Machine hydraulique de fabrication de blocs de béton en Chine

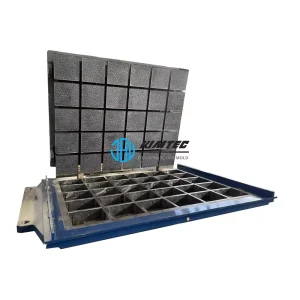

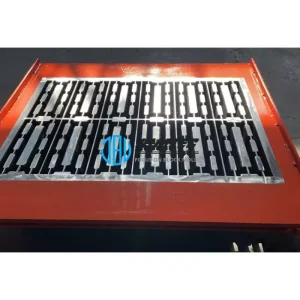

KBL Machinery’s hydraulic concrete block making machine applies hydraulic pressure to create durable and high-strength concrete blocks. This machine automates the entire block-making process, ensuring consistent quality and reducing the need for manual labor. It is designed for high-capacity production, making it suitable for large-scale construction projects. The machine’s energy-efficient operation helps reduce production costs while maintaining high output.

Fully Automated Brick Making Machines: A New Era of Efficient Production

Fully automated machines de fabrication de briques are transforming the construction industry by delivering a new level of efficiency and precision. These advanced machines, such as the hydraulic concrete block making machines provided by KBL Machinery, incorporate robotics, sensors, and AI-driven controls to automate the entire brick manufacturing process—from mixing raw materials to molding, drying, and stacking. The automation minimizes manual labor, ensuring consistent quality and reducing human error. With such innovations, fully automated Machines à fabriquer des blocs increase production capacity while maintaining precise control over brick size, shape, and strength, resulting in higher-quality products that meet stringent industry standards.

One key benefit of fully automated hydraulic concrete block making machines is their ability to operate continuously with minimal downtime. Real-time monitoring systems enable quick detection and resolution of issues before they escalate, enhancing productivity. Additionally, these machines optimize the use of raw materials and energy, reducing waste and lowering production costs. This improved efficiency supports sustainable manufacturing practices, making fully automated machines a sound investment for large-scale operations aiming to reduce environmental impact and achieve long-term cost savings.

Beyond increased efficiency, fully automated Machines à fabriquer des blocs offer unparalleled flexibility. These machines can be programmed to produce various types of bricks, from standard solid bricks to custom-designed options, meeting the diverse needs of modern construction projects. The ability to switch between production runs with minimal reconfiguration enables manufacturers to respond quickly to market trends and customer preferences. This flexibility, combined with enhanced productivity, allows manufacturers to maintain a competitive edge in a rapidly evolving industry.

Maintenance and Repair of Brick Making Machines: Best Practices for Extending Equipment Lifespan

- Regular Inspection and Cleaning:

Regular inspections and cleaning are critical for maintaining machines de fabrication de briques. Inspect components like belts, gears, and hydraulic systems daily or weekly for wear and tear. Cleaning prevents dust and debris buildup, which can damage the machine’s internal systems, ensuring smooth and efficient operations. - Lubrication of Moving Parts:

Proper lubrication is essential to reduce friction and ensure the smooth operation of components such as bearings, gears, and chains. Over time, friction can lead to malfunctions, so regularly lubricating these parts is critical. KBL Machinery recommends using manufacturer-specified lubricants and adhering to a consistent maintenance schedule for hydraulic concrete block making machines. - Monitor and Replace Worn Parts:

Monitoring key parts of Machines à fabriquer des blocs, such as molds, belts, and hydraulic seals, is important to prevent unexpected breakdowns. Replacing worn components in a timely manner ensures uninterrupted operation and avoids costly repairs. A preventive maintenance plan should include regular part replacements, minimizing downtime. - Calibrate the Machine Periodically:

Regular calibration is vital for maintaining precision in fully automated machines. Over time, sensors and controls may drift out of alignment, leading to inconsistent output. Following a recommended calibration schedule helps ensure that the machine de fabrication de briques continues to produce bricks that meet your specifications, maintaining product quality and efficiency. - Employee Training on Operation and Safety:

Proper training is essential for both equipment longevity and safety. KBL Machinery emphasizes the importance of training operators to troubleshoot issues, identify signs of wear, and understand safety protocols. Well-trained operators can quickly resolve minor problems, preventing serious damage to the machine and ensuring safe operation.

Pourquoi choisir KBL Machinery

Choosing KBL Machinery means partnering with a trusted fournisseur de matériel de construction dedicated to providing top-tier, reliable, and innovative solutions. Our machines de fabrication de briques, y compris hydraulic concrete block making machines, are designed to optimize performance, reduce costs, and meet the demands of modern construction. With years of industry experience, KBL Machinery ensures that every product meets the highest standards of quality and efficiency.

Our commitment to customer satisfaction extends beyond delivering exceptional machines. We offer comprehensive after-sales support, including technical assistance, maintenance services, and operator training, to keep your operations running smoothly. With our focus on sustainability, innovation, and cost-effective solutions, KBL Machinery is your ideal partner for long-term success in the competitive construction industry.