A: Premium special alloy raw material for production.

B: 80000 or 120000 cycle periods are available;

C: following heat treatment, hardness can reach 62 HRC or even 65 HRC.

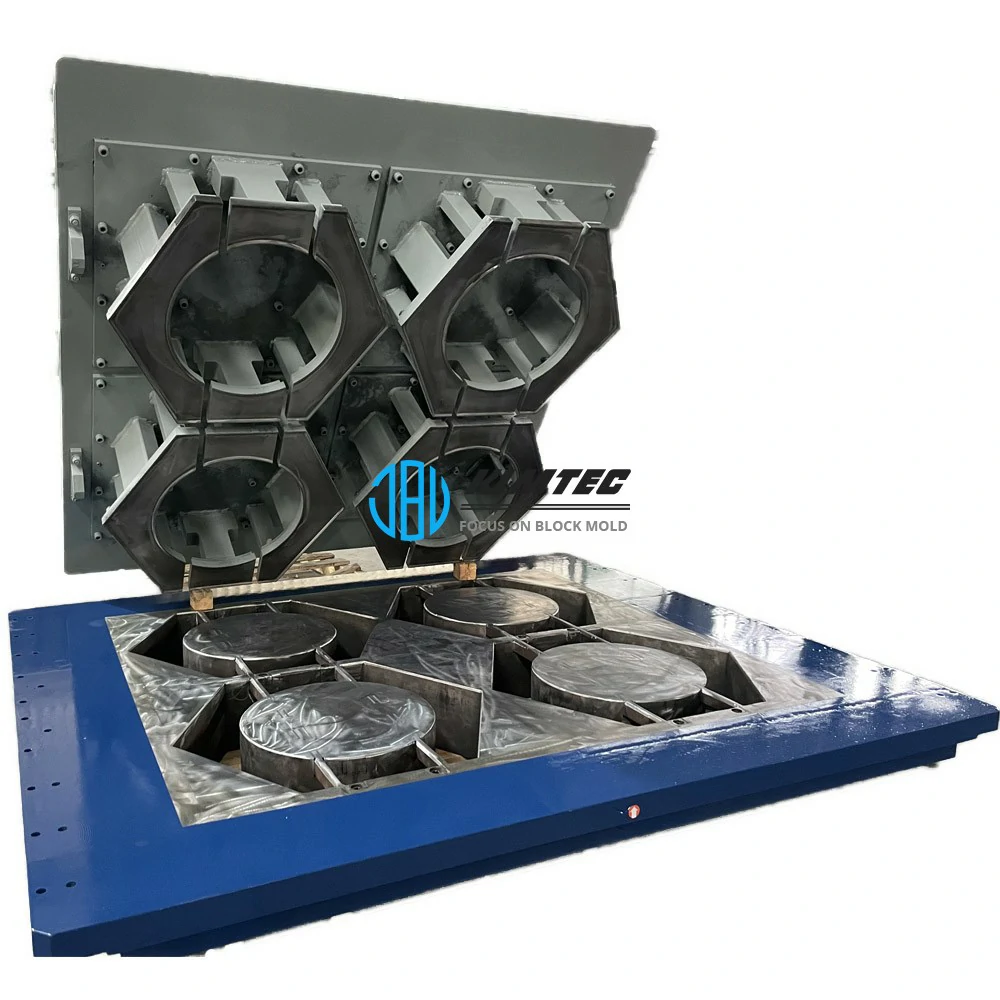

Hourdi parpa moule concrete block mould for block brick making machines :

1. Block Type: We design and manufacture top-quality steel molds for interlocking paving stones, slabs, permeable pavers, curbstones, retaining walls, and hollow or special blocks. Our creations match your needs and include innovative ideas.

2. Raw Material: For our concrete block molds, we use high-end, specially quenched and tempered steel from Italy. This material undergoes heat treatment to enhance its abrasion resistance further.

3. Manufacturing Experience: With nearly 30 years of experience, we serve customers across many countries. We blend our expertise with premium steel to ensure all buyers receive high-quality products. And because we care about excellence, we continuously improve our offerings.

Technical information on our molds:

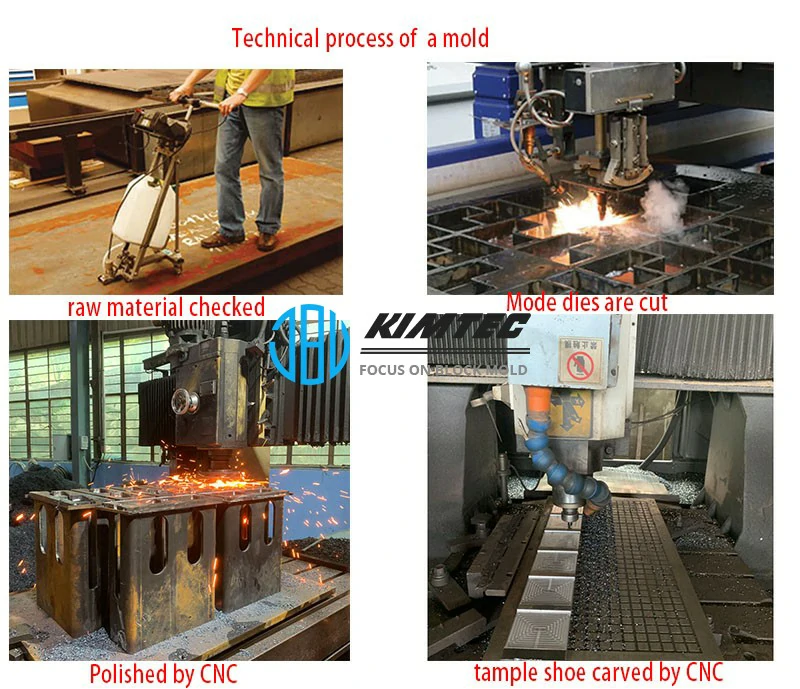

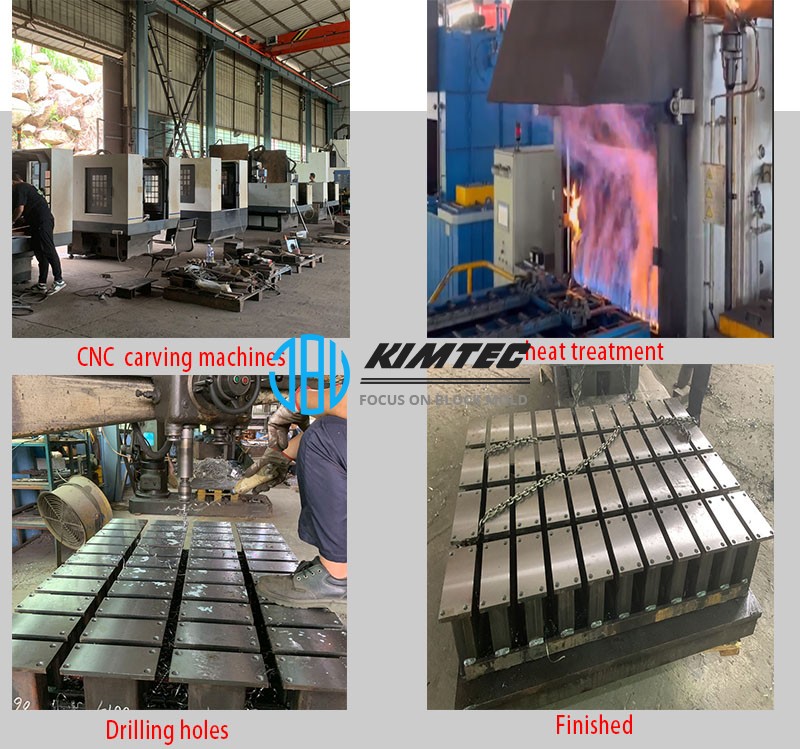

Several production processes revealed:

More different molds showed:

A few completed blocks for reference:

FAQ:

- How can I get a quote?

A. Send us your detailed block drawings, and we'll check them to provide a quote accordingly.

B. Without drawings, inform us of the block type you need, like hollow or solid. Also, send a picture, specifying its size in length, width, and thickness in mm.

C. What are your pallet dimensions?

D. Share the size of your tamper head and the height of your down mold.

E. Tell us how your mold connects to your machine. Providing connection drawings would help.

Once we have your details, we'll prepare your quote quickly.

- What about delivery time?

For standard molds, expect 20-25 workdays after receiving your deposit, and for high-end molds, it's 30-40 workdays.

- How is the transport packing done?

We use wooden crates with plastic film, or we can customize according to your needs.

- Will the new mold fit my machine?

We've made molds for various brands, possibly compatible with yours. You can either measure it yourself or let us do it through photos. This ensures a perfect fit without issues.

- What are the payment terms?

To proceed, we require a 50% advance via T/T, and the balance must be paid before shipment.

- How can I contact you?

Reach out to us on WeChat/WhatsApp: +86-1330506196 or +86-18960287187. Thank you!