Comment Cement Brick Molds Are Revolutionizing Concrete Block Production

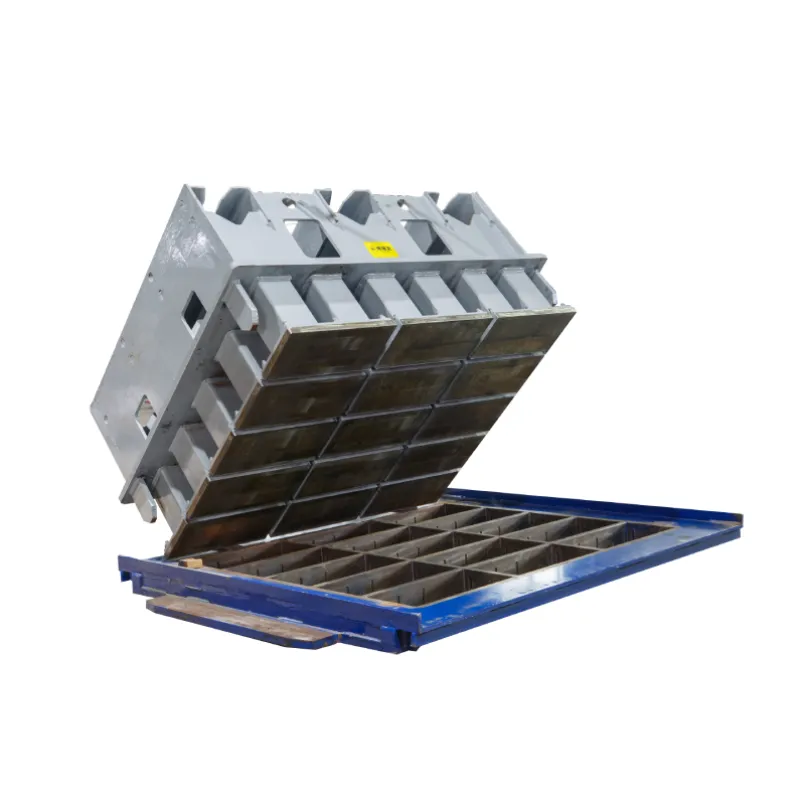

Cement brick molds are transforming the way concrete blocks are produced by introducing greater efficiency, precision, and sustainability to the construction industry. KBL Machinery, l'un des principaux fournisseur de matériel de construction, offers advanced Moules pour blocs that allow manufacturers to produce high-quality blocks with minimal material waste. By utilizing high-precision moulds, manufacturers ensure that every block meets strict size and strength requirements, reducing rework and enhancing productivity. This precision boosts not only operational efficiency but also supports sustainable practices by minimizing excess material usage.

Another key advancement brought by KBL Machinery's cement brick molds is their durability and versatility. Designed with cutting-edge materials, these moulds withstand the high pressure of repeated use without degrading, which significantly increases their lifespan. This longevity reduces the need for frequent replacements, thereby lowering operational costs in the long run. Additionally, KBL Machinery offers customizable mould designs, allowing manufacturers to switch between different block sizes and shapes, catering to various construction project needs without compromising on quality or speed.

Incorporating KBL Machinery's cement brick molds into production lines also contributes to environmental sustainability. These moulds support the use of recycled materials and eco-friendly additives, ensuring that manufacturers can produce durable, high-quality blocks while reducing their environmental impact. With the growing demand for sustainable construction materials, these moulds enable businesses to meet industry standards while maintaining high production efficiency.

Understanding the Cost-Benefit of High-Quality Cement Brick Molds

| Cost Factor | Benefit |

|---|---|

| Initial Investment vs. Long-Term Savings | While cement brick molds may have a higher upfront cost, their durability leads to fewer replacements and lower long-term operational expenses. |

| Enhanced Production Efficiency | KBL Machinery's Block Moulds ensure consistent block dimensions and strength, reducing defects and rework, thus increasing production output. |

| Improved Product Quality | High-quality moulds ensure that blocks meet industry standards for strength and durability, resulting in fewer returns and higher customer satisfaction. |

| Reduced Downtime and Maintenance | Durable cement brick molds de KBL Machinery minimize the need for frequent repairs, keeping production lines running smoothly and avoiding costly delays. |

| Customization Flexibility | Customizable moulds allow manufacturers to easily adapt to changing market demands, giving businesses a competitive edge while maintaining cost-effective production. |

By investing in high-quality cement brick molds, manufacturers can realize significant savings in operational costs and improve overall production efficiency.

Pourquoi choisir KBL Machinery

Au KBL Machinery, we pride ourselves on delivering top-tier cement brick molds, Moules pour blocset Moules pour briques de route that enhance production efficiency and product quality. As a trusted fournisseur de matériel de construction, we understand the evolving needs of the construction industry and provide customized solutions tailored to meet those demands. Our dedication to innovation and reliability is backed by professional engineering support and competitive pricing, ensuring that our clients receive the highest value for their investment. Choosing KBL Machinery means partnering with a company focused on your long-term success, with an emphasis on quality, sustainability, and operational efficiency.