How Interlocking Blocks Mould Are Transforming Modern Construction

Nov 7, 2024

Construction methods are constantly evolving for efficiency and sustainability. Interlocking block molds have emerged as a significant innovation, simplifying construction and improving structural integrity.

What Are Interlocking Block Molds?

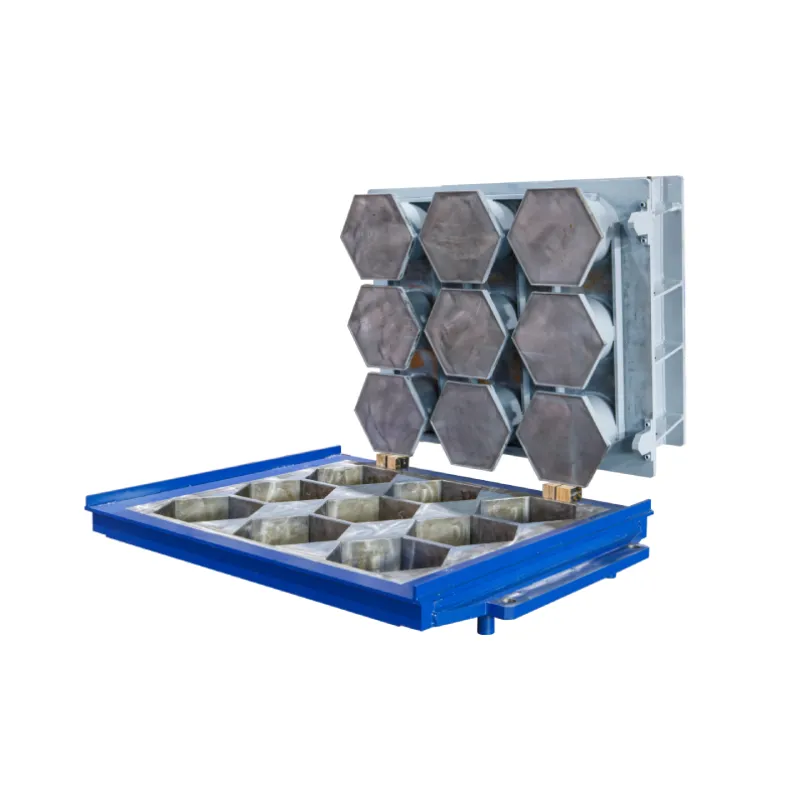

Interlocking block molds are specialized molds used to create blocks that interlock perfectly without the need for traditional mortar. These blocks connect seamlessly, providing stronger, more stable structures. This technology is increasingly popular in modern construction for its practicality and efficiency.

Key Benefits of Using Interlocking Blocks Mould

- Time-Saving: Building with interlocking blocks mould allows for quicker assembly, significantly reducing construction time.

- Reduced Material Costs: The blocks fit tightly, which minimizes the need for additional materials like cement or mortar.

- Eco-Friendly Construction: Many interlocking block molds are made from sustainable or recyclable materials.

- Versatility: The molds are adaptable for various construction needs, such as homes, garden walls, and temporary structures.

- User-Friendly: The system simplifies the construction process, making it accessible for both professionals and DIY enthusiasts.

Understanding Interlock Mold Price

The interlock mold price can vary widely based on factors such as material, design complexity, and size. Prices typically range from a few hundred to several thousand dollars, depending on quality and manufacturer reputation.

Factors Affecting Interlock Mold Price Include:

- Material Quality: Steel molds are more expensive but durable. Plastic molds are cheaper but may not last as long.

- Design Complexity: Intricate designs and customizable molds tend to come at a higher price.

- Size of Mold: Larger molds for bigger blocks will often have a higher cost.

- Manufacturer Reputation: Established manufacturers might charge more, but they ensure quality and reliability.

Choosing the Right Interlocking Blocks Mould

When selecting an interlocking blocks mould, it is essential to balance quality and cost. A mold that is too cheap might lead to structural issues, while high-end molds could strain your budget without significant added value for small projects.

Tips for Choosing Your Interlocking Block Mold

- Identify Project Requirements: Consider the type and size of the blocks needed for your project.

- Research Manufacturer Reliability: Choose manufacturers with a strong track record, like KBL Machinery.

- Evaluate Price vs. Quality: The most affordable option isn’t always the best. Balance price with expected durability and performance.

- Ask for Samples: If possible, test a sample mold or block to see if it meets your expectations.

Why KBL Machinery Is a Top Choice for Interlocking Blocks Mould

KBL Machinery stands out as a trusted manufacturer and supplier of block machinery and molds. The company has a strong reputation for producing high-quality products at competitive prices.

What Sets KBL Machinery Apart:

- High Quality: KBL Machinery molds are known for durability and precision, ensuring each block fits perfectly.

- Affordable Interlock Mold Price: They offer cost-effective solutions without compromising on quality.

- Global Reach and Support: KBL Machinery serves customers worldwide and provides excellent customer service before and after purchase.

- Variety of Options: They have a broad selection of molds, catering to both small-scale DIY projects and large-scale commercial construction.

Conclusion

Interlocking block molds offer numerous advantages for modern construction. They make projects faster, more cost-effective, and environmentally friendly. Understanding the interlock mold price helps in making informed decisions that match project needs and budgets. Trusted manufacturers like KBL Machinery provide a range of high-quality molds that can cater to various requirements. Investing in the right interlocking blocks mould ensures durability, efficiency, and overall project success.