High-Capacity Cement Brick Mold Machines: Ensuring Productivity for Large-Scale Projects

High-capacity cement brick mold machines have become indispensable for large-scale construction projects where reliability and efficiency are crucial. KBL Machinery’s advanced machines are designed to handle significant volumes of raw materials and produce a large number of bricks in each cycle, making them ideal for operations that require high output in a short timeframe. Equipped with automated systems and precision controls, these machines can run continuously with minimal downtime, ensuring manufacturers can meet tight deadlines and maintain a steady supply of quality bricks. This consistency is essential in large projects, helping prevent delays and ensuring construction timelines are met.

A primary advantage of high-capacity cement brick mold machines is their ability to streamline production and reduce bottlenecks, enhancing operational efficiency. KBL Machinery’s machines integrate automation for tasks like material mixing, molding, and curing, making production faster and more accurate than traditional methods. With features like automated batching and real-time monitoring, these machines can optimize output while minimizing waste. This efficiency translates into lower operational costs, making these machines a valuable investment for manufacturers aiming to boost their production capabilities.

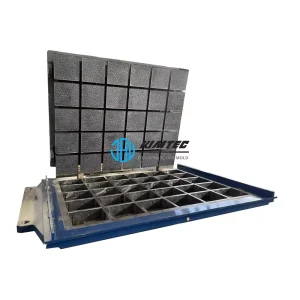

In addition to high productivity, these machines offer flexibility, enabling manufacturers to adapt to diverse project needs. KBL Machinery’s equipment can be programmed to produce various brick types, including Road Brick Moulds and custom-designed blocks, catering to unique project requirements. This versatility allows manufacturers to expand their service offerings, from large infrastructure projects to customized architectural work. By investing in KBL Machinery’s high-capacity cement brick mold machines, manufacturers not only increase their production capabilities but also enhance their adaptability, ensuring long-term success in a competitive market.

Long-Term ROI of Investing in Cement Brick Mold Machines: Key Benefits

- Reduced Labor Costs: One of the immediate benefits of KBL Machinery’s advanced machines is a significant reduction in labor costs. With automation handling most production tasks, from raw material mixing to molding and curing, the need for manual labor is greatly reduced. This not only lowers direct wage expenses but also cuts costs related to workforce management, training, and potential human errors, making the machines a cost-effective choice over time.

- Increased Production Efficiency: KBL Machinery’s cement brick mold machines are designed for fast, efficient production, allowing businesses to fulfill higher demand without additional operational hours. These machines can operate continuously, with minimal downtime, maximizing productivity and enabling businesses to reduce lead times and handle larger projects.

- Energy Savings: KBL’s machines come equipped with energy-efficient technologies, such as optimized motors and intelligent power management. These features significantly reduce power consumption, helping manufacturers lower their utility bills while also supporting sustainable practices—a key industry priority. Long-term energy savings contribute directly to higher ROI.

- Consistent Product Quality: A major advantage of KBL Machinery’s machines is their ability to produce bricks with uniform size, shape, and strength. Automated precision reduces variability, ensuring each brick meets exact specifications and minimizing waste. High product quality enhances brand reputation and builds stronger customer relationships, driving sustained growth.

- Longer Equipment Lifespan: Built with high-quality materials, KBL Machinery’s brick-making machines are durable and designed to handle continuous production. Advanced self-diagnostic features monitor machine health, enabling preventive maintenance and reducing the need for frequent repairs. This durability helps extend the equipment’s lifespan, providing a solid return on the initial investment.

About KBL Machinery: Your Reliable Construction Equipment Supplier

As a top construction equipment supplier, KBL Machinery is dedicated to providing advanced, high-performance solutions for the construction industry. Specializing in cement brick mold machines, Block Moulds, and Road Brick Moulds, KBL Machinery focuses on energy efficiency, durability, and customer satisfaction. Their machines are designed to streamline production, reduce costs, and meet a variety of project needs. KBL Machinery also stands out for its exceptional after-sales support, offering training, technical assistance, and spare parts to ensure long-term success for clients. Partnering with KBL Machinery means working with an experienced construction equipment supplier committed to helping clients thrive in a competitive market.

| Key Benefit | Description |

|---|---|

| Reduced Labor Costs | Automation reduces the need for manual labor, cutting wage expenses and workforce management costs. |

| Increased Production Efficiency | High-speed, continuous production capabilities allow businesses to fulfill large orders efficiently. |

| Energy Savings | Energy-efficient features reduce power consumption, cutting utility bills and supporting sustainability. |

| Consistent Product Quality | Precision automation ensures uniform size, shape, and strength in bricks, minimizing waste and enhancing reputation. |

| Longer Equipment Lifespan | Durable construction and self-diagnostics extend the equipment’s lifespan, reducing the frequency of costly repairs. |