O que é um molde de betão?

4 de setembro de 2024

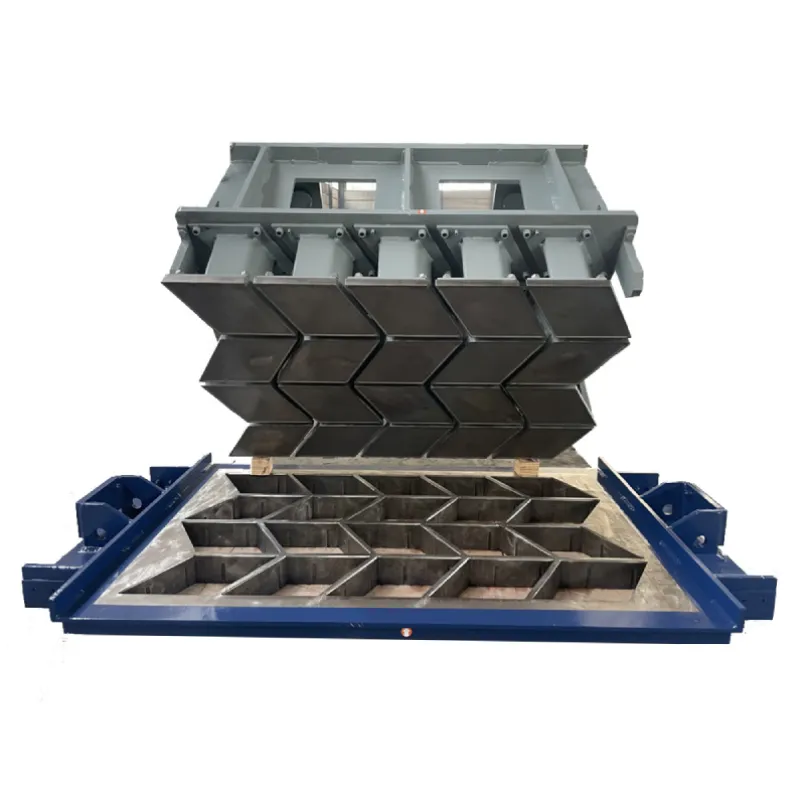

In the construction industry, the term “concrete mould” refers to a crucial tool used for shaping concrete into specific forms, enabling the creation of various structures and products. A concrete mould is essentially a hollow container into which liquid concrete is poured, allowed to set, and then removed to reveal a solid concrete product. These molds are indispensable in producing a wide range of concrete items, from simple blocks to intricate architectural elements.

How Concrete Moulds Work

Concrete moulds are designed to hold wet concrete in place until it hardens into the desired shape. The process begins with the preparation of a concrete mixture, which is then poured into the mould. The mould can be made of various materials, including steel, plastic, or rubber, depending on the complexity and size of the concrete item being produced. After the concrete is poured, it is vibrated to remove air bubbles and ensure even distribution. Once the concrete has set and cured, the mould is removed, revealing a solid, finished product.

Types of Concrete Moulds

Molds for Concrete Blocks: These are used to produce concrete blocks, which are widely used in building construction. Molds for concrete blocks come in various sizes and designs, allowing for the production of standard and custom-shaped blocks to meet specific architectural needs.

Architectural Concrete Moulds: These are used to create decorative elements such as columns, balustrades, and ornate facades. These moulds are often more intricate and detailed, enabling the production of aesthetically pleasing concrete components.

Paving Moulds: Used for producing concrete pavers and tiles, these moulds help in creating uniform and durable surfaces for driveways, walkways, and patios.

The Importance of Concrete Moulds in Construction

Concrete moulds play a vital role in the construction industry by ensuring that concrete products are produced with precision, consistency, and efficiency. The use of high-quality molde de betãos not only speeds up the production process but also enhances the structural integrity and appearance of the final product. As the demand for custom and aesthetically appealing concrete products grows, the importance of reliable and durable concrete moulds becomes increasingly evident.

What materials are commonly used to make concrete moulds?

Concrete moulds, also known as formworks, are commonly made from a variety of materials, each with its own unique characteristics and applications. The most commonly used materials for concrete moulds include:

Wood: Wood is a traditional and widely used material for molde de betãos due to its ease of availability, workability, and relatively low cost. It can be easily cut, shaped, and assembled into complex forms. However, wood moulds may require frequent maintenance and replacement due to wear and tear, moisture absorption, and potential for warping.

Steel: Steel moulds are known for their durability, strength, and reusability. They can withstand the rigors of concrete pouring and curing processes and can be used for multiple pours without significant degradation. Steel moulds are often used for large-scale projects or where precision and durability are critical. However, they may be more expensive than other materials and require specialized equipment for fabrication and handling.

Plastic: Plastic moulds, particularly those made from materials like ABS, are becoming increasingly popular due to their lightweight, durability, and ease of cleaning. They can be used multiple times (sometimes more than 85 times, as mentioned in some sources) and are well-suited for laboratory testing and small-scale projects. Plastic moulds are also less prone to moisture absorption and warping compared to wood.

Aluminum: Aluminum moulds offer a good balance between durability and cost. They are lightweight, easy to handle, and can be reused multiple times. Aluminum moulds are particularly suitable for projects where weight is a concern or where quick turnaround times are required.

Fiberglass: Fiberglass moulds are known for their strength, durability, and resistance to moisture and temperature extremes. They are often used for complex shapes and surfaces that require a high degree of precision. Fiberglass moulds can also be used for both concrete and other materials, making them versatile in their applications.