Optimizing Production with Advanced Stone Moulds Technology

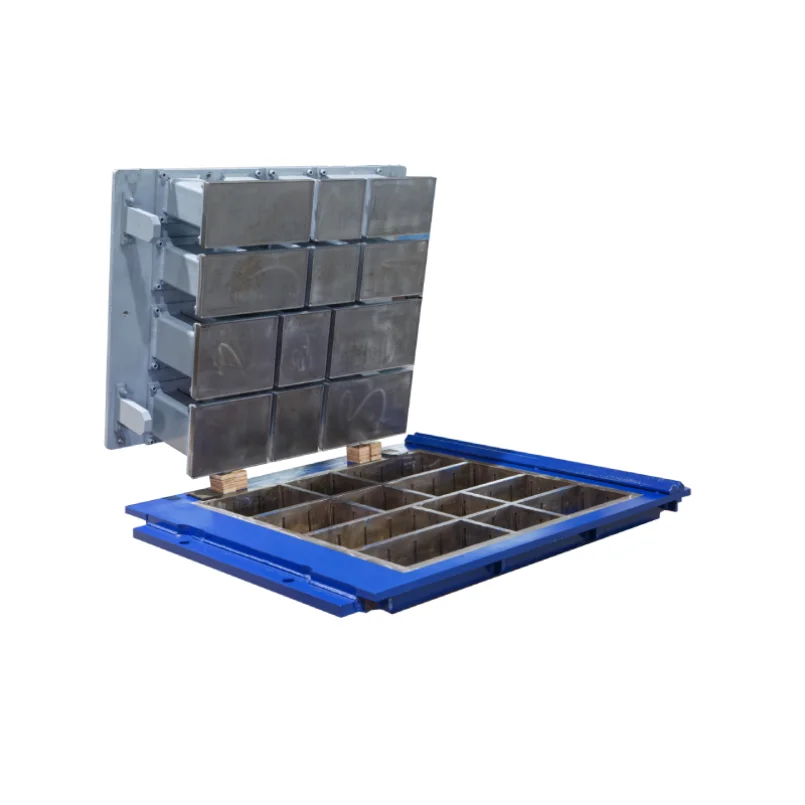

Stone moulds have become a critical component in optimizing brick and block manufacturing processes, providing unmatched precision and versatility. KBL Machinery leads the industry by integrating advanced stone moulds into their state-of-the-art brick making machines, ensuring enhanced efficiency and product quality. These moulds allow manufacturers to produce a wide range of high-quality bricks and stones, from decorative elements to load-bearing blocks, with exceptional accuracy and consistency.

KBL Machinery’s stone moulds are designed to reduce waste and maximize material usage by incorporating intelligent dosing and automated systems. Paired with advanced technology, these moulds enable manufacturers to achieve uniformity in size, shape, and strength while significantly minimizing production time. The compatibility of these moulds with Moules pour blocs and Road Brick Moulds adds further flexibility, allowing businesses to cater to diverse construction needs with ease.

As a trusted construction equipment supplier, KBL Machinery ensures that their machines and moulds meet the evolving demands of the construction industry. By combining energy efficiency with innovative design, their solutions not only enhance productivity but also promote sustainability in manufacturing.

How Advanced Stone Mould Technology Reduces Costs

Automation of Processes:

KBL Machinery’s machines equipped with stone moulds automate key production stages, reducing the reliance on manual labor. This decreases labor costs while boosting output and ensuring consistency.

Efficacité énergétique:

With energy-saving motors and optimized heating systems, these machines reduce power consumption. This not only lowers operational costs but also supports eco-friendly practices, meeting the increasing demand for sustainable solutions.

Minimization of Material Waste:

Intelligent systems ensure precise raw material usage, minimizing waste and reducing overall material costs. This precision enhances the quality of blocks produced using Block Moulds and Moules pour briques de route, ensuring customer satisfaction.

Increased Production Speed:

Advanced machines paired with stone moulds operate continuously, significantly reducing production cycles and allowing businesses to meet tight deadlines without additional costs.

Reduced Maintenance Costs:

Durable designs and self-diagnostic systems help identify potential issues early, reducing downtime and repair expenses. This ensures the long-term reliability of the machinery.

Why Choose KBL Machinery?

En tant que leader fournisseur de matériel de construction, KBL Machinery specializes in providing innovative and durable solutions, including stone moulds, Block Moulds, and Road Brick Moulds. Their machines are engineered to maximize efficiency, reduce costs, and promote sustainable manufacturing practices.

KBL Machinery goes beyond product delivery by offering comprehensive after-sales support, including operator training, maintenance services, and a reliable supply of spare parts. By partnering with KBL Machinery, manufacturers gain access to cutting-edge technology that supports long-term growth and competitiveness in the market.

| Fonctionnalité | Benefit |

|---|---|

| Precision Engineering | Ensures high-quality, consistent output for diverse construction needs |

| Efficacité énergétique | Lowers production costs while supporting sustainable practices |

| Versatile Applications | Compatible with stone moulds, Moules pour blocset Moules pour briques de route |

| Robust Durability | Designed for long-term performance in demanding industrial environments |

| Comprehensive Support | Offers training, maintenance, and spare parts for uninterrupted operations |

KBL Machinery continues to set the benchmark for excellence in the manufacturing industry, providing advanced solutions that drive efficiency and sustainability in brick and block production.