Innovative Machines for Concrete Block Casting

In the rapidly advancing construction industry, concrete block casting has emerged as a cornerstone of efficient and precise building material production. KBL Machinery leads the way with state-of-the-art machines specifically designed for seamless block casting operations. These machines streamline every step of the production process, from mixing raw materials to forming and curing, enabling businesses to produce high-quality blocks quickly and efficiently. By reducing manual intervention through advanced automation, KBL Machinery’s machines ensure consistency and productivity, meeting the demands of modern construction projects with ease.

What distinguishes KBL Machinery’s concrete block casting solutions is the integration of innovative technology, allowing for precise control over production parameters. This guarantees uniformity in block size, shape, and strength, essential for the structural integrity of construction projects. Furthermore, by optimizing raw material use and minimizing waste, these machines support sustainable construction practices, making them a perfect fit for environmentally conscious businesses.

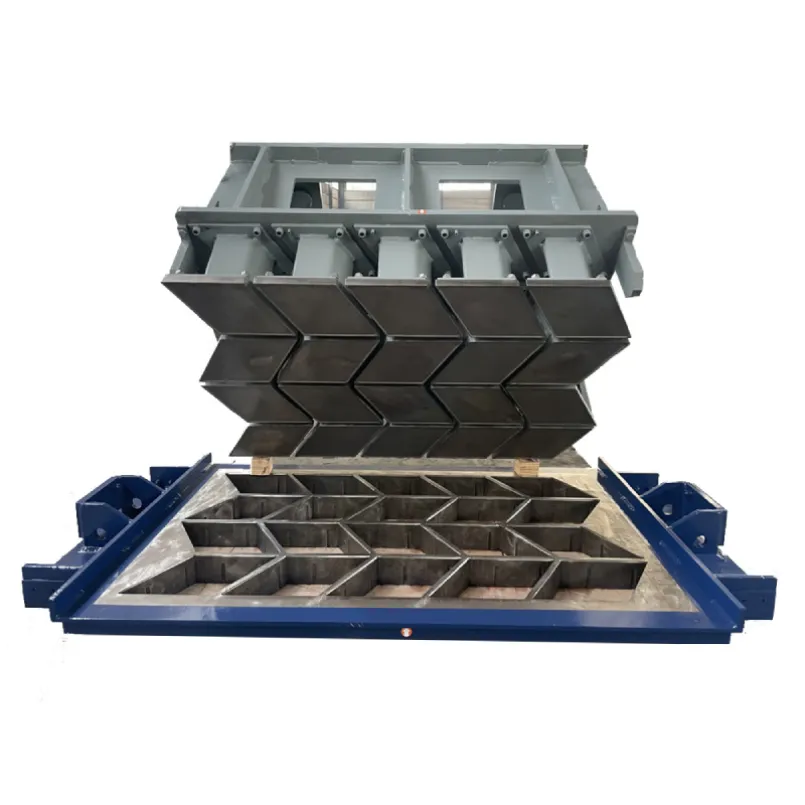

As construction needs evolve, KBL Machinery continues to innovate, offering machines adaptable to a variety of applications. From ブロックモールド for diverse brick designs to specialized Road Brick Moulds, KBL Machinery ensures every product aligns with industry standards. Whether for small-scale operations or industrial projects, KBL Machinery delivers tailored solutions that enhance efficiency, lower costs, and meet the highest quality benchmarks.

How Block Making Machines Are Revolutionizing Construction Costs

- 労働効率: KBL Machinery’s block making machines automate the complex processes of concrete block casting, reducing reliance on manual labor and significantly lowering labor expenses.

- 素材の最適化: These machines are designed to make the most of raw materials, ensuring minimal waste and maximizing cost-effectiveness. This capability is especially useful for projects requiring precise blocks, including those using Block Moulds or 道路用レンガ型.

- エネルギー効率: Equipped with energy-saving technologies, KBL Machinery’s machines consume less electricity while maintaining high output. This reduces operational costs and supports sustainable practices.

- Durability and Low Maintenance: Built with robust materials, KBL Machinery’s block making machines ensure longevity and reliability, cutting down on maintenance needs and repair expenses.

- 高出力: With the ability to produce large quantities of blocks in a shorter time, KBL Machinery’s machines help construction companies meet deadlines efficiently, minimizing delays and related costs.

KBL機械について

As a globally recognized 建設機械サプライヤー, KBL Machinery specializes in designing and manufacturing advanced machines for concrete block casting, Block Moulds, and Road Brick Moulds. Renowned for their durability, precision, and efficiency, KBL Machinery’s solutions empower businesses to streamline production processes while meeting stringent quality and sustainability standards.

At KBL Machinery, we are committed to providing exceptional customer support and tailored solutions. From initial consultation to post-sale services, we ensure our clients have the tools and expertise needed for long-term success. With cutting-edge technology and a dedication to innovation, KBL Machinery continues to be the trusted partner for businesses worldwide.

| 特徴 | ベネフィット |

|---|---|

| Precision Engineering | Ensures consistent quality for concrete block casting and other products |

| Energy-Efficient Design | Lowers electricity costs while supporting eco-friendly practices |

| Automation Capabilities | Reduces reliance on manual labor and improves production speed |

| 耐久性 | Robust construction ensures long-term performance and reduced maintenance needs |

| 多彩なアプリケーション | Integrates seamlessly with ブロックモールド そして 道路用レンガ型 for diverse uses |

KBL Machinery continues to redefine the standards of concrete block casting, offering innovative, sustainable, and cost-effective solutions to meet the growing demands of the construction industry.