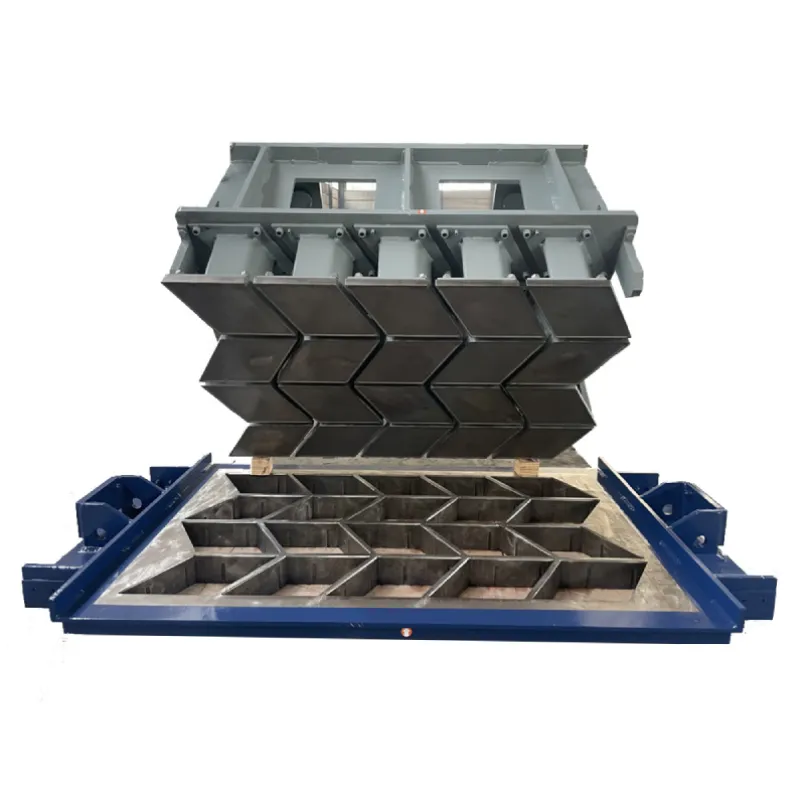

Enhancing Product Quality with Cutting-Edge Concrete Hollow Block Molds

Enhancing product quality in concrete block manufacturing has become increasingly achievable with cutting-edge concrete hollow block molds. These molds, designed with advanced automation systems, ensure precision at every stage of production, from mixing raw materials to the final shaping and curing of concrete blocks. This technology minimizes human error, enabling manufacturers to produce uniform, high-quality blocks that meet strict industry standards. By automating essential processes like material dosing and molding, manufacturers can achieve exact specifications, leading to concrete blocks with superior structural integrity and durability—key components for the construction industry.

One of the key advantages of using concrete hollow block molds is the ability to precisely control the composition and density of the blocks. With integrated control systems, these molds can regulate the pressure during the shaping process, ensuring each block has a uniform density. This directly enhances the strength and resistance of the blocks to wear and environmental factors. Moreover, innovations in heating and drying techniques prevent common issues like cracks and deformations during production, ensuring that the concrete blocks perform well in various environmental conditions, such as extreme temperatures or moisture exposure.

Furthermore, advanced concrete hollow block molds support the use of eco-friendly materials, enabling manufacturers to produce sustainable blocks without sacrificing quality. These molds can accommodate a wider range of raw materials, including recycled components or locally sourced aggregates, reducing environmental impact while maintaining the durability of the blocks. By integrating sustainable practices into high-quality production, manufacturers can meet the growing demand for green construction materials while offering products that stand the test of time.

Brick Making Machine Procurement Guide: Choosing Reliable Suppliers

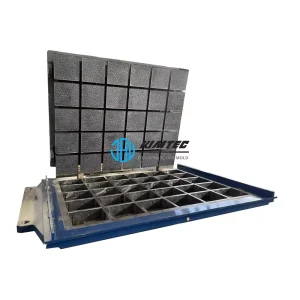

- Supplier Reputation and Experience: When choosing a supplier for brick making equipment, it is essential to evaluate their reputation and experience in the industry. A supplier with a strong track record, such as KBL Machinery, signifies reliability and expertise in delivering high-quality products. An experienced supplier understands the complexities of the manufacturing process and provides tailored technical support and advice. KBL Machinery, as a leading construction equipment supplier, offers a vast range of products, from block moulds to road brick moulds, ensuring that customers have access to the best equipment for their needs.

- Product Range and Customization Options: A good supplier should offer a comprehensive selection of block moulds, including those for hollow blocks, paving stones, and road bricks. KBL Machinery specializes in customizable solutions to meet varying production capacities and levels of automation. Depending on your production goals, whether you require a high output of concrete hollow blocks or specific road brick moulds, a reliable supplier can provide machines that accommodate a variety of materials and customization options. Customization might include features like energy efficiency or automation, which are essential for optimizing production and aligning with your business needs.

- Quality Certifications and Standards: Ensuring that the equipment complies with industry standards is crucial for long-term reliability and safety. KBL Machinery's products, including road brick moulds and concrete hollow block molds, are built to meet international certifications such as ISO and CE. These certifications ensure that the equipment adheres to the highest quality standards, providing peace of mind that the machinery will perform reliably over time. By choosing certified equipment, businesses reduce the risk of downtime, breakdowns, and substandard output.

- After-Sales Support and Service: Effective after-sales support is a key consideration when selecting a supplier. Machines like concrete hollow block molds and block moulds require regular maintenance and occasional repairs, and without reliable service, downtime could disrupt production. KBL Machinery offers comprehensive after-sales support, including operator training, technical assistance, and access to a readily available supply of spare parts. This ensures that any issues with the equipment are resolved quickly, minimizing disruptions in production. As a trusted construction equipment supplier, KBL Machinery's commitment to ongoing support is one of the reasons businesses continue to choose them as their preferred partner.

- Client Reviews and Testimonials: To gauge the quality and reliability of a supplier, it is helpful to read customer reviews and testimonials. Positive feedback from previous clients provides insights into the supplier's service, product quality, and overall experience. KBL Machinery has consistently received favorable reviews for its block moulds, road brick moulds, and concrete hollow block molds. Clients appreciate KBL’s commitment to quality, customer service, and timely delivery. Reaching out to existing customers for feedback is an excellent way to determine whether a supplier can meet your business’s needs and provide long-term value.

Why Choose KBL Machinery

KBL Machinery stands out as a top construction equipment supplier, offering high-performance, reliable, and innovative solutions for the brick and block manufacturing industry. Specializing in concrete hollow block molds, block moulds, and road brick moulds, KBL Machinery provides equipment designed for energy efficiency, sustainability, and precision. Whether you need high-output block moulds for large-scale operations or custom road brick moulds for specialized projects, KBL Machinery offers the ideal solution.

In addition to cutting-edge technology, KBL Machinery provides exceptional after-sales support, ensuring that all customers receive comprehensive training, maintenance, and quick access to spare parts. With a reputation for high-quality products and a commitment to customer satisfaction, KBL Machinery is a trusted partner for businesses aiming to enhance their manufacturing efficiency and product quality.

Key Features of KBL Machinery’s Moulds

| Feature | Concrete Hollow Block Molds | Block Moulds | Road Brick Moulds |

|---|---|---|---|

| Automation | Fully automated options | Customizable automation levels | High-precision automated designs |

| Energy Efficiency | Low energy consumption | Optimized for energy savings | Energy-efficient design |

| Customization | Handles various block sizes | Tailored to specific needs | Can accommodate specialized designs |

| Material Compatibility | Suitable for recycled materials | Adaptable for different raw materials | Ideal for durable road materials |

| Durability | Robust construction | Built for heavy-duty use | Long-lasting for road applications |

| Production Capacity | High-volume output | Scalable production solutions | Perfect for large infrastructure projects |