Fully Automated Brick Making Machines: A New Era of Efficient Production

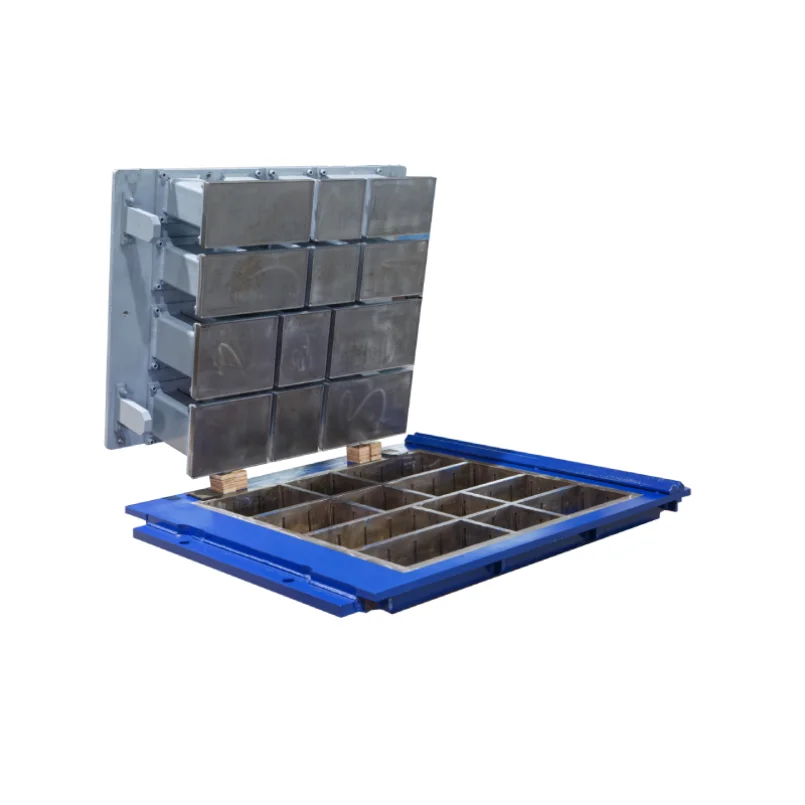

Fully automated brick making machines are revolutionizing the production of pavers molding and other brick types by introducing high-tech automation to the process. These machines use advanced robotics, sensors, and AI-driven controls to automate every step of production, from mixing raw materials to molding, drying, and stacking. As a result, pavers molding is streamlined, ensuring that each brick is produced with consistent quality, size, and shape. The precision of these machines minimizes human error, reduces waste, and enhances the overall efficiency of the production line.

With the ability to operate continuously with minimal downtime, automated machines offer unmatched productivity. Equipped with real-time monitoring systems, they can detect issues early, reducing the risk of disruptions and costly repairs. By optimizing raw material usage and energy consumption, these machines significantly lower production costs, making them a sound investment for large-scale manufacturing. Additionally, for companies producing a range of bricks, including block moulds and road brick moulds, fully automated brick making machines offer the flexibility needed to meet varying market demands efficiently.

These machines are also adaptable, allowing manufacturers to quickly shift between different brick types without requiring extensive reconfiguration. Whether producing block moulds, pavers molding, or custom road brick moulds, automated machines give manufacturers the flexibility to respond to market trends and custom orders quickly. The versatility of these machines ensures that businesses can stay competitive, offering a range of products while maintaining high-quality standards.

Maintenance and Repair of Brick Machines: Best Practices for Extending Equipment Lifespan

- Regular Inspection and Cleaning: To prolong the life of brick making machines used for pavers molding and road brick moulds, regular inspection and cleaning are essential. Operators should check for wear on components like belts, gears, and hydraulic systems. Routine cleaning prevents raw materials from building up and ensures smooth operation, avoiding costly repairs and downtime.

- Lubrication of Moving Parts: Proper lubrication is critical to maintaining the efficiency of moving parts such as gears, bearings, and chains. By reducing friction and preventing overheating, lubrication extends the lifespan of machines that produce block moulds and road brick moulds. Operators should follow the machine manufacturer's lubrication guidelines to ensure optimal performance.

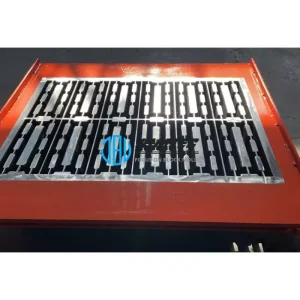

- Monitor and Replace Worn Parts: Continuous monitoring of critical components like pavers molding molds, belts, and seals can prevent unexpected breakdowns. Promptly replacing worn parts ensures the machine remains operational, minimizing downtime and preventing major repair costs.

- Calibrate the Machine Periodically: For machines producing block moulds, pavers molding, and other custom designs, regular calibration is vital to maintaining production consistency. By recalibrating sensors and control systems, manufacturers ensure their bricks meet desired specifications, reducing defects and maintaining high quality.

- Employee Training on Operation and Safety: Proper operator training is key to extending the life of brick making machines. Operators must be trained not only on machine operation but also on how to troubleshoot common issues related to road brick moulds and pavers molding production. Well-trained staff can quickly address minor issues, reducing the risk of significant equipment damage and improving workplace safety.

선택해야 하는 이유

At KBL Machinery, we are a trusted 건설 장비 공급업체 specializing in high-performance brick making machines. Our automated systems, designed for producing everything from pavers molding to block moulds, help manufacturers streamline production processes, reduce waste, and increase output. Our commitment to innovation and sustainability means that we offer energy-efficient solutions tailored to the specific needs of our clients. Alongside our cutting-edge products, KBL Machinery provides exceptional after-sales support, including training, maintenance, and replacement parts, ensuring that your operations run smoothly and efficiently. By partnering with us, you gain a reliable ally in the competitive building materials industry.