Understanding the Technology Behind Modern Hollow Concrete Block Moulds

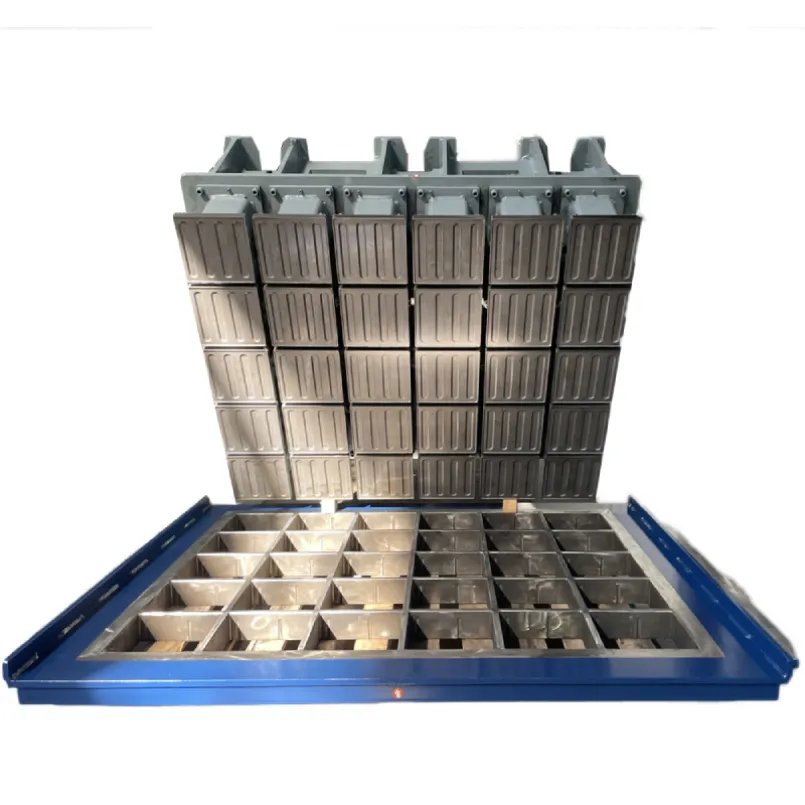

Modern hollow concrete block moulds have transformed the construction industry by incorporating advanced technology to improve efficiency, precision, and sustainability. KBL Machinery integrates state-of-the-art automation and control systems into their hollow concrete block moulds, enabling manufacturers to produce high-quality blocks with minimal manual input. These moulds are engineered to maximize material usage, reduce waste, and ensure uniform block size and strength. The automation also allows for faster production cycles, helping businesses meet high demand while maintaining superior quality.

One major technological advancement in hollow concrete block moulds is the use of hydraulic systems. KBL Machinery’s moulds leverage hydraulic pressure to produce denser and stronger blocks, ensuring durability and structural integrity. This method is not only more efficient but also eco-friendly, reducing the energy required for production. The precision of the hydraulic system ensures better control over the moulding process, resulting in blocks that meet specific industry standards for strength and composition.

Looking to the future, KBL Machinery is pioneering the integration of smart technology into hollow concrete block moulds. With the rise of Industry 4.0, these moulds now feature sensors and data analytics capabilities, enabling operators to monitor the production process in real time, detect potential issues, and optimize performance remotely. This combination of automation, hydraulic efficiency, and smart technology ensures KBL Machinery remains a leader in the market, providing reliable and cost-effective hollow concrete block moulds for construction businesses.

Key Benefits of Using a Hydraulic Hollow Concrete Block Mould

- Résistance supérieure des blocs: KBL Machinery's hydraulic hollow concrete block moulds apply consistent pressure during the moulding process, producing denser and stronger blocks. This durability makes them suitable for a wide range of construction projects.

- Efficacité énergétique: Hydraulic systems are designed for high performance with minimal energy consumption. KBL Machinery ensures that their hydraulic Moules pour blocs are energy-efficient, making production more cost-effective and eco-friendly.

- Précision et cohérence: KBL Machinery’s advanced hydraulic technology guarantees precise control over the moulding process, ensuring each block produced is consistent in size and quality. This consistency reduces waste and enhances production efficiency.

- Réduction de la maintenance: KBL Machinery's hydraulic hollow concrete block moulds are built for longevity and require less maintenance than traditional systems. With robust construction and fewer moving parts, these moulds offer extended machine life and minimal downtime.

KBL Machinery – Trusted Construction Equipment Supplier

At KBL Machinery, we are committed to being a reliable fournisseur de matériel de construction in the industry, delivering high-performance hollow concrete block moulds, Block Moulds, and Moules pour briques de route. Our mission is to provide advanced technology that ensures quality, efficiency, and sustainability. With years of experience, we understand the unique challenges that construction businesses face and offer tailored solutions that enhance production processes. Whether for large-scale construction or smaller projects, KBL Machinery is dedicated to improving your operations with innovative equipment built for long-term reliability.

Beyond offering high-quality machines, KBL Machinery is known for exceptional customer support and dedication to client success. From initial consultation to post-sales service, we build strong relationships with our customers, ensuring that our Block Moulds and other products meet their specific production needs. Our commitment to innovation and a customer-first approach have made KBL Machinery a trusted construction equipment supplier for companies worldwide, helping them reach new heights in productivity and success.

| Key Feature | Description |

|---|---|

| Résistance supérieure des blocs | Hydraulic pressure ensures dense, strong blocks ideal for diverse construction projects. |

| Efficacité énergétique | Designed to minimize energy consumption, supporting eco-friendly practices and reducing operational costs. |

| Précision et cohérence | Advanced technology guarantees uniform block size and quality, reducing waste and improving production efficiency. |

| Réduction de la maintenance | Built to last with fewer moving parts, offering extended machine life and minimal downtime. |

| Real-Time Monitoring | Equipped with smart technology for real-time data analysis, optimizing performance remotely. |

| Customizable Designs | Versatile hollow concrete block moulds for various block shapes and sizes, meeting different project specifications. |