Concrete Block Making Mould: A Comprehensive Buyer’s Guide for 2024

In the evolving construction industry, selecting the right concrete block making mould is critical for companies looking to stay competitive in 2024. KBL Machinery understands that operational success depends on choosing moulds and machines that provide both efficiency and reliability. Key factors to consider include production capacity, level of automation, and mould versatility. KBL Machinery offers a wide range of concrete block making moulds, from semi-automatic to fully automated systems, ensuring that companies of all sizes can find the ideal solution tailored to their specific needs.

One of the key trends in 2024 is the rising demand for sustainable production methods. KBL Machinery leads the market with eco-friendly concrete block making moulds designed to reduce energy consumption and allow the use of recycled materials in production. This approach not only lowers operational costs but also aligns with global sustainability goals, a crucial factor in modern construction. Additionally, KBL Machinery’s moulds are customizable, capable of producing various block types, sizes, and materials, providing the flexibility needed to meet a variety of construction requirements.

When choosing a block making mould, it's essential to consider long-term maintenance and support. KBL Machinery provides durable, high-performance Moules pour blocs and Road Brick Moulds, as well as exceptional after-sales service, including regular maintenance and technical support. In an industry where downtime can impact profitability, investing in moulds from KBL Machinery, a trusted construction equipment supplier, guarantees peace of mind. With cutting-edge technology, a focus on sustainability, and strong customer support, KBL Machinery remains the preferred choice for businesses aiming for success in the brick manufacturing sector in 2024.

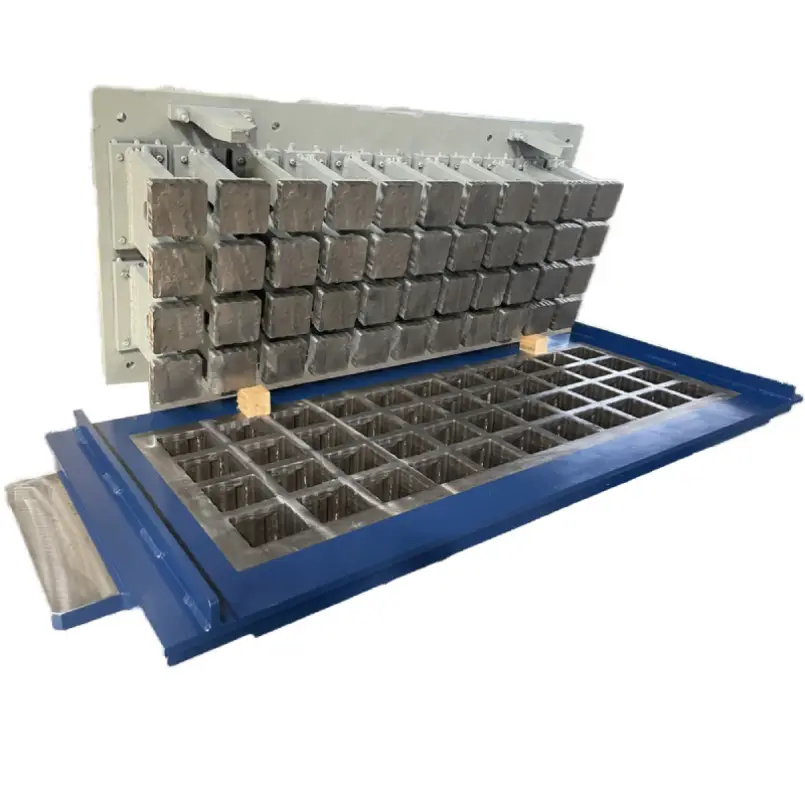

Types of Concrete Block Making Moulds

- Manual Block Moulds: Ideal for small-scale production, these moulds require manual operation. KBL Machinery offers durable manual moulds suited for lower production demands, ensuring ease of use for smaller businesses.

- Semi-Automatic Block Moulds: These combine manual input with automated processes, balancing cost and efficiency. KBL Machinery’s semi-automatic moulds are designed to boost productivity while keeping costs manageable.

- Fully Automatic Block Moulds: These fully automated moulds handle the entire production process, maximizing output with minimal human intervention. KBL Machinery’s fully automated moulds ensure consistent quality, making them perfect for large-scale manufacturing.

- Hydraulic Block Moulds: Using hydraulic pressure, these moulds produce denser, stronger blocks. KBL Machinery specializes in hydraulic moulds, delivering high-performance and durability for demanding construction projects.

- Mobile Block Moulds: Designed for on-site production, KBL Machinery’s mobile block moulds offer flexibility and convenience, ideal for projects requiring blocks produced directly on-site, minimizing transportation costs.

KBL Machinery – A Trusted Construction Equipment Supplier

KBL Machinery is a leader in high-performance concrete block making moulds and other block-making equipment, catering to the diverse needs of the construction industry. With an emphasis on advanced technology, durability, and sustainability, KBL Machinery delivers moulds that enhance production efficiency and ensure consistent quality. Known for customer satisfaction, KBL Machinery provides tailored solutions and ongoing support to help businesses achieve long-term success. For projects large or small, KBL Machinery is the trusted fournisseur de matériel de construction for companies pursuing innovation in construction.

| Fonctionnalité | Description |

|---|---|

| Manual Block Moulds | Simple and durable, ideal for small-scale operations. |

| Semi-Automatic Block Moulds | Balanced solution for cost-effective, moderate production needs. |

| Fully Automatic Block Moulds | High-output option for consistent quality with minimal labor. |

| Hydraulic Block Moulds | Uses hydraulic pressure for durable, strong blocks. |

| Mobile Block Moulds | Convenient on-site solution, reduces transportation costs. |

Choosing KBL Machinery’s concrete block making moulds, Block Moulds, and Moules pour briques de route ensures partnering with a reliable construction equipment supplier dedicated to delivering advanced, efficient, and sustainable solutions for the modern construction industry.