Paving Mold Machines: Transforming Construction Efficiency and Quality

Paving mold machines are at the forefront of modern construction, revolutionizing the way bricks and blocks are produced. As a top construction equipment supplier, KBL Machinery provides state-of-the-art paving mold machines designed to streamline production, ensuring efficiency and consistency in every product. These machines integrate cutting-edge automation and precision controls, allowing manufacturers to produce high-quality bricks and blocks with uniform size, strength, and durability. By reducing manual labor and optimizing resources, KBL Machinery's paving mold machines help businesses achieve the highest industry standards while significantly lowering production costs.

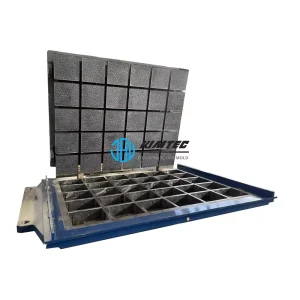

A key advantage of KBL Machinery’s paving mold machines is their ability to handle diverse materials and production requirements. With features like programmable controls and real-time monitoring, these machines can seamlessly produce various products, including Moldes para blocos and Road Brick Moulds, to meet different construction needs. This flexibility allows manufacturers to cater to a wide range of projects, from residential building to large-scale infrastructure. By investing in these versatile machines, companies can adapt quickly to market demands, delivering both standard and custom products with minimal downtime.

In addition to versatility, KBL Machinery’s paving mold machines contribute to sustainable production practices. These machines are designed to use energy efficiently and reduce material waste, making them ideal for eco-conscious construction firms. Many of KBL Machinery’s machines can also work with recycled or eco-friendly materials, aligning with the growing demand for sustainable construction solutions. As a result, companies using KBL's paving mold machines can enhance their environmental footprint and attract clients who prioritize green building.

Why KBL Machinery’s Paving Mold Machines Lead the Market

- Versatility in Product Types: KBL Machinery’s paving mold machines can produce a variety of bricks, including Block Moulds and Moldes para tijolos de estrada, providing flexibility for various construction applications.

- Adaptability to Different Materials: These machines handle a range of raw materials, from clay to recycled compounds, allowing companies to meet diverse project specifications.

- Precisão e consistência: With advanced controls, KBL Machinery’s paving mold machines ensure each block and brick meets strict quality standards, reducing the risk of defects.

- Eficiência energética: Built with energy-saving components, these machines optimize energy use, aligning with eco-friendly construction practices and reducing operational costs.

- Cost-Effectiveness: Combining multiple functions in one machine, KBL Machinery’s equipment lowers investment and maintenance costs, making it a sound choice for construction businesses.

Why KBL Machinery is the Top Construction Equipment Supplier

KBL Machinery is recognized as a leading fornecedor de equipamento de construção for its commitment to quality, innovation, and customer satisfaction. Offering advanced paving mold machines, Block Moulds, and Road Brick Moulds, KBL Machinery provides solutions that are tailored to the needs of the modern construction industry. With a focus on energy efficiency, durability, and comprehensive after-sales support, KBL Machinery enables manufacturers to enhance production, reduce costs, and meet the highest standards.

| Feature | Benefit |

|---|---|

| Versatile Product Range | Machines can produce Moldes para blocos, Moldes para tijolos de estrada, and various other products, catering to diverse construction needs. |

| Multi-Material Compatibility | Handles materials like clay, cement, and recycled compounds, meeting sustainability requirements. |

| High Precision and Quality | Ensures uniform strength and size, reducing waste and improving structural integrity. |

| Eficiência energética | Optimized for low energy consumption, lowering operational costs and supporting eco-friendly practices. |

| Cost Savings | Multi-functional design reduces the need for multiple machines, cutting down on capital investment and maintenance costs. |