How to Use Block Molds?

4月 11, 2025

Efficiency and quality are two of the most important factors in the construction industry. Block moulds have proven to be very useful in achieving both goals. Today’s article is not only intended to provide you with guidance, but also to give you an understanding of the process of concrete block production and why you should do it.

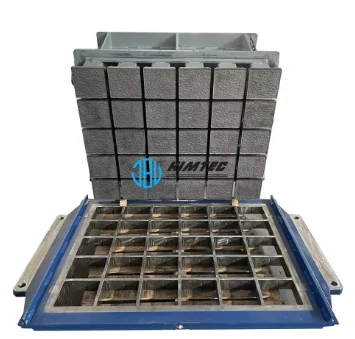

Definition of Block Moulds

Block moulds have been and still are a major component of the entire concrete block production process. They enable factories to produce various types of blocks such as solid blocks, hollow blocks, interlocking blocks, and permeable blocks. If you choose the right block mold, you can customize the size, shape, and design of concrete blocks for your project.

Block Mould Categories

Solid Block Moulds: They can produce super-strong concrete blocks suitable for structural applications.

Hollow Block Moulds: They are best suited for building lightweight buildings because they have thermal insulation properties and reduce material costs.

Interlocking Block Moulds: This type of mold creates joints that are very similar to bricks, making it ideal for various pavement and wall tiles.

Curbstone block moulds: They are used to produce curbstones, which contribute to greening and thus promote the improvement of urban pavement.

Permeable pavement moulds: These molds have sufficient production and are the most permeable moulds, which are very suitable for environmental protection projects.

Advantages of using block moulds?

1. Versatility of manufacturing process

One of the main advantages of using block molds is the ease of operation. Manufacturers can quickly move from one mould to another, thereby designing a variety of blocks without using separate machines. A good example is switching between grass stone molds and curbstone moulds. By switching from one mould to another, you can meet various construction needs in a short time. This versatility can maximize the use of equipment and simplify the construction process.

2. Customization and precision

The replaceable design of block moulds enables full control of the production process. If block moulds are used to produce standard or special blocks, the precision of the mould will be reflected in the stability and durability of the final product.

3. Cost-effectiveness

Our company’s block moulds have made a great contribution to reducing production costs. High-quality moulds can be used for a long time. Therefore, you can produce blocks in large quantities without sacrificing quality.

4. Meet Diverse Project Needs

The construction industry often faces a variety of project needs. Block moulds allow producers to respond quickly to new needs. Whether it is a residential, commercial or transportation project, having a variety of moulds to choose from allows you to respond quickly to needs and minimize waste.

How to use block moulds effectively?

Step 1: Choose the most suitable mould

It is crucial to choose the right block mould to meet your needs. Factors such as block type, size and design are worth considering. Kimberly Block Machinery offers a wide variety of molds to ensure that you can find the right mold to meet your needs.

Step 2: Gather materials

Gather the materials required for concrete block production. In addition, make sure that the concrete mix is good quality, necessary additives, and any other materials related to your block type.

Step 3: Mold setup

Prepare the mold according to the manufacturer’s instructions. In addition, make sure that the mold is clean and there are no obstructions inside, otherwise it may result in an imperfect final product.

Step 4: Pour cement

Carefully remove the mold and pour the concrete evenly into the mold. Make sure that the concrete does not overflow during the filling process and that the block retains its original shape.

Step 5: Vibration Pressurization

Pour the concrete into the mold and then use a compactor to vibrate the concrete. This is essential to seal the voids and obtain high strength of the block.

Step 6: Remove the mold

After the block cools, remove it from the mold and inspect each part.

Conclusion

Utilizing block moulds can revolutionize your concrete block production process. Their versatility, customization options, and cost-effectiveness make them an essential investment for any construction project. At Kimberly Block Machinery, we pride ourselves on providing high-quality block moulds for sale that meet the diverse needs of the construction industry. By incorporating our moulds into your production line, you can boost productivity and ensure consistent quality in every block you produce.

Explore our range of block moulds today and discover how they can enhance your construction projects!