製品カテゴリー

Integrated Arrow Baling Machine

This machine is a component of the fully automatic plastic strapping machine system, with the packaging function of the module system. It is equipped with a moving track that runs smoothly and has precise positioning. It can automatically repeat the feeding of straps, as fast as 1 strapping every 20 seconds, greatly improving production efficiency. It can also automatically change and feed straps, thread straps at any height, and the tension coefficient can be adjusted. The adjustment is simple and accurate to ensure the strapping effect.

Main Technical Data:

| Model | Integrated arrow baling machine |

|---|---|

| Total power (kw) | 3KW |

| Machine size by mm (length×width×height) |

2100*2100*4300 |

| Total weight (kg) | 1000KG |

Arrow-Piercing Cart

This machine is equipped with a purely mechanical turntable for belt storage, a freely retractable belt threading slot, and an integrated arrow-threading baler that is synchronously driven, with a storage capacity of up to 70KG plastic-steel belts.

This machine is equipped with a purely mechanical turntable for belt storage, a freely retractable belt threading slot, and an integrated arrow-threading baler that is synchronously driven, with a storage capacity of up to 70KG plastic-steel belts.

Main Technical Data :

| Model | Arrow-piercing cart |

|---|---|

| Machine size by mm (length×width×height) |

1300*500*2100 |

| Total weight (kg) | 160KG |

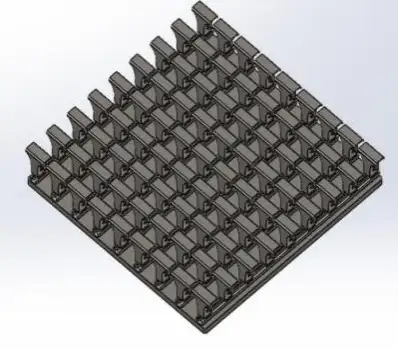

Arrow Tray

Arrow try is used to place brick stack for easy bundling,packaging and transportation.

Main Technical Data:

| Model | Arrow tray |

|---|---|

| Machine size by mm (length×width×height) |

1200*1200*140 |

| Total weight (kg) | 290KG/1pc |

Arrow Head Combination

| Equipment technical parameters | |||

|---|---|---|---|

| Single bundle time | The arrow slot takes about 20 seconds (including movement) | Move rails | A variety of positioning programs to meet various needs Maximum distance of guide rail movement: 1100mm Guide rail moving speed: about 200mm/s |

| Head tension | Max.3000N | ||

| Welding module weight | 20kg | ||

| Weight of belt feeding/tensioning module | 21kg | Arrow-piercing cart | Separated from the equipment, with belt storage device |

| Interface bonding length | 25mm | Power Requirements | 380V/3ph/50Hz+PE |

| Feeding/tensioning speed | 3m/s | Rated Power | 3.5Kw |

| Head frame moving speed | About 160mm/s | Total machine weight | 1200kgs |

| Buckle making method | Suitable for friction welding of plastic strips | Brick stack height range | 350-1800mm |

| コンベアラインの高さ | コンベアラインの高さ | Brick stack width range | 300-1300mm |

| Strapping belt | |

|---|---|

| PET belt | width:12/16/19MM |

| thickness:0.6 -- 1.0MM | |

| Taper data | Inner dia.:406MM |

| Tape width:150 -- 190MM | |

| Tape weight :20 - 75KG | |

Complete Arrow Baling Machine Pic Showed