Fully Automated Cement Block Molds for Sale: A New Era of Efficient Production

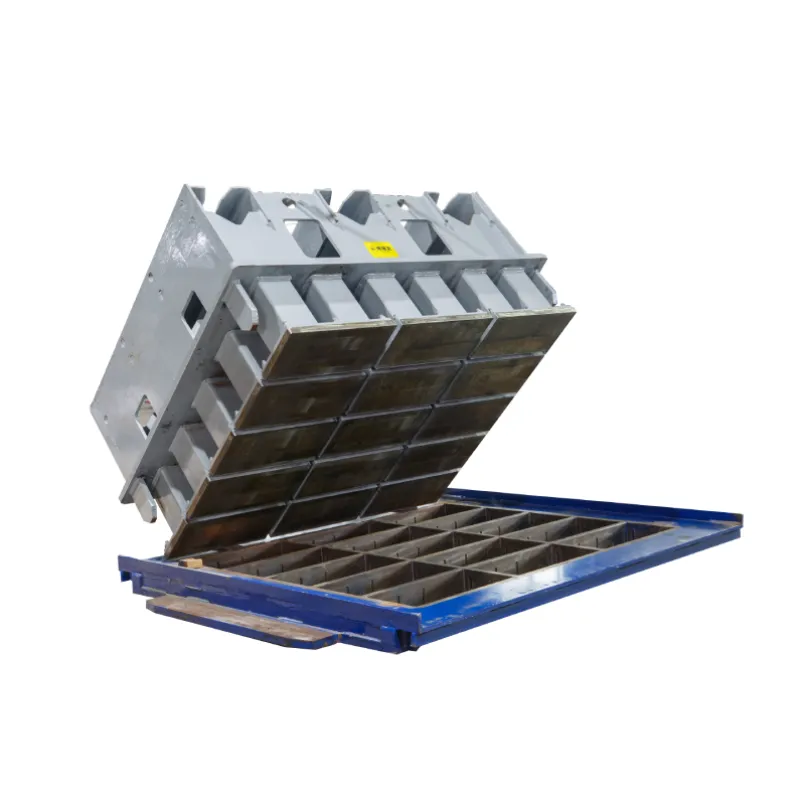

Cement block molds for sale are leading the way in efficient, automated brick production, marking a new era in the construction materials industry. KBL Machinery offers state-of-the-art fully automated machines equipped with robotics, sensors, and AI-driven controls to handle the entire manufacturing process—from mixing raw materials to molding, drying, and stacking. This high level of automation minimizes manual labor, ensuring consistent quality and reducing human error. By streamlining production, these fully automated cement block machines can significantly boost output while maintaining strict control over the size, shape, and composition of each block, resulting in high-quality products that meet industry standards.

A primary benefit of fully automated cement block molds for sale is their ability to operate continuously with minimal downtime, enhancing overall productivity. Designed for efficiency, these machines incorporate real-time monitoring systems that identify and resolve issues before they impact production. Additionally, KBL Machinery’s automated machines optimize the use of raw materials and energy, reducing waste and lowering production costs. This approach not only enhances the sustainability of the manufacturing process but also offers long-term cost savings, making these machines a valuable investment for large-scale production.

Fully automated machines also offer unmatched flexibility, allowing manufacturers to easily switch between different types of blocks, including custom designs, Moules pour blocs, and Road Brick Moulds. This adaptability helps companies meet diverse construction demands, respond quickly to market trends, and maintain a competitive edge. With minimal downtime required for reconfiguration, these machines enable quick adaptation to changing customer preferences, supporting manufacturers in a fast-evolving industry.

Maintenance and Repair of Cement Block Machines: Best Practices for Longevity

- Regular Inspection and Cleaning: Routine inspection and cleaning are essential to extend the lifespan of cement block molds and associated machinery. Daily checks should include belts, gears, and hydraulic systems, while regular cleaning prevents debris buildup that could damage internal systems.

- Lubrication of Moving Parts: Proper lubrication reduces friction and wear on essential parts such as gears, bearings, and chains. Using the correct lubricants and maintaining a regular lubrication schedule prevents malfunctions, overheating, and damage, ultimately enhancing the machine’s efficiency and extending its service life.

- Monitor and Replace Worn Parts: Regularly check key components like molds, belts, and hydraulic seals for signs of wear. Prompt replacement of worn parts ensures continuous operation and avoids costly repairs. Keeping an inventory of essential replacement parts, such as those for Moules pour briques de route, minimizes downtime and maintains production efficiency.

- Calibrate the Machine Periodically: Over time, sensors and precision components can lose calibration, affecting block size and quality. Regular calibration, as recommended by the manufacturer, ensures the machine maintains accuracy and efficiency, especially in fully automated models where precision is critical.

- Employee Training on Operation and Safety: Proper training is vital for machine longevity and workplace safety. Employees should be trained in operating and troubleshooting the machine, recognizing early signs of wear, and understanding safety protocols. Trained operators can prevent minor issues from becoming major repairs, contributing to the machine’s durability and reliable operation.

Why Choose KBL Machinery as Your Construction Equipment Supplier

Choosing KBL Machinery as your fournisseur de matériel de construction means partnering with a team dedicated to providing high-quality, innovative solutions that match your specific needs. With years of industry expertise, KBL Machinery offers a diverse selection of cement block molds for sale, Block Moulds, and Road Brick Moulds that cater to various production capacities and project requirements. Our commitment to customer satisfaction includes exceptional after-sales support, including technical assistance, maintenance, and training. We offer competitive pricing and sustainable technology, helping you stay ahead in the construction market while achieving long-term success.

| Maintenance Practice | Benefits |

|---|---|

| Regular Inspection and Cleaning | Prevents debris buildup and reduces wear. |

| Lubrication of Moving Parts | Minimizes friction and prevents overheating. |

| Monitor and Replace Worn Parts | Ensures smooth operation, preventing breakdowns. |

| Calibrate the Machine Periodically | Maintains accuracy and production consistency. |

| Employee Training | Improves safety and enhances equipment lifespan. |

By investing in KBL Machinery’s cement block molds for sale, Block Moulds, and Road Brick Moulds, businesses gain access to reliable, advanced equipment from a trusted construction equipment supplier, ensuring efficiency, sustainability, and quality in every production run.