How Hollow Block Moulds Drive Sustainability in Your Production Line

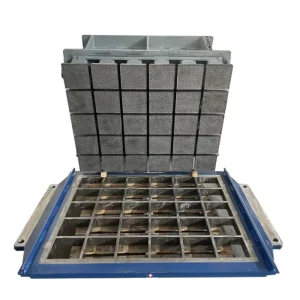

In modern construction, hollow block moulds have become integral to supporting eco-friendly building practices, particularly when designed with sustainability in mind. KBL Machinery provides advanced Block Moulds and Road Brick Moulds that are crafted to reduce both material waste and energy usage, allowing manufacturers to achieve consistent, high-quality output while minimizing their environmental footprint. The precision of KBL’s moulds helps produce uniform block sizes, reducing errors, rework, and resource use for a more sustainable production process.

A standout feature of KBL Machinery's hollow block moulds is their durability, constructed from high-grade materials to endure the demands of large-scale production. This resilience means that fewer replacements are needed over time, translating to less resource consumption and reduced waste. Additionally, KBL’s moulds are customizable, enabling companies to tailor Road Brick Moulds to specific project needs, optimizing production and waste reduction. This durability and adaptability make KBL Machinery a trusted construction equipment supplier for businesses committed to sustainability in their manufacturing practices.

Beyond material efficiency, KBL Machinery’s Block Moulds also support the use of sustainable raw materials. These moulds are compatible with eco-friendly options like recycled aggregates or alternative additives, ensuring quality and structural integrity even when using greener materials. By incorporating KBL’s innovative mould solutions, companies can promote environmentally responsible production practices, meeting both industry and environmental standards.

| Factor | Traditional Moulds | KBL Machinery’s Hollow Block Moulds |

|---|---|---|

| Material Waste | High due to inconsistency | Minimal with precise automation |

| Durability | Prone to frequent replacements | Long-lasting, reducing replacement needs |

| Production Efficiency | Slower, higher resource usage | Faster, optimized material use |

| Eco-Friendliness | Limited eco-friendly compatibility | Supports sustainable and recycled materials |

Block Mould Maintenance: Prolonging Mould Longevity

- Regular Cleaning and Inspection

Keeping hollow block moulds in optimal condition requires routine cleaning after each production cycle. Dust, debris, and excess materials can lead to premature wear if not managed properly. KBL Machinery recommends gentle cleaning and regular inspections to detect any early signs of wear, ensuring prolonged performance. - Lubrication for Moving Parts

For Road Brick Moulds with moving components, proper lubrication is essential to reduce friction and maintain functionality. High-quality lubricants, as advised by KBL Machinery, help prevent wear and extend the life of each mould. - Consistent Temperature Control

Variations in temperature during the moulding process can cause thermal strain on the moulds. KBL Machinery suggests maintaining stable production temperatures to prevent deformation and ensure dimensional stability over time. - Timely Repairs and Part Replacement

Addressing minor wear or damages early on prevents escalation into costly repairs. KBL Machinery provides support for replacing worn parts, helping avoid downtime and ensuring the hollow block mould remains effective. - Controlled Storage Environments

Proper storage is crucial for extending mould lifespan. KBL Machinery recommends storing Block Moulds in controlled, dry spaces to avoid corrosion and degradation, particularly for moulds that aren’t in constant use. - Use of Compatible Raw Materials

Raw material selection impacts mould durability. KBL Machinery advises using materials that are compatible with the mould’s specifications, ensuring optimal performance and reduced wear.

About KBL Machinery

KBL Machinery is an established construction equipment supplier, providing a broad range of solutions such as hollow block moulds, Road Brick Moulds, and other critical equipment. With a dedication to quality and durability, KBL Machinery offers advanced, customizable mould solutions that enhance production efficiency and sustainability in construction.