포장용 돌 몰드

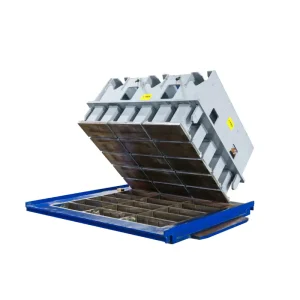

Kimberly Machinery’s Paving Stone Moulds: Built for Long-Term Durability

Kimberly Machinery’s 포장용 스톤 몰드 are specifically designed for extended performance, ensuring that they withstand the demands of high-volume production. Made from top-grade materials, these moulds resist wear and tear, minimizing maintenance and replacement costs. Manufacturers can rely on these durable moulds to boost production while maintaining the highest paving stone quality.

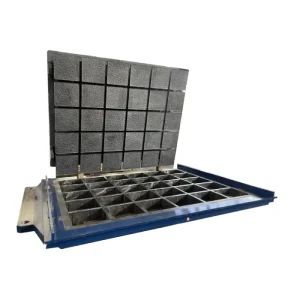

Precision and Consistency in Every Cycle

Each moulding cycle guarantees precision, resulting in uniform stone sizes and shapes. This consistency is crucial for flawless installations, particularly in paving projects where design and fit are key. Whether used for sidewalks, driveways, or large public spaces, the uniformity of these stones ensures both aesthetic appeal and structural stability, reducing the need for future repairs or adjustments.

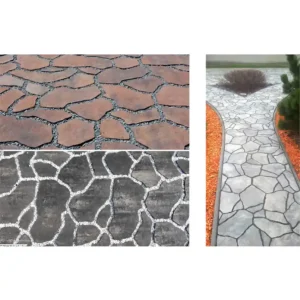

Versatility for Customization

Kimberly Machinery’s Paving Stone Moulds offer versatility, enabling builders to create a variety of stone sizes, shapes, and patterns. This customization ensures that the final product aligns perfectly with the project’s architectural design. The moulds’ flexibility, combined with their durability, makes them an essential tool for delivering high-quality paving solutions in diverse environments.

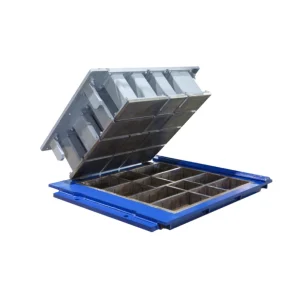

The Future of Automated Block Moulding Processes

- Increased Precision: Automated block moulding ensures exact measurements, minimizing errors and enhancing overall quality.

- Faster Production: Automation speeds up production cycles, allowing for a larger volume of blocks in less time, meeting tight deadlines.

- Reduced Labor Costs: Automation reduces manual labor, enabling businesses to save on costs and focus on skilled tasks.

- Consistency in Block Quality: Automated systems guarantee uniformity in size, shape, and strength, ensuring structural integrity in large-scale projects.

- Smart Technology Integration: Future moulds will incorporate AI and IoT, enabling real-time monitoring, predictive maintenance, and remote operation for more efficient production.

About Kimberly Machinery

Kimberly Machinery is an industry leader in construction machinery, specializing in the design and manufacturing of high-performance Brick and 블록 몰드. With years of experience, we provide cutting-edge solutions that enhance productivity, reduce costs, and ensure precision. Our customizable equipment meets the diverse needs of businesses globally, making Kimberly Machinery a trusted name for durable construction solutions. Customer satisfaction and innovation drive everything we do. We offer reliable Concrete Block Making Machines and seamless integration of production lines for any scale of operation.