Paving Mould Machines: A Comprehensive Buyer’s Guide for 2024

As the construction industry evolves, selecting the right paving mould machine is critical for companies looking to remain competitive in 2024. KBL Machinery understands that a successful operation hinges on choosing machines that combine efficiency with reliability. When investing in a paving mould machine, key factors such as production capacity, automation level, and versatility should be prioritized. KBL Machinery offers a broad range of options, from semi-automatic to fully automated systems, ensuring that construction companies of all sizes can find solutions tailored to their specific needs.

One of the significant trends in 2024 is the increasing demand for eco-friendly production methods. KBL Machinery leads the market with its sustainable paving mould machines, designed to minimize energy consumption and support the incorporation of recycled materials. This not only reduces operational costs but also aligns with global sustainability goals, a growing priority in today’s construction landscape. Additionally, KBL Machinery provides machines that are highly customizable, capable of producing a wide variety of pavers and blocks, including Moules pour briques de route. This flexibility allows construction companies to meet diverse project requirements with ease.

Lastly, it’s essential to consider long-term support and maintenance when choosing a paving mould machine. KBL Machinery excels in providing durable, high-performance machines and exceptional after-sales support, including regular maintenance and technical assistance. In an industry where downtime can impact profitability, investing in equipment from KBL Machinery ensures reliability and peace of mind. With cutting-edge technology, a focus on sustainability, and a commitment to customer satisfaction, KBL Machinery is the preferred fournisseur de matériel de construction for businesses aiming to succeed in 2024.

Understanding the Different Types of Paving Mould Machines

- Manual Paving Mould Machines: These machines are operated manually and are best suited for small-scale production. KBL Machinery offers durable manual machines that are easy to operate, making them ideal for businesses with modest production needs.

- Semi-Automatic Paving Mould Machines: Combining manual input with automated processes, these machines strike a balance between cost-effectiveness and productivity. KBL Machinery’s semi-automatic machines are designed for mid-sized businesses looking to increase output without significant expense.

- Fully Automatic Paving Mould Machines: These machines handle the entire production process with minimal human involvement. KBL Machinery provides advanced fully automatic machines that maximize production efficiency and ensure consistent quality, ideal for large-scale projects.

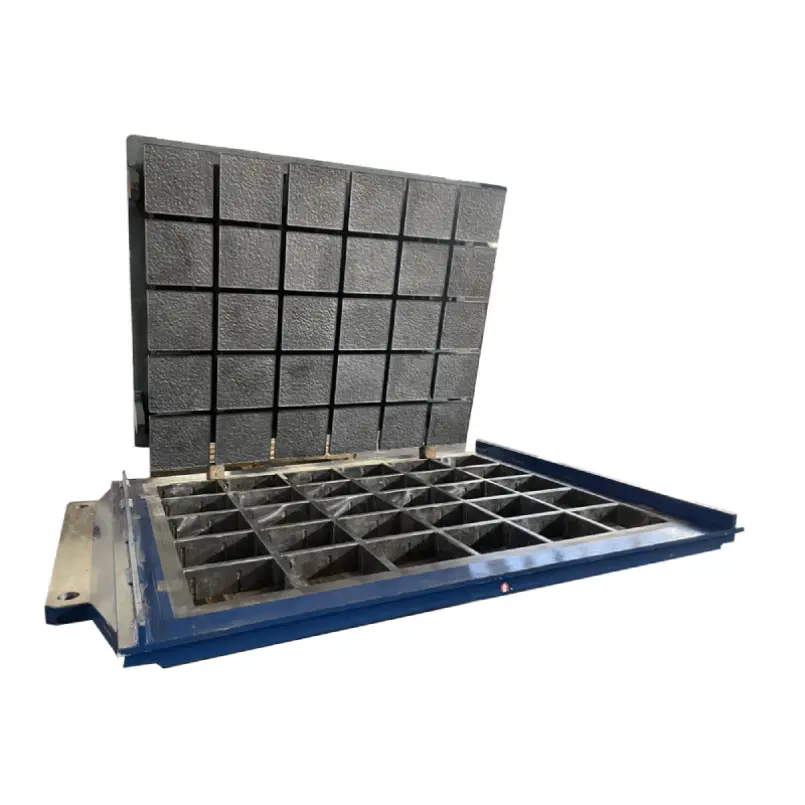

- Hydraulic Paving Mould Machines: Utilizing hydraulic pressure, these machines produce denser, stronger pavers. KBL Machinery’s hydraulic machines offer high performance, making them suitable for producing top-quality pavers et Block Moulds for durable construction.

- Mobile Paving Mould Machines: Designed for on-site production, mobile machines provide flexibility and convenience. KBL Machinery’s mobile models are perfect for construction projects where pavers and blocks need to be produced directly at the site, reducing transportation costs.

Why Choose KBL Machinery as Your Construction Equipment Supplier?

KBL Machinery is a premier construction equipment supplier specializing in high-performance paving mould and block-making machines. With an emphasis on advanced technology, durability, and sustainability, KBL Machinery delivers machines that enhance production efficiency and guarantee consistent quality. Known for exceptional customer support, KBL provides tailored solutions to help businesses achieve long-term success. Whether for small-scale or large industrial projects, KBL Machinery is your trusted partner for construction innovation.

| Key Machine Type | Description |

|---|---|

| Manual Paving Mould Machines | Ideal for small-scale production, offering durability and ease of use for lower demand needs. |

| Semi-Automatic Paving Mould Machines | Balances affordability with productivity, suitable for mid-sized operations seeking efficiency. |

| Fully Automatic Paving Mould Machines | Minimizes human intervention, maximizing output and ensuring uniform quality for large-scale projects. |

| Hydraulic Paving Mould Machines | Produces dense, durable pavers and Moules pour briques de route with hydraulic pressure, ideal for high-quality construction needs. |

| Mobile Paving Mould Machines | Offers on-site production flexibility, reducing transportation costs and adapting to various project locations. |