Fully Automated Pave Mould Machines: A New Era of Efficient Production

Fully automated pave mould machines are ushering in a new era of efficiency and precision in the production of paving and brick products. These advanced machines incorporate technologies such as robotics, sensors, and AI-driven controls to automate every stage of the manufacturing process, from mixing raw materials to molding, drying, and stacking. This high level of automation minimizes manual intervention, ensuring consistent quality and reducing human error. By streamlining production, fully automated machines significantly increase output while maintaining precise control over paver size, shape, and composition, resulting in high-quality products that meet rigorous industry standards.

One of the primary benefits of fully automated pave mould machines is their ability to operate continuously with minimal downtime, thereby enhancing productivity. These machines feature real-time monitoring systems that detect and address potential issues before they disrupt production. Moreover, they are designed to optimize raw material and energy use, reducing waste and lowering production costs. This not only makes the manufacturing process more sustainable but also translates to long-term cost savings for businesses, making fully automated machines a wise investment for large-scale operations.

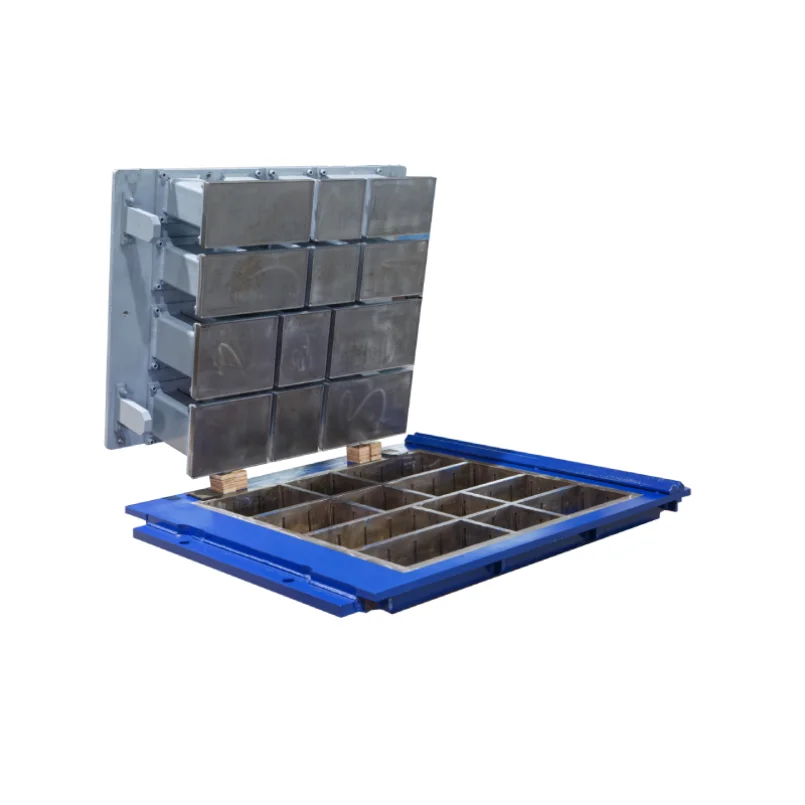

In addition to improved efficiency, fully automated pave mould machines offer exceptional flexibility. They can easily adjust to produce a range of products, including Moules pour blocs and Road Brick Moulds, catering to diverse market demands. With the ability to switch between production runs without requiring extensive reconfiguration, these machines enable manufacturers to respond quickly to customer preferences and market trends. As a result, fully automated pave mould machines not only boost operational efficiency but also enhance a company’s ability to stay competitive in the evolving construction industry.

Maintenance and Repair of Pave Mould Machines: Best Practices for Extending Equipment Lifespan

- Regular Inspection and Cleaning: Conducting regular inspections and thorough cleanings is essential to prolong the life of pave mould machines. Routine checks should cover wear and tear on components like belts, gears, and hydraulic systems. Cleaning prevents dust and debris buildup, which can clog systems and lead to operational inefficiencies.

- Lubrication of Moving Parts: Proper lubrication minimizes friction in moving parts such as gears, bearings, and chains, reducing the risk of overheating and excessive wear. Use the correct lubricant as specified by the manufacturer, and follow a regular schedule to keep the pave mould machine operating smoothly.

- Monitor and Replace Worn Parts: Key components like molds, belts, and hydraulic seals should be monitored for signs of wear. Replacing worn parts promptly prevents unexpected breakdowns and keeps the machine in optimal condition. Maintaining an inventory of spare parts ensures quick repairs and reduces production delays.

- Calibrate the Machine Periodically: Periodic recalibration of sensors and controls is crucial for maintaining accuracy in paver size, shape, and quality. Following the manufacturer’s recommended calibration schedule helps prevent defects and ensures consistent product quality.

- Employee Training on Operation and Safety: Training operators on equipment handling, troubleshooting, and safety is vital to prolong machine life and ensure safe operations. Skilled operators can quickly address minor issues, reducing the risk of serious damage. Regular refresher courses ensure staff remain updated on new features and best practices.

Why Choose KBL Machinery as Your Construction Equipment Supplier

As a trusted fournisseur de matériel de construction, KBL Machinery is dedicated to providing high-quality, innovative solutions tailored to meet diverse production needs. We offer a wide range of machines, including advanced pave mould technology, Block Moulds, and Moules pour briques de route, all designed to optimize efficiency and enhance product quality. Our commitment to customer satisfaction extends beyond delivering exceptional products; we provide comprehensive after-sales support, including training, maintenance, and spare parts, to ensure uninterrupted operations. With competitive pricing, cutting-edge technology, and a focus on sustainability, KBL Machinery is your reliable partner for achieving long-term success in the construction industry.

| Key Maintenance Practice | Description |

|---|---|

| Regular Inspection and Cleaning | Daily or weekly checks and cleanings to prevent buildup and detect wear in belts, gears, and other parts. |

| Lubrication of Moving Parts | Consistent lubrication schedule to minimize friction and ensure smooth operation of essential components. |

| Monitor and Replace Worn Parts | Proactively replacing molds, belts, and hydraulic seals to prevent breakdowns and maintain efficiency. |

| Calibrate Periodically | Recalibrating sensors and controls to maintain product consistency and prevent quality deviations. |

| Employee Training | Training operators on machine use, troubleshooting, and safety, ensuring the longevity of the equipment and maintaining operational efficiency. |