How Interlocking Concrete Block Molds Are Transforming the Building Materials Industry

Interlocking concrete block molds are revolutionizing the building materials industry by bringing automation and advanced technology into brick and block production, greatly enhancing efficiency and precision. KBL Machinery leads the way with innovative designs that incorporate sensors, AI-driven controls, and real-time data analysis to monitor and adjust each production phase, from raw material preparation to shaping and curing. This level of automation reduces the need for manual labor while ensuring consistent block size, strength, and quality. The precision offered by interlocking concrete block molds minimizes waste, optimizes resource use, and cuts production costs, helping manufacturers meet high standards and boost productivity.

Beyond efficiency, interlocking concrete block molds from KBL Machinery support sustainability in the building materials sector. These smart molds optimize energy consumption and raw material usage in real-time, reducing the environmental impact of brick manufacturing. Many of KBL Machinery’s machines are also compatible with eco-friendly materials, enabling the production of blocks aligned with green building practices. This is increasingly valuable as the construction industry emphasizes sustainable solutions to comply with regulations and meet consumer demand for environmentally responsible products. By adopting these advanced molds, manufacturers can stay competitive, producing high-quality blocks with a lower environmental footprint.

Moreover, KBL Machinery’s interlocking concrete block molds offer flexibility and scalability, enabling manufacturers to adapt to market demands easily. With programmable settings, these molds allow for a range of block types, sizes, and compositions, eliminating the need for extensive downtime or manual adjustments. This adaptability enables companies to meet custom orders and changing trends, gaining a competitive edge. Consequently, these molds are transforming not only the production process but also business operations, setting a new standard in the building materials industry for sustainability, efficiency, and responsiveness.

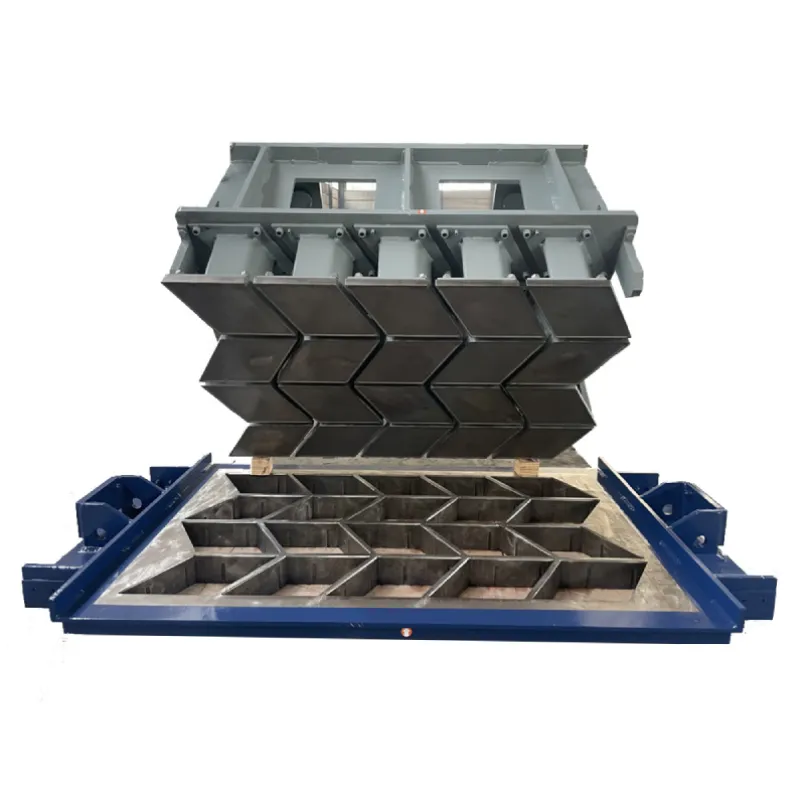

Multi-Functional Block Moulds: Meeting Diverse Market Demands

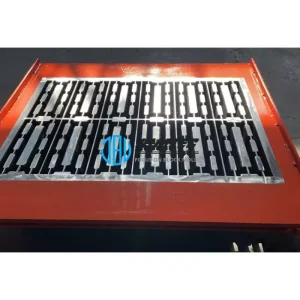

- Versatility in Block Types: KBL Machinery’s Moules pour blocs can produce various shapes and types, including hollow, solid, interlocking, and decorative blocks.

- Adaptability to Different Raw Materials: These Moules pour blocs can process materials like clay, cement, fly ash, and sand, catering to various construction specifications.

- Customization for Specific Projects: Programmable settings enable the molds to adapt quickly for specialized projects, ideal for custom construction requirements.

- Increased Efficiency and Productivity: Combining multiple functions, KBL Machinery’s block molds streamline production, reduce downtime, and boost output.

- Cost-Effectiveness: Multi-functional molds eliminate the need for multiple machines, reducing both investment and maintenance costs while maximizing capacity.

KBL Machinery: Your Trusted Construction Equipment Supplier

KBL Machinery is recognized as a reliable fournisseur de matériel de construction in the brick manufacturing industry, providing high-quality interlocking concrete block molds, Block Moulds, and Moules pour briques de route that cater to diverse production needs. Focusing on innovative, energy-efficient solutions, KBL Machinery helps businesses improve production efficiency and product quality. Their commitment to customer success is demonstrated through robust after-sales support, including training, maintenance services, and spare parts availability. By partnering with KBL Machinery, manufacturers gain a dependable construction equipment supplier dedicated to helping them achieve long-term efficiency and growth in the competitive construction market.

| Key Features | Description |

|---|---|

| Versatility in Block Types | Produces various block shapes, types, and materials. |

| Adaptability to Raw Materials | Handles clay, cement, fly ash, sand, and more. |

| Customization | Programmable settings for project-specific requirements. |

| Efficiency and Productivity | Multi-functional to reduce downtime and increase output. |

| Cost-Effectiveness | Lowers need for multiple machines, reducing costs. |

Choosing KBL Machinery’s interlocking concrete block molds, Block Moulds, and Road Brick Moulds offers businesses the support of a trusted construction equipment supplier, driving efficiency, sustainability, and quality in the building materials industry.