Why Investing in a Quality 8x8x16 Concrete Block Mold Pays Off

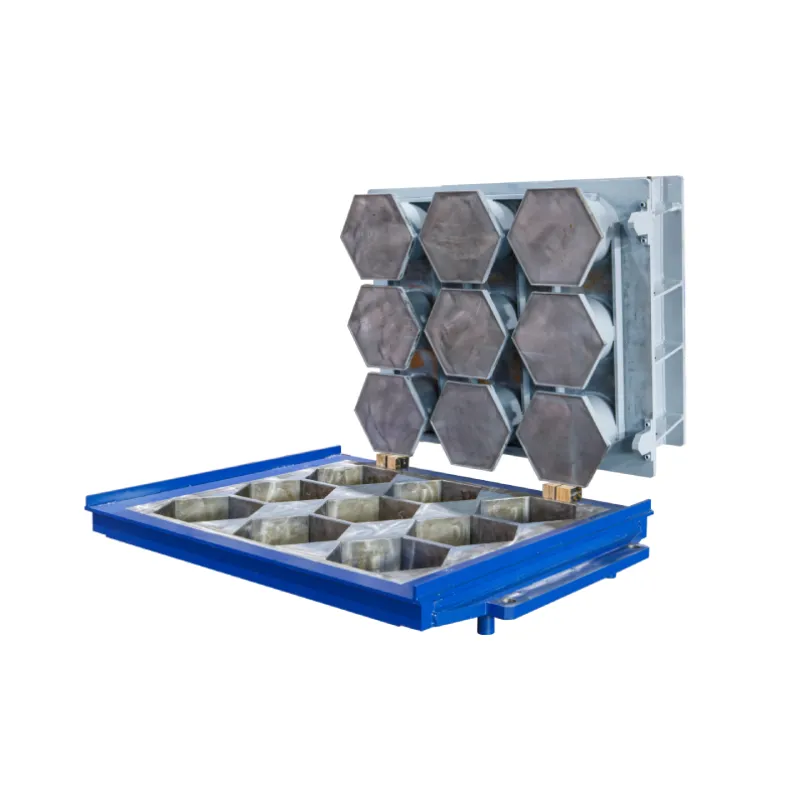

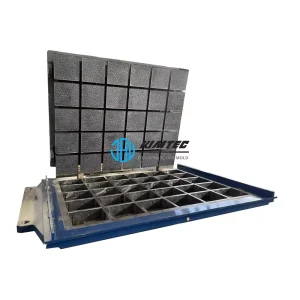

Investing in a high-quality 8x8x16 concrete block mold, such as those provided by KBL Machinery, offers substantial long-term benefits for construction businesses. A durable and precise 8x8x16 concrete block mold ensures the consistent production of strong blocks, reducing defects and minimizing wastage.

With state-of-the-art engineering, KBL Machinery’s molds deliver superior performance, allowing companies to meet high demand without compromising on block quality. This consistency enhances operational efficiency and builds a strong market reputation for reliability.

In addition to boosting productivity, a quality 8x8x16 concrete block mold from KBL Machinery is designed for enhanced energy efficiency, leading to lower operational costs. These molds integrate advanced automation and hydraulic technology, reducing energy consumption while maintaining peak performance. This eco-friendly approach aligns with modern sustainability goals and minimizes expenses related to energy use over time. By optimizing material usage and minimizing the need for manual labor, businesses can achieve significant cost savings.

Furthermore, the durability and reliability of KBL Machinery’s 8x8x16 concrete block molds mean less frequent maintenance and minimal downtime. Built for heavy industrial use, these molds ensure continuous operation and reduce the risk of costly interruptions. Investing in a well-engineered mold from KBL Machinery translates into lower maintenance costs and increased profitability. Choosing KBL Machinery’s molds guarantees competitiveness in a demanding market while benefiting from excellent service and support.

Brick Making Machine Maintenance: Tips for Longevity and Efficiency

- Regular Cleaning: Keeping your brick-making machine clean is crucial for peak performance. KBL Machinery recommends routine cleaning to prevent material buildup that can cause blockages and reduce efficiency.

- Lubrication of Moving Parts: Proper lubrication of moving parts is essential for smooth operation. KBL Machinery advises using quality lubricants and following a maintenance schedule to minimize wear and tear.

- Inspection of Hydraulic Systems: For machines with hydraulic systems, such as those from KBL Machinery, regularly check for leaks and ensure the system maintains proper pressure. This helps prevent malfunctions and extends machine life.

- Routine Component Check: Regular inspections of components like Block Moulds, belts, and bearings help detect wear or damage early. KBL Machinery recommends timely replacement of worn-out parts to avoid costly repairs.

- Proper Storage and Protection: When not in use, store your KBL Machinery brick-making machine in a clean, dry area to protect it from harsh weather conditions, which helps extend its service life.

About Us

KBL Machinery is a trusted construction equipment supplier known for its high-quality 8x8x16 concrete block molds, Block Moulds, and Road Brick Moulds. We are dedicated to providing advanced technology, efficiency, and sustainability, offering machines and molds designed to meet the evolving needs of the construction industry. Our products are engineered for precision, durability, and eco-friendly production, ensuring that clients achieve superior results while minimizing their environmental footprint. At KBL Machinery, we pride ourselves on excellent customer service, supporting businesses worldwide with top-quality machinery and industry expertise.

| Maintenance Aspect | Description |

|---|---|

| Regular Cleaning | Routine cleaning prevents material buildup, ensuring optimal performance and preventing blockages. |

| Lubrication of Moving Parts | Scheduled lubrication reduces wear and tear, ensuring smooth operation and prolonging part life. |

| Hydraulic System Checks | Regularly checking for leaks and maintaining pressure optimizes performance and extends lifespan. |

| Routine Component Inspection | Inspecting Block Moulds, belts, and bearings helps detect early signs of wear, minimizing costly breakdowns. |

| Proper Storage | Storing machines in a dry, clean environment protects them from weather-related damage, extending their functionality and service life. |