Concrete Brick Mould Machines: Essential for Efficient Production in Modern Construction

Concrete brick mould machines have become indispensable in today’s construction industry, revolutionizing the way building materials are produced. KBL Machinery is a leading construction equipment supplier that provides advanced concrete brick mould machines, designed to streamline production processes from material mixing to final curing. With automated technology, KBL Machinery’s machines minimize manual labor and maximize output, enabling construction companies to meet the growing demand for high-quality bricks without sacrificing efficiency or precision.

A key advantage of KBL Machinery’s concrete brick mould machines is the integration of innovative technology, allowing for exact control over every aspect of production. This ensures each brick is uniform in size, shape, and strength, which is crucial for maintaining the structural integrity required in modern construction projects. By optimizing material usage and reducing waste, KBL Machinery’s machines enhance productivity while supporting sustainable building practices, making them an ideal choice for environmentally conscious businesses.

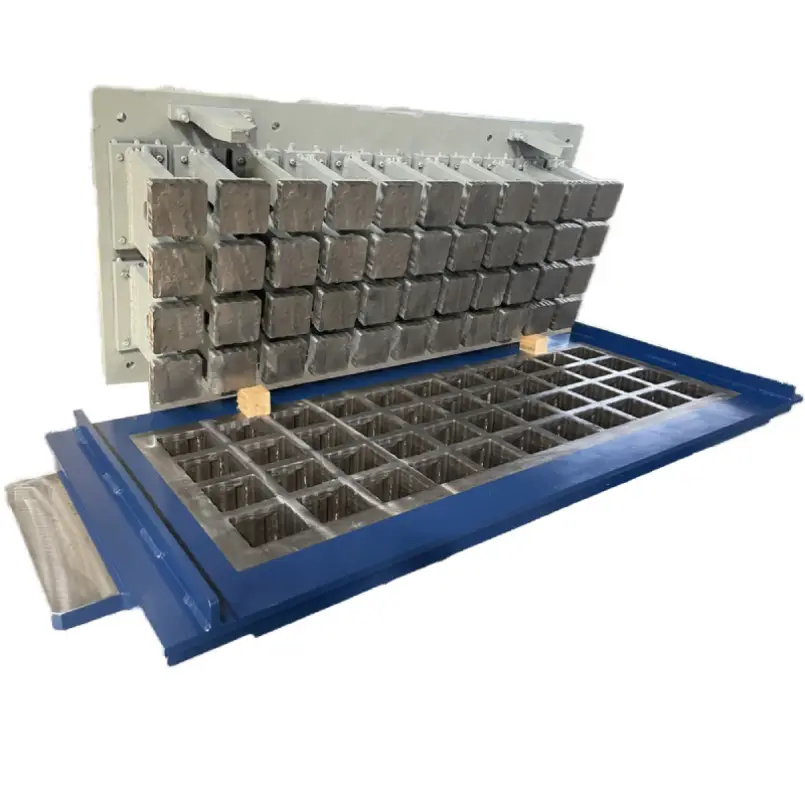

As construction needs continue to grow and diversify, KBL Machinery remains committed to innovation, developing machines that not only improve efficiency but also adapt to a range of production needs. From small-scale sites to large industrial projects, KBL Machinery offers tailored solutions that include Block Moulds and Road Brick Moulds to meet specific requirements. Investing in KBL Machinery’s state-of-the-art concrete brick mould machines provides construction companies with improved productivity, reduced costs, and the assurance of high-quality products.

Advantages of Using Concrete Brick Mould Machines by KBL Machinery

- Labor Efficiency: KBL Machinery’s concrete brick mould machines automate significant parts of the production process, reducing the need for extensive manual labor and lowering labor costs.

- Material Optimization: Designed to maximize the use of raw materials, KBL Machinery’s machines ensure minimal waste, cutting material costs and enhancing overall production efficiency.

- Energy Efficiency: With energy-saving features, KBL Machinery’s concrete brick mould machines consume less power, leading to reduced operational costs and aligning with sustainable building practices.

- Durability and Reduced Maintenance: Built to last, KBL Machinery’s machines, including Block Moulds and Road Brick Moulds, require minimal maintenance, helping businesses avoid frequent repairs and downtime.

- High Production Capacity: These machines are capable of producing large volumes of bricks in shorter time frames, which aids in meeting project deadlines and lowering associated costs.

About KBL Machinery: Leading Construction Equipment Supplier

As a prominent construction equipment supplier, KBL Machinery specializes in producing high-performance concrete brick mould machines as well as Block Moulds and Road Brick Moulds for diverse construction needs. With a focus on advanced technology, durability, and sustainability, KBL Machinery’s machines optimize production, ensuring reliable quality. Known for exceptional customer service, KBL Machinery provides tailored solutions, support, and maintenance, empowering clients to achieve long-term success.

| Key Advantage | Description |

|---|---|

| Labor Efficiency | Reduces manual labor with automated processes, saving on labor costs and increasing production speed. |

| Material Optimization | Maximizes material use, reducing waste and cutting overall material costs. |

| Energy Efficiency | Energy-saving components help reduce electricity consumption, supporting sustainable practices and cutting operational expenses. |

| Durability and Low Maintenance | High-quality construction ensures longevity and reduces maintenance needs, lowering repair costs over time. |

| High Production Capacity | Produces large quantities of bricks in a shorter time, helping companies meet project timelines and reduce associated costs. |