The Future of Block Molds: Technology and Automation

The future of block mold manufacturing is rapidly advancing with new developments in technology and automation, and KBL Machinery is leading the charge in these innovations. Modern block molds are becoming smarter, faster, and more efficient through automated systems that reduce the need for manual labor while ensuring precision in quality control. At KBL Machinery, we are integrating AI and machine learning into block mold production, allowing our machines to optimize production cycles, monitor material usage, and predict maintenance needs. These advancements not only increase efficiency but also improve the consistency and durability of the blocks produced.

Automation is also essential in reducing environmental impact, which is a priority for KBL Machinery. By automating block mold production processes, energy consumption is significantly reduced, minimizing the carbon footprint. Furthermore, KBL Machinery has developed machines capable of incorporating recycled materials, such as slag and fly ash, into block mold production, promoting sustainable building practices. As automation continues to evolve, KBL Machinery’s machines offer greater control and customization, allowing manufacturers to meet specific project requirements efficiently and with minimal waste.

In the coming years, the future of block molds will feature higher levels of connectivity and data-driven insights. KBL Machinery is heavily investing in smart technologies, enabling operators to remotely monitor production, access analytics, and make data-informed decisions to optimize operations. As the construction industry embraces more automated and eco-friendly solutions, KBL Machinery is well-positioned to lead this transformation, offering the most advanced, reliable, and sustainable block molds and Moules pour briques de route in the market.

How to Start a Block Manufacturing Business with the Right Machine

- Assess Market Demand: Before investing in a block mold machine, it’s essential to analyze local market demand for different types of blocks. Understanding the demand will guide you in choosing the right machine and block sizes.

- Select the Right Block Making Machine: Choose a machine from KBL Machinery that aligns with your production needs. Consider automation level, production capacity, and versatility in Moules pour blocs to ensure you meet your business objectives.

- Consider Location and Space: Establish your block manufacturing plant in a location with sufficient space for block molds, raw material storage, and block curing. Ensure that the site is accessible for distribution to your target market.

- Secure Funding: Calculate the costs for acquiring a block mold machine, raw materials, labor, and other operational expenses. Develop a financial plan and secure funding through loans, investors, or personal savings to start your business.

- Train Your Workforce: After purchasing a block mold machine from KBL Machinery, invest in training employees to operate it efficiently. Proper training is essential to minimize downtime and ensure smooth production.

À propos de KBL Machinery

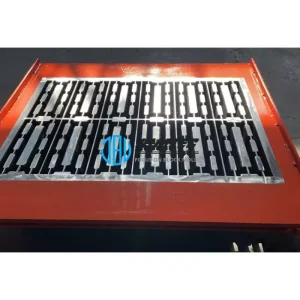

KBL Machinery is a top fournisseur de matériel de construction, providing high-performance Block Moulds and Road Brick Moulds that cater to the evolving needs of the construction industry. We prioritize innovation, quality, and sustainability, offering machines that support both small-scale and large-scale production. Our commitment to technological advancement ensures that every machine delivers optimal performance, energy efficiency, and durability. Businesses worldwide trust KBL Machinery to enhance their production capabilities, making us a reliable partner for those seeking high-quality, sustainable construction equipment.

| Key Feature | Description |

|---|---|

| Automatisation et contrôle | Full automation reduces labor needs, ensures quality, and improves operational efficiency. |

| Efficacité énergétique | Energy-saving technology reduces electricity consumption, supporting eco-friendly construction. |

| Capacité de production élevée | Enables high-volume production for large-scale projects, meeting market demand effectively. |

| Versatility | Provides a range of Moules pour blocs sizes and types to meet various project needs. |

| Durability | Built for long-term use in challenging environments, offering a strong return on investment. |

| Entretien facile | Designed for quick and efficient routine upkeep, reducing downtime. |