News

-

Data-Backed: 5 Key Brick Strength Influencing Factors to Master in 2026

Read moreAbstract The compressive strength of concrete bricks is a foundational pillar of structural integrity, yet it is governed by a complex interplay of variables. This analysis examines the primary brick strength influencing factors, presenting a systematic exploration for producers, particularly in the rapidly developing markets of Southeast Asia and the Middle East. It posits that […]

-

A Proven 5-Point Checklist: Evaluating Molding Accuracy Standards in 2026

Read moreAbstract An examination of molding accuracy standards for concrete block manufacturing reveals a complex interplay between mechanical engineering, material science, and process control. The dimensional consistency of concrete blocks is not a product of a single machine function but rather the result of a harmonized system. This analysis investigates the constituent elements that determine the […]

-

A Proven 5-Step Guide to Concrete Brick Mix Ratio Optimization: Cut Costs in 2026

Read moreAbstract This analysis provides a comprehensive examination of concrete brick mix ratio optimization, presenting a systematic, five-step methodology for manufacturers in 2026. It moves beyond rudimentary volumetric recipes to a scientifically grounded approach centered on material science, performance testing, and process control. The core argument is that optimizing the mix is not a singular event […]

-

A Data-Backed Guide: 5 Factors Influencing Machine-made brick compressive strength

Read moreAbstract The structural integrity of modern construction relies heavily on the quality of its constituent components, with machine-made bricks being a fundamental element. This document examines the multifaceted nature of machine-made brick compressive strength, a paramount indicator of a brick's ability to withstand loads without failure. It explores the five primary determinants influencing this property: […]

-

A Practical Guide to Fly Ash Utilization in Brick Machines: 5 Ways to Boost Your ROI in 2026

Read moreAbstract The global construction industry, particularly in the rapidly developing regions of Southeast Asia and the Middle East, stands at a pivotal moment in 2026, facing dual pressures of resource scarcity and environmental accountability. This analysis examines the paradigm shift toward sustainable building materials, focusing specifically on fly ash utilization in brick machines. Fly ash, […]

-

Expert Guide to Brick Raw Materials Composition: 7 Key Ratios for High-Quality Blocks in 2026

Read moreAbstract The production of high-quality, durable bricks hinges on the precise formulation of their constituent raw materials. An optimal brick raw materials composition is not a universal formula but a carefully calibrated recipe that accounts for material science, economic constraints, and local environmental conditions. This guide examines the fundamental principles governing the selection and proportioning […]

-

A 7-Step Practical Guide: The 2026 Automated Brick Production Line Workflow for High-Efficiency Plants

Read moreAbstract The evolution of construction material manufacturing has seen a significant shift towards automation, enhancing efficiency, quality, and safety. This document examines the complete operational sequence of a modern automated brick production line workflow as of 2026. It provides a granular analysis of each stage, commencing with the precise digital batching of raw materials like […]

-

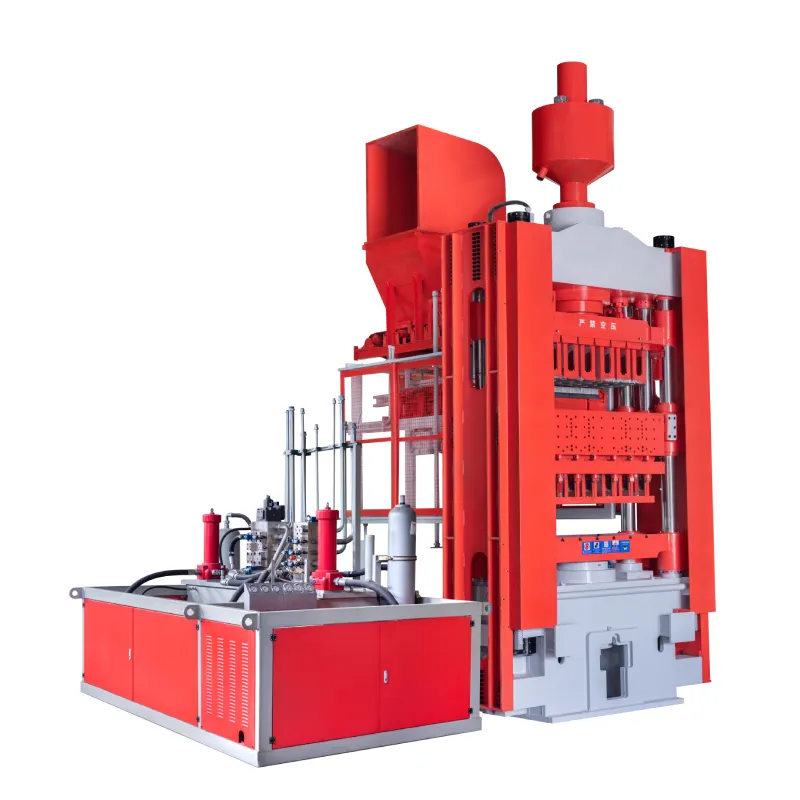

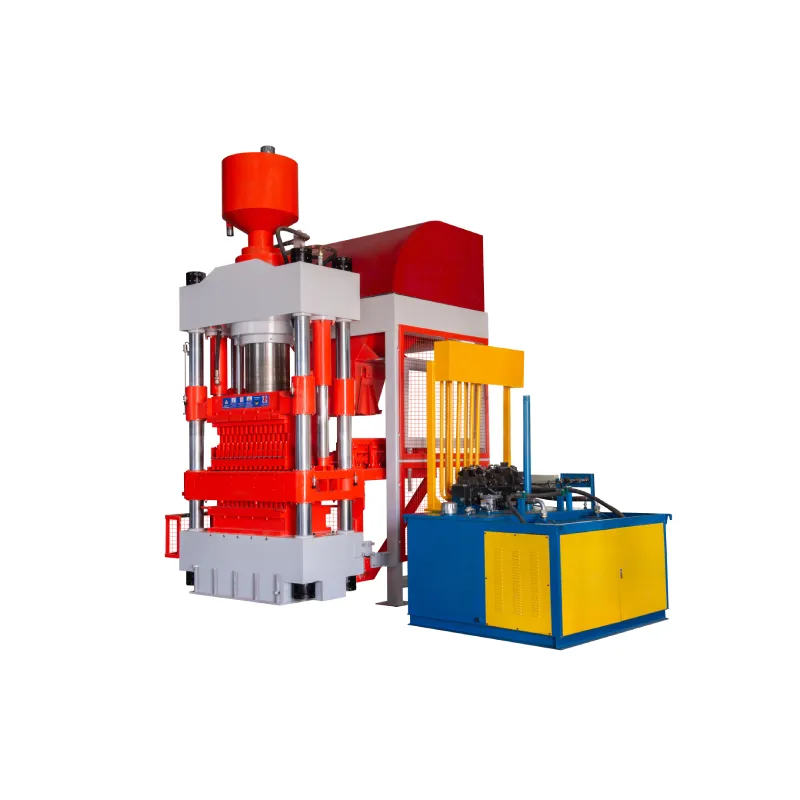

![QT12-15-BrickBlock-Making-Machine-1[1] A Proven Guide to Multi-size brick production capability: Boost Project ROI by 35% in 2026](https://www.kblmachinery.com/wp-content/uploads/2026/02/QT12-15-BrickBlock-Making-Machine-11.webp)

A Proven Guide to Multi-size brick production capability: Boost Project ROI by 35% in 2026

Read moreAbstract The evolution of construction machinery reflects a broader industrial shift from rigid specialization towards dynamic versatility. This analysis examines the operational and economic implications of multi-size brick production capability in modern concrete block machines, particularly within the rapidly developing markets of Southeast Asia and the Middle East. It posits that the ability of a […]

-

A 5-Step Guide to Batching Plant Integration Feasibility: Data-Backed ROI for 2026

Read moreAbstract The decision to integrate an automated batching plant into an existing concrete block production line represents a substantial capital investment with profound operational implications. This analysis explores the multifaceted nature of assessing the feasibility of such an integration, particularly for enterprises in Southeast Asia and the Middle East. A systematic evaluation framework is proposed, […]

-

5 Proven Factors That Determine Hourly Brick Production Rate: A 2026 Guide for SEA & Middle East

Read moreAbstract An examination of the factors governing the hourly output of brick manufacturing reveals a complex interplay between mechanical specifications, material science, operational management, and environmental conditions. This analysis focuses on the determinants of the hourly brick production rate for concrete block-making facilities, particularly within the economic and climatic contexts of Southeast Asia and the […]