Energy-Efficient and Eco-Friendly Cobblestone Paving Moulds: Driving Sustainable Construction

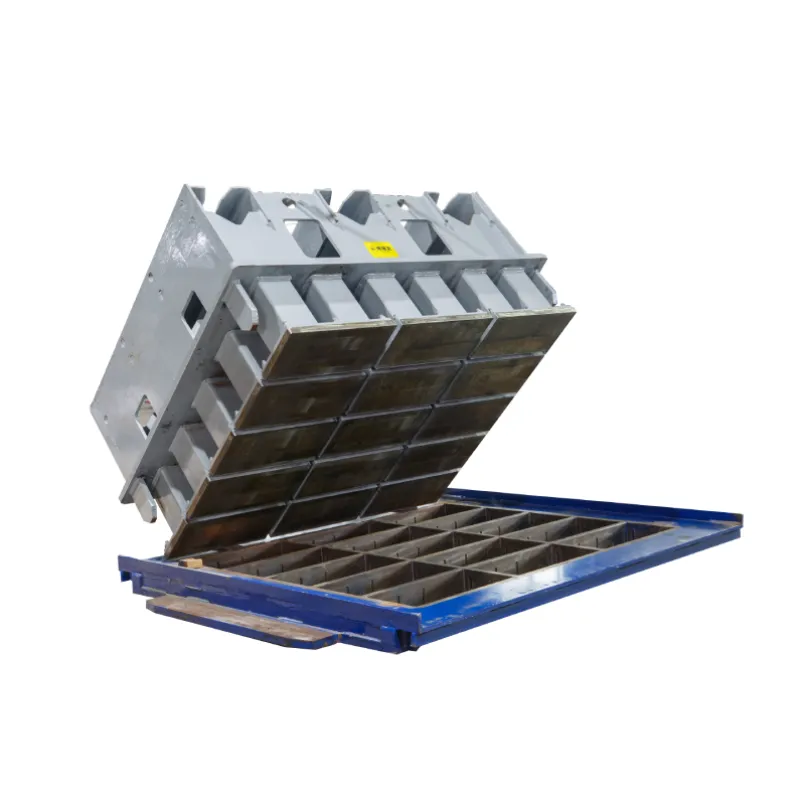

Energy-efficient and eco-friendly cobblestone paving moulds are becoming increasingly essential in driving the global shift toward sustainable construction practices. These moulds are designed to minimize energy consumption while maximizing production output, offering manufacturers a way to reduce operational costs and lower their environmental footprint. By utilizing advanced technologies such as automated controls, optimized firing processes, and minimal water usage, KBL Machinery's cobblestone paving moulds can produce high-quality cobblestones with less energy, aligning with global sustainability goals and regulations. Companies that adopt these energy-efficient moulds not only contribute to environmental conservation but also gain a competitive edge by reducing long-term costs and improving efficiency.

Moreover, eco-friendly cobblestone paving moulds often incorporate the use of sustainable materials, such as recycled or locally sourced raw materials, which further reduces the environmental impact of the construction process. These moulds enable manufacturers to produce cobblestones that are free from harmful chemicals or pollutants, meeting the increasing demand for green building materials. As construction companies and governments emphasize eco-conscious projects, manufacturers using KBL Machinery's cobblestone paving moulds can meet these needs while enhancing their reputation and market share. The adoption of eco-friendly practices becomes a strategic advantage, positioning companies as leaders in the rapidly growing green building sector.

The use of energy-efficient cobblestone paving moulds is not only beneficial from an environmental standpoint but also from a business perspective. The reduction in energy usage translates into lower utility bills, while the ability to produce cobblestones faster and with fewer resources boosts overall productivity. Additionally, the adoption of sustainable technologies can enhance a company's brand image, attracting eco-conscious partners and customers. In an era where sustainability is key to both corporate responsibility and profitability, investing in energy-efficient and eco-friendly cobblestone paving moulds offers a clear path toward long-term growth and industry leadership.

Five Key Factors to Consider When Purchasing Brick and Paving Equipment

- Production Capacity: One of the first considerations when purchasing brick and paving equipment is the machine’s production capacity. Different machines are designed to handle varying levels of output, from small-scale operations to large industrial projects. If your company plans to produce a high volume of cobblestones or bricks daily, investing in equipment with a higher capacity will prevent bottlenecks and ensure timely deliveries. For example, if you are looking to scale up, KBL Machinery’s moules à blocs and road brick moulds can handle substantial output, ensuring the machine you choose can keep up with demand and facilitate business growth.

- Automation Level: The level of automation in brick and paving production varies, with machines ranging from fully manual to semi-automatic and fully automatic systems. Fully automated machines, like those from KBL Machinery, offer minimal human intervention, which can improve production efficiency and reduce labor costs. However, these machines may come with a higher upfront cost. In contrast, semi-automatic or manual machines may be more affordable initially but require more labor and could lead to slower production rates. Understanding your operational complexity and labor resources will help you choose the right level of automation.

- Efficacité énergétique: Energy consumption is a crucial factor when considering long-term operational costs. Energy-efficient equipment, such as KBL Machinery’s cobblestone paving moulds and block moulds, use less power while maintaining high production output, reducing overall energy bills. Additionally, these machines are more environmentally friendly, which helps businesses meet sustainability goals and comply with local regulations. Over time, savings from reduced energy consumption can offset the initial cost of the equipment, making energy-efficient machines a worthwhile investment.

- Quality of Output: The quality and consistency of the bricks or paving stones produced are crucial to the success of your projects. KBL Machinery's road brick moulds and block moulds are designed to produce bricks and stones with consistent strength, size, and durability, ensuring that your construction projects meet industry standards. Poor-quality materials can lead to structural issues and customer dissatisfaction, which can harm your business reputation. Ensure the machine you purchase offers high precision in molding, uniformity in drying, and the ability to handle various raw materials.

- After-Sales Support and Maintenance: After-sales support is an often-overlooked but critical factor. Brick and paving machines require regular maintenance and occasional repairs. When choosing a supplier, ensure they offer reliable technical support, including staff training on machine operation and troubleshooting. KBL Machinery, as a trusted construction equipment supplier, offers comprehensive after-sales service, training, and maintenance to ensure the continued smooth operation of your equipment.

À propos de KBL Machinery

KBL Machinery est un leader fournisseur de matériel de construction, specializing in the design and manufacture of high-performance, energy-efficient, and eco-friendly cobblestone paving moulds, block moulds, and road brick moulds. Our machines are engineered with cutting-edge technology to ensure maximum production capacity, precision, and durability. Known for our commitment to sustainability, KBL Machinery provides advanced equipment that helps businesses reduce their environmental footprint and increase operational efficiency. Our comprehensive after-sales support, including training and technical assistance, ensures that our clients continue to operate at peak performance.

Key Features of KBL Machinery’s Moulds

| Fonctionnalité | Cobblestone Paving Moulds | Moules pour blocs | Moules pour briques de route |

|---|---|---|---|

| Automation | Semi-automatic to fully automatic | Fully automated production | Designed for high-capacity use |

| Efficacité énergétique | Eco-friendly, low energy consumption | Low-power operation | Energy-saving designs |

| Customization | Versatile designs and sizes | Customizable for block types | Adjustable for road applications |

| Material Compatibility | Suitable for various materials | Can handle recycled materials | Produces strong, durable bricks |

| Durability | Long-lasting and weather-resistant | Robust and high-performance | Ideal for heavy-duty use |

| Flexibility | Perfect for residential and commercial projects | Suitable for commercial and residential | Ideal for road and infrastructure |

Why Choose KBL Machinery?

KBL Machinery is a trusted construction equipment supplier, offering a range of high-performance cobblestone paving moulds, block moulds, and road brick moulds that drive efficiency and sustainability in construction. Our machines are built to meet the diverse needs of businesses worldwide, ensuring superior quality and performance. With a focus on customer satisfaction and long-term operational success, KBL Machinery remains at the forefront of the green building movement, providing solutions that help companies thrive in the eco-conscious construction sector.