Optimizing Production with Advanced Concrete Moulds for Paving Technology

Optimizing production with advanced concrete moulds for paving technology has transformed efficiency and product quality for manufacturers. These modern machines from KBL Machinery incorporate automation and precision controls, minimizing the need for manual intervention and reducing human error. By automating stages such as material mixing, molding, and curing, manufacturers achieve consistent production. This high level of precision allows for the creation of uniform paving products with consistent size, shape, and strength, while also significantly reducing production time. Additionally, real-time monitoring capabilities enable operators to quickly identify and resolve issues, boosting overall production efficiency.

A primary advantage of using advanced concrete moulds for paving technology is the reduction of waste and optimized use of raw materials. KBL Machinery’s modern machines are equipped with intelligent systems that regulate material input, ensuring precise amounts are used for each batch, which helps minimize waste and reduce production costs. Moreover, these machines feature energy-efficient systems like optimized motors and heating, cutting operational expenses and meeting industry demands for sustainable, eco-friendly production methods.

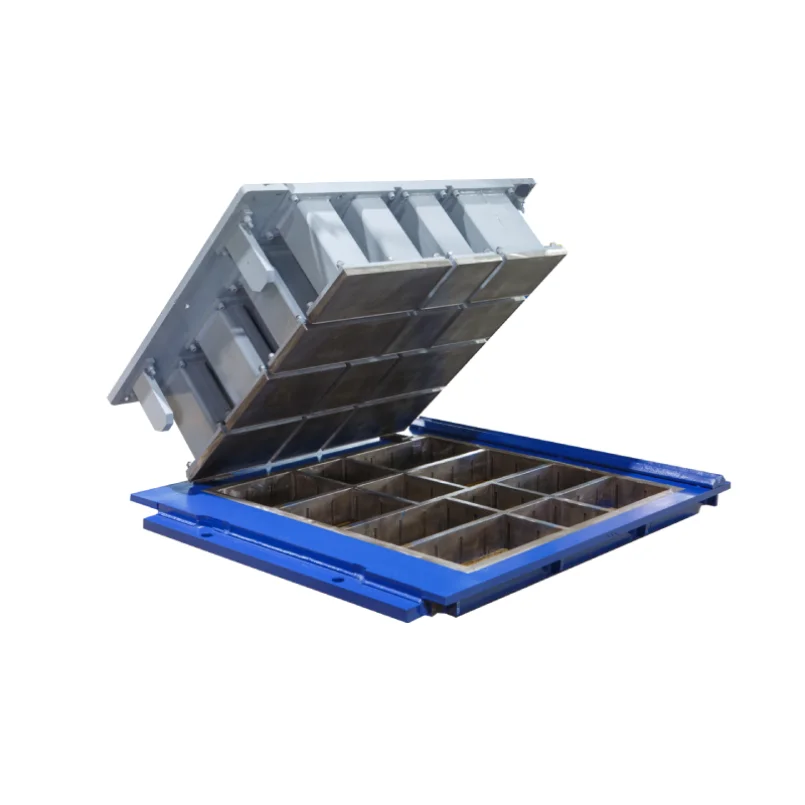

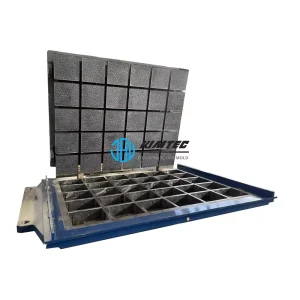

The adaptability of advanced concrete moulds for paving technology is another key benefit, enabling manufacturers to respond quickly to market changes. KBL Machinery’s machines can be reprogrammed to produce various paving styles, including Moldes para blocos and Road Brick Moulds, without extensive downtime or reconfiguration. This flexibility allows manufacturers to meet custom orders and swiftly adapt to market trends, giving them a competitive edge. By integrating these advanced technologies, companies can enhance production processes, respond to evolving customer needs, and maintain leadership in the paving and construction industry.

How Advanced Concrete Moulds for Paving Reduce Production Costs

- Automation of Processes: KBL Machinery’s advanced concrete moulds for paving automate most production steps, from raw material mixing to molding and stacking. This automation lowers labor costs by reducing reliance on manual processes, improving efficiency, and minimizing errors. Automated systems operate with minimal supervision, allowing companies to maximize output without expanding their workforce.

- Eficiência energética: Modern concrete moulds for paving are built with energy-saving technologies like optimized motors, intelligent heating, and power management controls. These machines consume less energy, reducing electricity and fuel expenses. Energy-saving modes adjust power use based on production needs, preventing unnecessary energy consumption during downtime and supporting sustainable practices.

- Minimization of Material Waste: Advanced technology enables precise control of raw material inputs. Automated dosing systems ensure the correct amount of materials, such as cement or sand, is used for each batch, reducing waste and material costs. This is particularly beneficial for high-volume production, where even minor reductions in waste can lead to substantial savings over time.

- Increased Production Speed: KBL Machinery’s machines are designed for high-speed production, allowing companies to complete production cycles faster and handle larger orders. This faster output reduces production time per batch, leading to lower operational costs and greater market competitiveness.

- Reduced Maintenance Costs: Built for durability, these machines are designed to withstand heavy use with minimal wear. Self-diagnostic systems monitor components and alert operators to potential issues, enabling preventive maintenance. By addressing minor issues early, manufacturers can reduce costly repairs and minimize downtime.

About KBL Machinery: Your Reliable Construction Equipment Supplier

As a premier fornecedor de equipamento de construção, KBL Machinery is dedicated to delivering advanced, high-quality solutions for the construction and paving industries. With a focus on innovation, we provide a range of equipment, including concrete moulds for paving, Block Moulds, and Moldes para tijolos de estrada, all designed to enhance efficiency, reduce costs, and support sustainable practices. Our commitment to customer satisfaction extends to providing exceptional after-sales support, including training, technical assistance, and access to spare parts. With a team of experienced professionals and cutting-edge technology, KBL Machinery is your trusted partner for success in a competitive market.

| Key Feature | Description |

|---|---|

| Automation of Processes | Reduces manual labor and improves efficiency by automating steps like mixing, molding, and stacking. |

| Eficiência energética | Designed with energy-saving features that lower electricity and fuel costs, contributing to eco-friendly operations. |

| Minimization of Material Waste | Precise control over raw materials reduces waste and lowers costs, especially in high-volume production. |

| Increased Production Speed | High-speed production capabilities reduce batch times, increasing output and competitiveness. |

| Reduced Maintenance Costs | Durable design and self-diagnostic systems minimize wear, reduce repair costs, and extend equipment lifespan. |