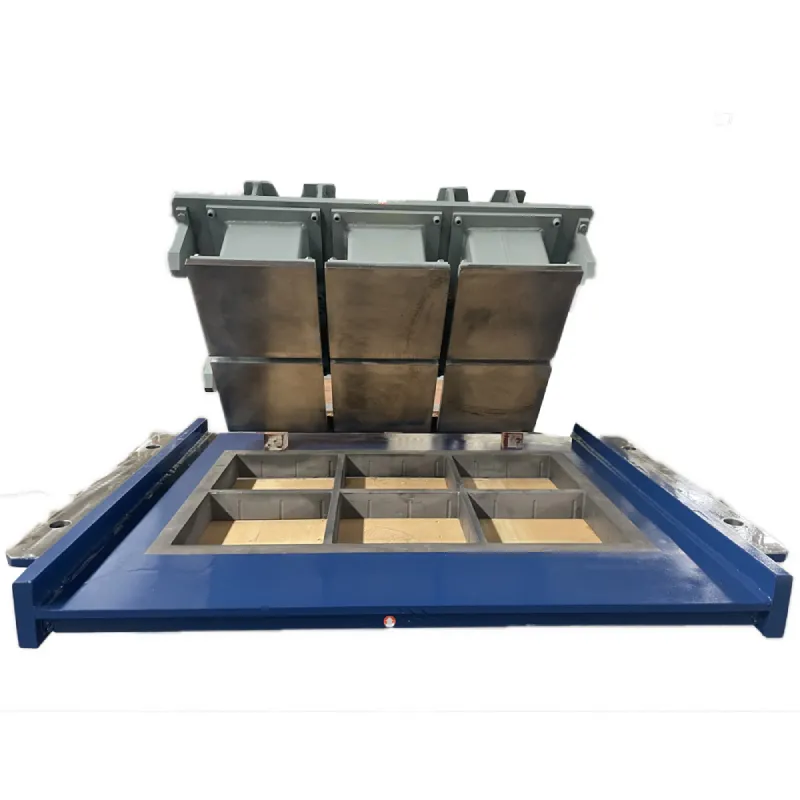

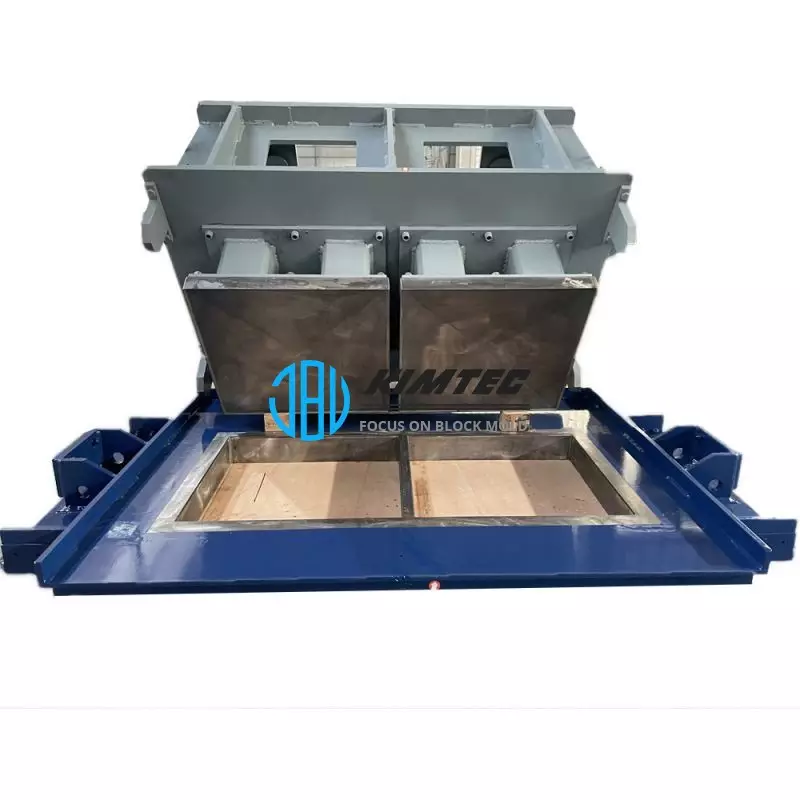

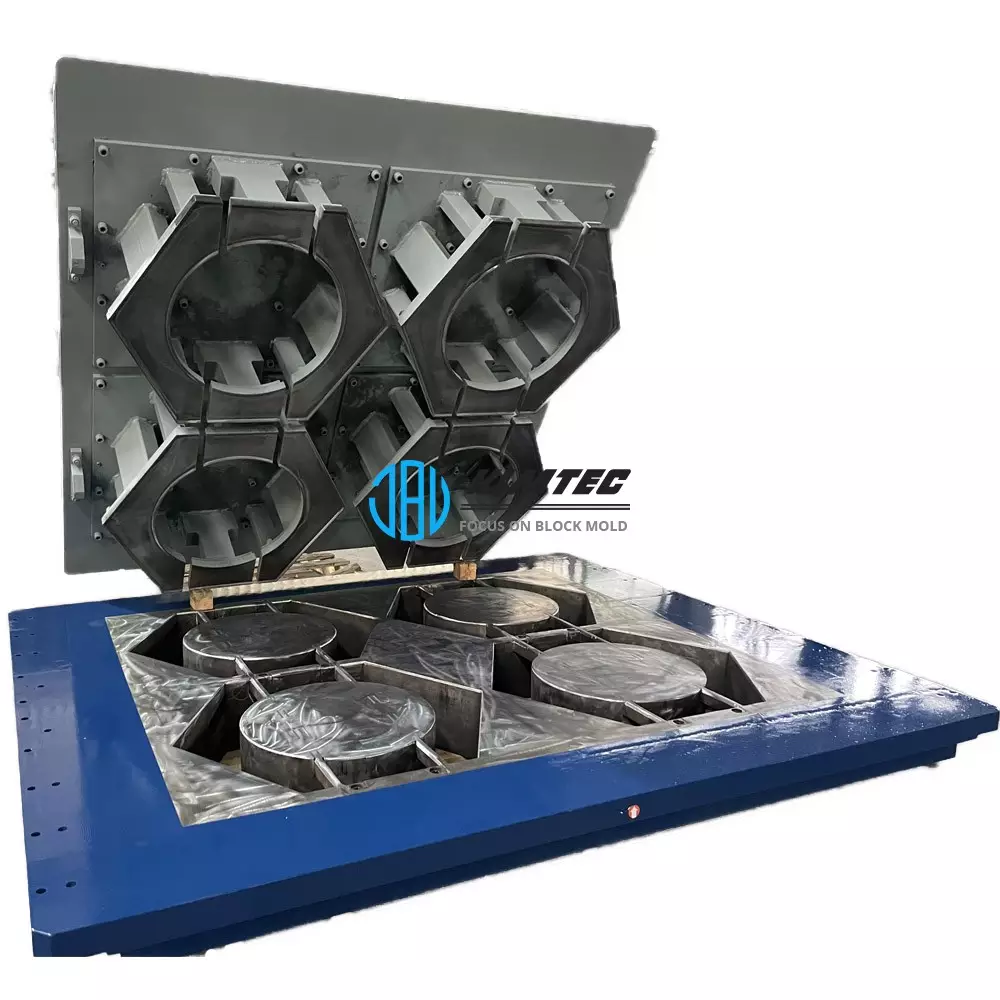

Curbside Sidewalk Brick Mold for Concrete Block Machinery - Made in China

Technical Specifications of Our Molds

Caraterísticas do molde

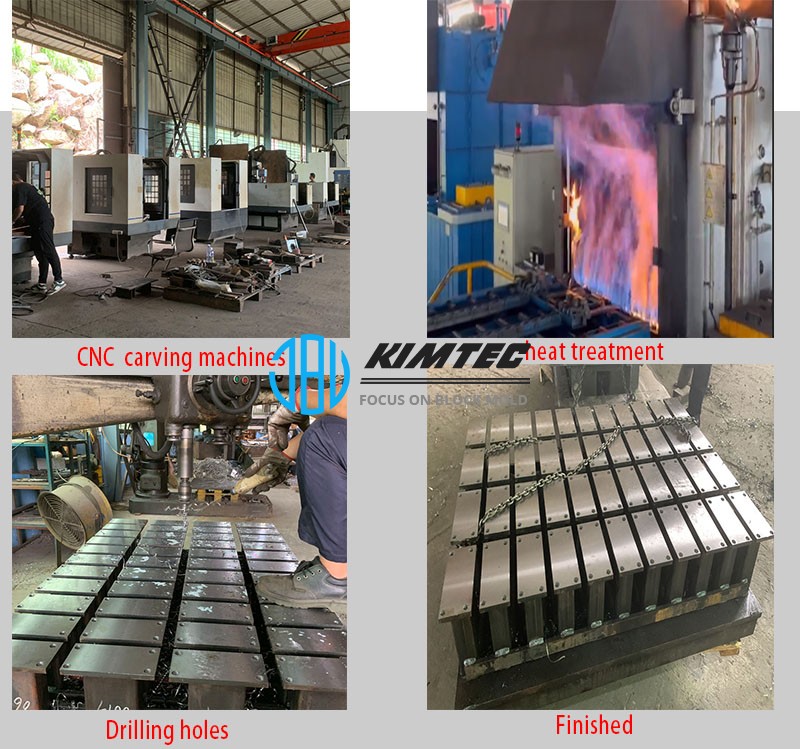

The most advanced assembly process.

A: We utilize advanced welding technology and de-stress treatment. Stress in the mold material can cause deformation in the processed cavity and core, leading to errors in dimensions, shape, and position tolerances. This could result in products exceeding error values or components becoming blocked and stuck. In some cases, they may even become unusable. Therefore, we ensure minimal deformation during heat treatment, with tempering conducted after quenching to eliminate internal stress. This guarantees the mold's normal functionality.

B: The press foot clearance, in relation to the machine, is between 0.3-0.8mm.

C: We use standard parts and anti-loosening treatment for high-strength connection bolts.

D: Our standardized assembly process allows for easy part replacement.

E: We apply high-quality, wear-resistant steel plates.

F: Os nossos moldes possuem uma função de amortecimento.

G: Oferecemos um design de superfície digital livre realizável.

To ensure the mold’s durability, we implement carbonitriding heat treatment (60-65HRC).

A: The die frame and press foot undergo hardening (60-65HRC).

B: A profundidade mínima de endurecimento é de 1,2 mm.

Our Packaging Information

FAQ

- How can I get a quotation?

A. If you have detailed drawings of the block, please send them to us for review. We will provide a quote based on that.

B. If you don’t have detailed drawings, let us know the type of block you need (e.g., hollow block, solid block, etc.), take a picture of the block, and share the dimensions (length, width, thickness in mm).

C. Please provide the size of your pallet.

D. Let us know the size of your tamper head and the height of your down mold.

E. How will your mold connect to your machine for operation? If you have a connection drawing, kindly provide it.

Once we receive this information, we will provide a quote as soon as possible.

- Qual é o prazo de entrega?

For common block molds, the delivery time is 20-25 working days after we receive the deposit. High-end block molds require 30-40 working days.

- How is the transport packing?

We use wooden packing with plastic film, or we can follow the buyer’s specific requirements.

- O molde recebido será compatível com a minha máquina?

We have experience manufacturing molds for many different brands of block machines and keep relevant records. Some molds may already be compatible with your machine.

If needed, you can invite an engineer to your company to take measurements. Alternatively, we can send digital images and take measurements, as many of our customers do.

After confirming the sizing, we guarantee the mold will fit your machine without any issues.

- What are the payment terms?

To complete your order, you need to pay a 50% advance via T/T. The remaining balance is due before loading.

- Como posso contactá-lo?

Pode contactar-nos através do WeChat/WhatsApp em +86-1330506196 ou +86-18960287187. Obrigado!