전문가 인사이트: 최고를 선택하는 방법 Paving Mold 비즈니스용

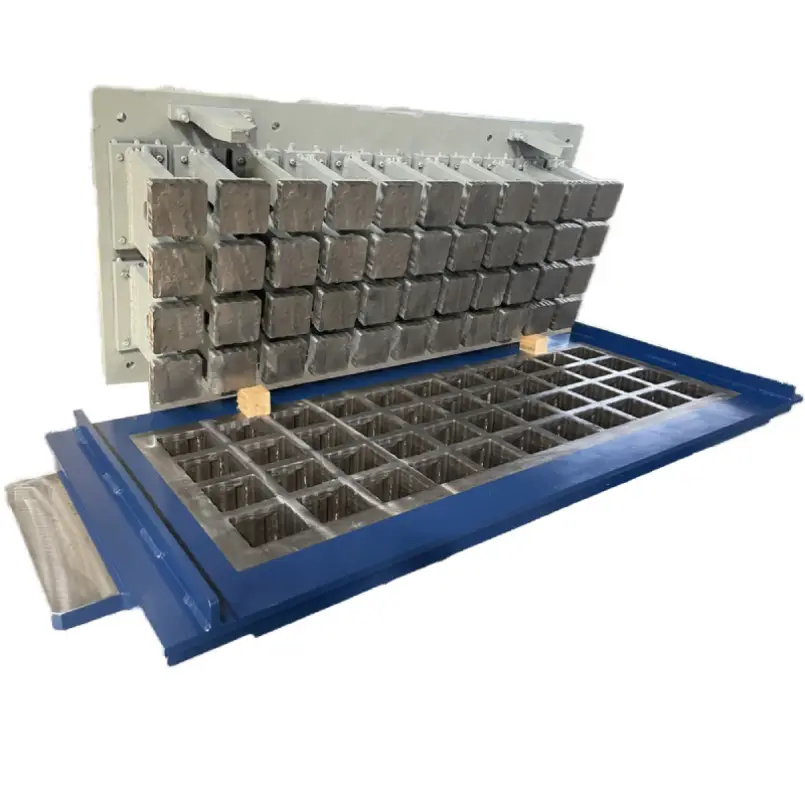

Selecting the best paving mold for your business is a critical decision that can significantly impact production efficiency and product quality. KBL 기계신뢰할 수 있는 건설 장비 공급업체, emphasizes the importance of aligning your mould selection with your production goals. Whether you need moulds for high-volume manufacturing or specialized block designs, it's essential to select 블록 몰드 that fit the needs of your production line. KBL 기계의 precision-engineered moulds ensure consistent block size and quality, reducing errors and material waste while improving the structural integrity of the finished product.

Durability and material quality are also key considerations when selecting a paving mold. KBL 기계 오퍼 로드 브릭 몰드 made from high-grade steel and other robust materials that withstand continuous use in heavy-duty environments. The longer lifespan of these moulds reduces the need for frequent replacements, helping lower long-term operational costs. Additionally, durable 블록 몰드 contribute to maintaining consistent production output, which is vital for businesses handling large-scale projects.

Customization is another critical factor. KBL 기계 provides customizable paving molds 그리고 로드 브릭 몰드 tailored to your business's unique needs. Whether you need specific block sizes, shapes, or configurations, these moulds offer flexibility in production, ensuring both efficiency and product excellence. Choosing the right paving mold not only optimizes production but also gives you a competitive edge in the marketplace.

| Key Consideration | Importance in Choosing a Paving Mold |

|---|---|

| Material Quality | Ensures durability, reducing frequent replacements. |

| Precision | Guarantees consistent block size, minimizing defects. |

| 사용자 지정 | Allows for tailored solutions to meet specific project needs. |

| 내구성 | Provides long-term value by reducing maintenance and replacement costs. |

How to Avoid Common Defects in Paving Molds

| Defect | Prevention Strategy by KBL 기계 |

|---|---|

| Misalignment | Proper alignment of the paving mold during setup is critical to achieve uniform blocks. KBL 기계 designs precision-engineered 블록 몰드 for easy alignment, ensuring consistency. |

| Contamination | Dirt and leftover material can cause surface defects. KBL 기계 recommends regular cleaning of the paving molds after each production cycle to maintain their integrity. |

| Incompatible Materials | The raw materials must match the paving mold specifications to avoid cracks or deformation. KBL 기계 advises using compatible materials to prevent excessive wear on the 블록 몰드. |

| Excessive Pressure | High pressure during production can lead to defects in the blocks. KBL 기계 provides calibration support to ensure that optimal pressure is maintained. |

| 마모 및 손상 | Even high-quality paving molds may experience wear over time. Regular inspections help identify signs of wear, allowing timely maintenance or replacement. |

| Lubrication | 일관된 윤활 paving molds 마찰로 인한 손상을 방지하기 위해 움직이는 부품이 있는 경우 필요합니다. KBL 기계 는 원활한 작동을 위해 고품질 윤활유 사용을 권장합니다. |

선택해야 하는 이유 KBL 기계 당신의 건설 장비 공급업체

선택 KBL 기계 의 리더와 파트너십을 맺는다는 것은 건설 장비 공급업체 업계에서 고품질의 혁신적인 제품을 제공하는 것으로 유명합니다. 고급 기능을 제공하는 데 중점을 두고 paving molds, 블록 몰드및 로드 브릭 몰드는 모든 제품이 최고의 효율성, 내구성, 정밀성을 갖출 수 있도록 설계되었습니다. 전문 엔지니어 팀과 전담 고객 지원팀의 지원을 받습니다, KBL 기계 는 각 고객의 고유한 요구사항을 충족하는 맞춤형 솔루션을 제공합니다. 품질과 고객 만족을 위한 당사의 노력은 기업이 우수한 생산 성과와 장기적인 성공을 달성할 수 있도록 보장합니다.