Maximize Production Efficiency with Cement Block Moulds

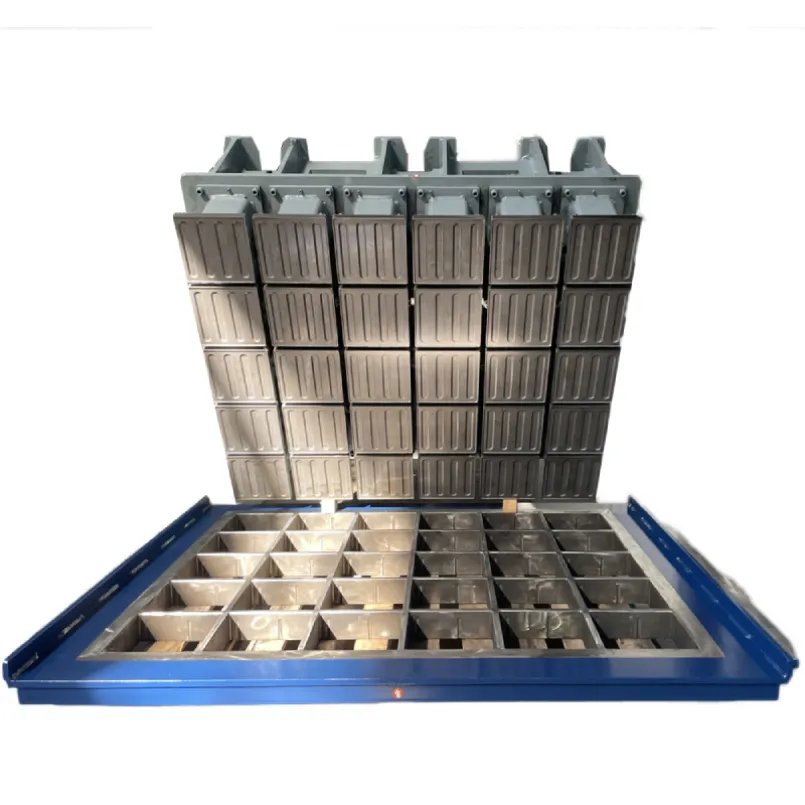

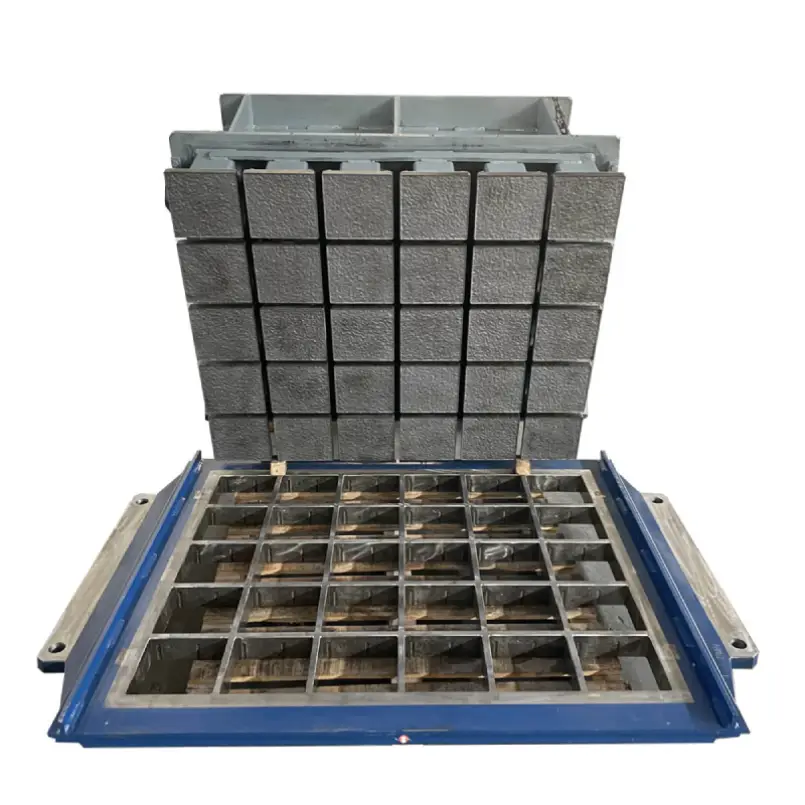

Maximizing production efficiency in block manufacturing calls for solutions that adapt seamlessly to diverse project requirements. KBL Machinery offers high-quality cement block moulds designed to enhance flexibility and precision in production. These Moules pour blocs allow manufacturers to adjust configurations easily, enabling rapid transitions between different block sizes and shapes without downtime. By using versatile cement block moulds, manufacturers can maintain high output rates, meet various customer demands, and streamline their operations—ultimately achieving greater efficiency.

Durability is a key feature of KBL Machinery's cement block moulds. Built with premium materials, these moulds withstand continuous use, reducing the need for frequent replacements and minimizing maintenance costs. This durability ensures that production lines run smoothly, with fewer interruptions, which is essential for large-scale projects. Additionally, KBL Machinery's Block Moulds provide precision engineering, so each block produced meets strict industry standards for strength and uniformity, which is critical for both quality and cost efficiency.

KBL Machinery also offers customizable Moules pour briques de route, allowing businesses to expand their offerings to include various block and brick types without investing in multiple mould sets. The adaptability of these Road Brick Moulds is a valuable asset, especially for manufacturers needing to meet changing market demands. As a trusted construction equipment supplier, KBL Machinery delivers solutions that improve production flexibility and reduce operational costs.

The Sustainable Impact of Cement Block Moulds on Construction

| Aspect | Benefit | KBL Machinery’s Solution |

|---|---|---|

| Reduced Waste | Less material waste through precision production | High-precision cement block moulds reduce defects |

| Extended Mould Longevity | Fewer replacements needed, conserving resources | Durable Moules pour blocs de KBL Machinery |

| Efficient Energy Use | Faster production cycles lower energy demands | Optimized designs in Moules pour blocs |

| Eco-Friendly Material Support | Allows recycled materials in production | Adaptable Moules pour briques de route for sustainability |

| Streamlined Production | Efficient processes reduce overall resource consumption | Reliable fournisseur de matériel de construction innovations |

| Alignment with Green Standards | Blocks produced can meet green certifications | Supports eco-friendly building with KBL Machinery’s moulds |

Reduced Waste: KBL Machinery’s cement block moulds are engineered for precision, resulting in less material waste and contributing to a more sustainable production process.

Extended Mould Lifespan: Crafted with high-quality materials, KBL Machinery's Block Moulds are built to last, reducing the frequency of replacements and conserving manufacturing resources.

Efficient Energy Use: The optimized designs of cement block moulds allow for faster production cycles, lowering energy consumption and promoting sustainable practices.

Support for Eco-Friendly Materials: KBL Machinery's Road Brick Moulds allow manufacturers to use recycled materials, enhancing sustainability in block production.

Streamlined Production: KBL Machinery provides reliable fournisseur de matériel de construction solutions that improve resource efficiency by minimizing downtime and waste.

Alignment with Green Building Standards: Blocks produced with KBL Machinery’s Block Moulds can meet eco-friendly building standards, supporting projects aiming for certifications like LEED.