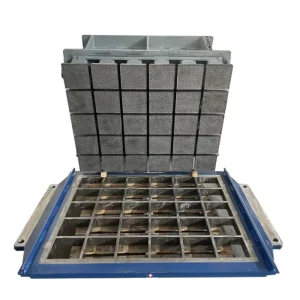

China concrete block mold suppliers

At KBL Machinery, our concrete block molds are engineered for precision and durability, ensuring consistent block production with minimal waste. These molds are perfect for large-scale projects, delivering efficiency and long-term reliability for your construction needs.

どのように Concrete Block Mold Technology Can Drive Sustainability in Your Production Line

Concrete block mold technology plays a pivotal role in modern construction, especially for businesses aiming to implement sustainable production practices. KBL機械をリードしている。 建設機械サプライヤー, offers advanced コンクリートブロック型 solutions that significantly reduce material waste and energy consumption. By utilizing high-precision moulds, companies can achieve uniform block sizes, minimizing errors and reducing rework. This efficiency not only improves the production process but also lowers the environmental footprint, promoting more sustainable construction practices.

Durability is another key advantage of KBL機械's コンクリートブロック型 technology. These moulds are built from high-grade materials to withstand the rigorous demands of heavy-duty production. Fewer replacements are needed, which not only reduces costs but also decreases the environmental impact associated with producing and transporting new moulds. Additionally, KBL機械 offers customizable solutions that allow manufacturers to adapt moulds for specific projects, further increasing production efficiency and minimizing material waste.

Incorporating 道路用レンガ型 そして ブロックモールド into your production line can also enhance sustainability by enabling the use of eco-friendly and recycled materials. KBL機械's innovative moulds maintain the structural integrity of blocks, even when using alternative materials like recycled aggregates. By integrating these advanced moulds into your operations, you can meet both environmental and industry standards while ensuring high-quality output.

Maintenance Practices for Extending the Lifespan of Your Concrete Block Mold

Proper maintenance of your コンクリートブロック型 is essential for prolonging its lifespan and maintaining production efficiency. KBL機械 recommends several key practices to ensure your moulds continue to perform at their best.

| Maintenance Task | Importance | Recommended Action by KBL Machinery |

|---|---|---|

| Regular Cleaning and Inspection | Prevents dirt and debris buildup that can cause wear | Use non-abrasive tools and conduct frequent inspections |

| 可動部品の潤滑 | Reduces friction and unnecessary wear | Select high-quality lubricants suitable for your mould materials |

| Consistent Temperature Control | Prevents mould deformation due to thermal expansion | Implement temperature controls to maintain dimensional stability |

| Timely Repairs and Part Replacement | Avoids larger issues that could halt production | Replace worn parts, like inserts or plates, before damage escalates |

| Storage in Controlled Environments | Prevents rust and corrosion during periods of non-use | Store moulds in dry, controlled spaces with protective coverings |

| Using Compatible Raw Materials | Ensures mould durability and optimal performance | Choose raw materials that match the mould specifications |

By following these practices, you can ensure your コンクリートブロック型 continues to operate efficiently, supporting long-term success and reducing costs. KBL機械 provides comprehensive maintenance support to help businesses avoid costly downtime and keep production lines running smoothly.

About KBL機械

KBL機械 is a trusted 建設機械サプライヤー known for manufacturing high-quality ブロックモールド, 道路用レンガ型そして concrete block molds. With a commitment to innovation, the company delivers solutions that enhance efficiency and productivity in the construction industry. KBL機械's products meet international standards and are designed to suit the unique needs of each business, offering customizability and long-term durability. Supported by a professional engineering team and dedicated customer service, KBL機械 is focused on providing reliable and sustainable equipment for the global market.

Incorporating KBL機械's advanced mould technologies into your operations not only drives sustainability but also positions your business to meet the growing demands of the modern construction landscape.