What type of cement is used in paver moulds?

9월 4, 2024

In the production of high-quality paving materials, selecting the right type of cement for paver moulds is crucial. The choice of cement impacts the strength, durability, and overall performance of the final product. Paver moulds, paving concrete molds및 포장 블록 몰드 all require specific types of cement to achieve the best results in terms of both aesthetics and functionality.

Types of Cement Used in Paver Moulds

Portland Cement: This is the most commonly used type of cement in the production of paver moulds. Its versatility and strong binding properties make it ideal for creating durable paver blocks and paving elements. Portland cement provides a solid foundation for paving concrete molds, ensuring that the finished products can withstand heavy loads and harsh weather conditions.

High-Strength Cement: For applications requiring enhanced load-bearing capacity and durability, high-strength cement is preferred. This type of cement is often used in paving concrete molds to produce pavers that can endure significant stress and wear, making it suitable for high-traffic areas.

Rapid-Hardening Cement: In projects where time is of the essence, rapid-hardening cement can be used. This type of cement accelerates the curing process, allowing for quicker production and installation of paver blocks. It is particularly useful in commercial and industrial settings where fast turnaround is required.

Blended Cement: Blended cement, which combines Portland cement with supplementary materials like fly ash or slag, is another option for use in paver moulds. This type of cement can enhance the workability and strength of the concrete, while also offering improved environmental sustainability.

Benefits of Using the Right Cement in Paver Moulds

Enhanced Durability: The right type of cement ensures that the pavers produced are resistant to weathering, abrasion, and heavy loads, leading to a longer lifespan and lower maintenance costs.

Improved Aesthetics: Using quality cement contributes to the consistency and appearance of the finished paver blocks, resulting in a more attractive and uniform surface.

효율적인 생산: Selecting the appropriate cement type can streamline the production process, optimizing curing times and reducing overall production costs.

What are the design principles of paving concrete moulds?

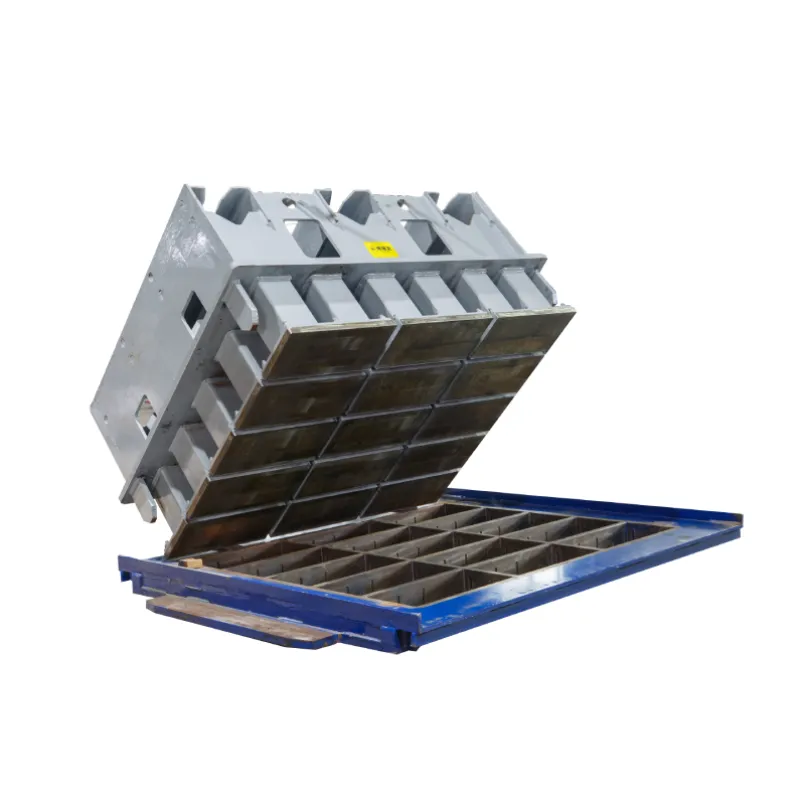

The design principles of paving concrete moulds are crucial for ensuring the production of high-quality, durable, and aesthetically pleasing paver molds. Here are the key design principles:

Precision and Accuracy:

The moulds must be designed with high precision to ensure uniformity in size, shape, and texture of the pavers. Accurate dimensions are essential for the pavers to fit together seamlessly during installation.

Material Selection:

The material used for the moulds should be durable, non-reactive, and capable of withstanding the rigors of repeated use. Common materials include high-grade plastic, rubber, and steel, each chosen based on the specific requirements of the paver design and production process.

Ease of Demoulding:

The moulds should be designed to allow easy removal of the pavers without damaging their edges or surface. Features like tapered edges, smooth interiors, and flexible materials help in reducing sticking and facilitate effortless demoulding.

Surface Texture and Finish:

The interior surface of the moulds should be crafted to produce the desired texture on the paver’s surface, whether it’s smooth, embossed, or patterned. The design should ensure consistent surface quality across all pavers.

Structural Integrity:

The design of the mould must ensure it can withstand the pressure and vibration used during the concrete compaction process. This includes reinforcing areas that might be subjected to the most stress during filling and compaction.

Drainage and Expansion Features:

Moulds should incorporate design elements that accommodate concrete expansion during curing and include features for drainage if required, ensuring the pavers do not crack or deform over time.

These principles guide the design of paving concrete moulds to ensure they meet industry standards and produce pavers that are both functional and visually appealing.