Expert Insights: How to Choose the Best Paving Mold for Your Business

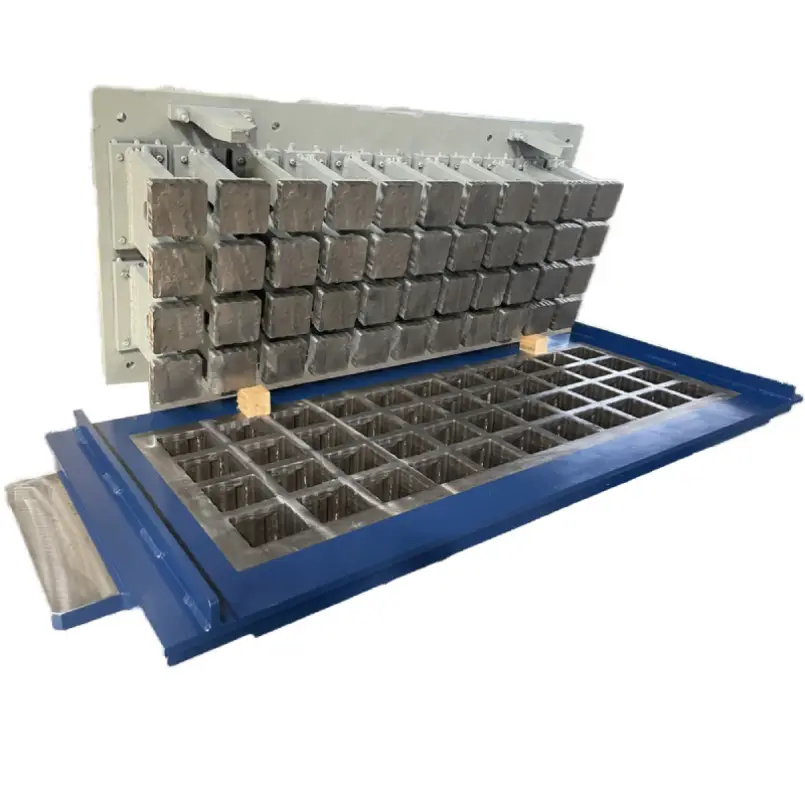

Selecting the best paving mold for your business is a critical decision that can significantly impact production efficiency and product quality. KBL Machinery, a trusted fournisseur de matériel de construction, emphasizes the importance of aligning your mould selection with your production goals. Whether you need moulds for high-volume manufacturing or specialized block designs, it's essential to select Moules pour blocs that fit the needs of your production line. KBL Machinery's precision-engineered moulds ensure consistent block size and quality, reducing errors and material waste while improving the structural integrity of the finished product.

Durability and material quality are also key considerations when selecting a paving mold. KBL Machinery offers Moules pour briques de route made from high-grade steel and other robust materials that withstand continuous use in heavy-duty environments. The longer lifespan of these moulds reduces the need for frequent replacements, helping lower long-term operational costs. Additionally, durable Moules pour blocs contribute to maintaining consistent production output, which is vital for businesses handling large-scale projects.

Customization is another critical factor. KBL Machinery provides customizable paving molds et Moules pour briques de route tailored to your business's unique needs. Whether you need specific block sizes, shapes, or configurations, these moulds offer flexibility in production, ensuring both efficiency and product excellence. Choosing the right paving mold not only optimizes production but also gives you a competitive edge in the marketplace.

| Key Consideration | Importance in Choosing a Paving Mold |

|---|---|

| Material Quality | Ensures durability, reducing frequent replacements. |

| Precision | Guarantees consistent block size, minimizing defects. |

| Customization | Allows for tailored solutions to meet specific project needs. |

| Durability | Provides long-term value by reducing maintenance and replacement costs. |

How to Avoid Common Defects in Paving Molds

| Defect | Prevention Strategy by KBL Machinery |

|---|---|

| Misalignment | Proper alignment of the paving mold during setup is critical to achieve uniform blocks. KBL Machinery designs precision-engineered Moules pour blocs for easy alignment, ensuring consistency. |

| Contamination | Dirt and leftover material can cause surface defects. KBL Machinery recommends regular cleaning of the paving molds after each production cycle to maintain their integrity. |

| Incompatible Materials | The raw materials must match the paving mold specifications to avoid cracks or deformation. KBL Machinery advises using compatible materials to prevent excessive wear on the Moules pour blocs. |

| Excessive Pressure | High pressure during production can lead to defects in the blocks. KBL Machinery provides calibration support to ensure that optimal pressure is maintained. |

| Wear and Tear | Even high-quality paving molds may experience wear over time. Regular inspections help identify signs of wear, allowing timely maintenance or replacement. |

| Lubrication | Consistent lubrication of paving molds with moving parts is necessary to prevent friction-related damage. KBL Machinery recommends using high-quality lubricants for smooth operation. |

Pourquoi choisir KBL Machinery as Your Fournisseur de matériel de construction

Choosing KBL Machinery means partnering with a leader in the fournisseur de matériel de construction industry, known for delivering high-quality, innovative products. With a focus on providing advanced paving molds, Moules pour blocset Moules pour briques de route, we ensure every product is designed for maximum efficiency, durability, and precision. Backed by a team of expert engineers and dedicated customer support, KBL Machinery tailors its solutions to meet the unique needs of each client. Our commitment to quality and customer satisfaction ensures businesses achieve superior production performance and long-term success.