Expert Insights: How to Choose the Best Kerb Stone Moulds for Your Business

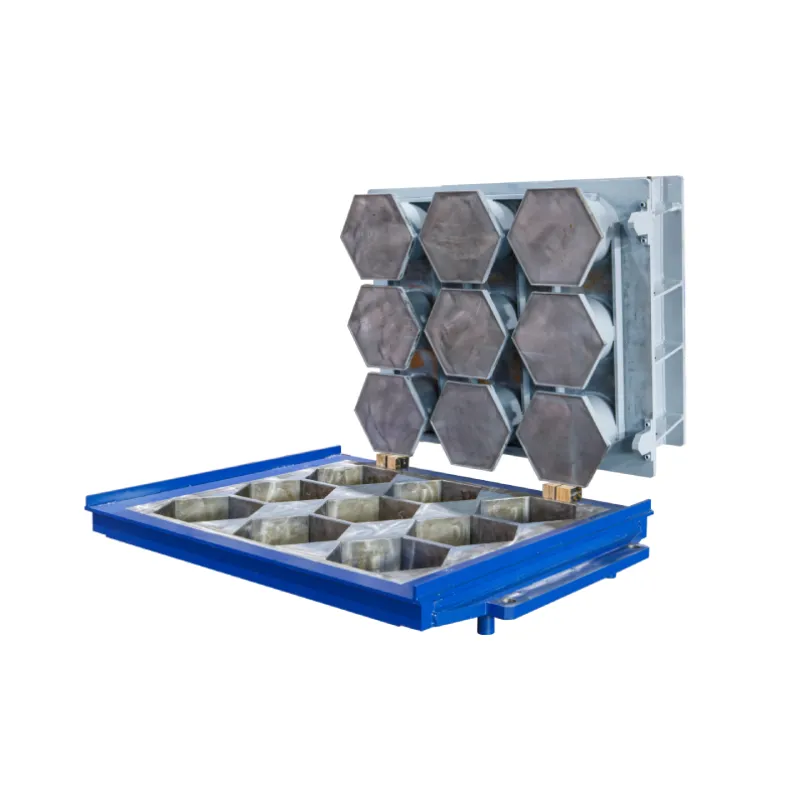

Selecting the right kerb stone moulds is crucial for maintaining high production efficiency and achieving consistent product quality. KBL Machinery, a leading construction equipment supplier, advises that the first consideration should be the specific needs of your production line. Whether your focus is on high-volume manufacturing or specialized block designs, it's essential to select kerb stone moulds that align with your production objectives. Precision-engineered Block Moulds from KBL Machinery ensure that each kerb stone meets exact dimensions, which improves the overall integrity of the product while minimizing material waste and production errors.

Durability is another critical factor. KBL Machinery offers kerb stone moulds made from high-grade materials, such as reinforced steel, ensuring they withstand continuous heavy-duty use. This durability extends the lifespan of the moulds, reducing the need for frequent replacements and lowering long-term operational costs. Moreover, the robust nature of these Block Moulds ensures consistent production, which is especially beneficial for businesses engaged in large-scale construction projects.

Finally, customization is an essential element. KBL Machinery provides customizable mould solutions that allow businesses to tailor Road Brick Moulds and kerb stone moulds to their specific project requirements. Whether you need unique sizes, shapes, or configurations, custom moulds provide flexibility while ensuring top-notch production performance. With these customized solutions, your business gains a competitive edge by delivering high-quality kerb stones that meet industry standards.

How to Avoid Common Kerb Stone Mould Defects in Production

Maintaining production quality is crucial when using kerb stone moulds. Here are a few best practices from KBL Machinery, a trusted construction equipment supplier:

| Common Issue | Solution Provided by KBL Machinery |

|---|---|

| Improper Mould Alignment | Ensure proper alignment during setup to avoid misaligned blocks. KBL Machinery's Block Moulds are designed for easy alignment, which minimizes production errors. |

| Dirty Moulds | Regular cleaning after each production cycle is essential. Use non-abrasive tools to clean kerb stone moulds and maintain surface quality. |

| Incompatible Raw Materials | Ensure that the raw materials used are compatible with the kerb stone moulds. This prevents issues like cracks and deformations. KBL Machinery provides guidance on material compatibility. |

| Excessive Production Pressure | Monitoring pressure during the moulding process helps avoid uneven blocks. KBL Machinery offers calibration support to ensure pressure is balanced. |

| Wear and Tear | Regularly check for signs of wear, such as surface degradation. KBL Machinery's Block Moulds are designed for durability, but routine inspections extend their operational life. |

| Lack of Lubrication | Consistent lubrication is necessary for moving components. KBL Machinery recommends high-quality lubricants to avoid friction-related damage. |

By following these practices, businesses can significantly reduce defects and ensure smooth production when using kerb stone moulds.

Why Choose KBL Machinery

Partnering with KBL Machinery means choosing a reliable construction equipment supplier known for its commitment to quality, innovation, and customer satisfaction. Our advanced Block Moulds, Road Brick Moulds, and kerb stone moulds are designed for precision, durability, and long-term efficiency. Whether you're looking for high-performance moulds or customized solutions to fit your specific needs, KBL Machinery delivers products that enhance your production process. With dedicated customer support and engineering expertise, we ensure that every solution is tailored to help your business achieve superior performance and sustained success.

When you choose KBL Machinery, you are investing in a partner that is focused on your long-term growth, product quality, and overall success in the construction industry.