¿Qué máquinas se utilizan para fabricar ladrillos?

19 de septiembre de 2024

Kimberley, un líder proveedor de máquinas para fabricar ladrillos, está a la vanguardia de la oferta de soluciones avanzadas en la industria de fabricación de ladrillos. Los ladrillos son un material de construcción fundamental, utilizado en todo el mundo desde hace siglos. Sin embargo, la forma de fabricarlos ha evolucionado drásticamente gracias al desarrollo de maquinaria especializada. ¿Qué máquinas se utilizan hoy en día para fabricar ladrillos? Este artículo explora la maquinaria básica para la producción de ladrillos y destaca la innovación que Kimberley aporta a esta industria esencial.

Principales tipos de máquinas utilizadas en la fabricación de ladrillos

El proceso de fabricación de ladrillos implica varias etapas, desde la mezcla de materias primas hasta el moldeado y, por último, la cocción de los ladrillos. He aquí los principales tipos de maquinaria para fabricar ladrillos:

1. Extrusoras de ladrillos de arcilla La extrusora de ladrillos de arcilla es una de las máquinas más tradicionales utilizadas en la fabricación de ladrillos. Funciona prensando materias primas como arcilla, pizarra y arena a través de una matriz para formar largas tiras de arcilla en forma de ladrillo. A continuación, estas tiras se cortan en ladrillos individuales, se secan y se cuecen. Las extrusoras de ladrillos de arcilla son muy eficaces y se utilizan habitualmente en instalaciones de producción de ladrillos a gran escala.

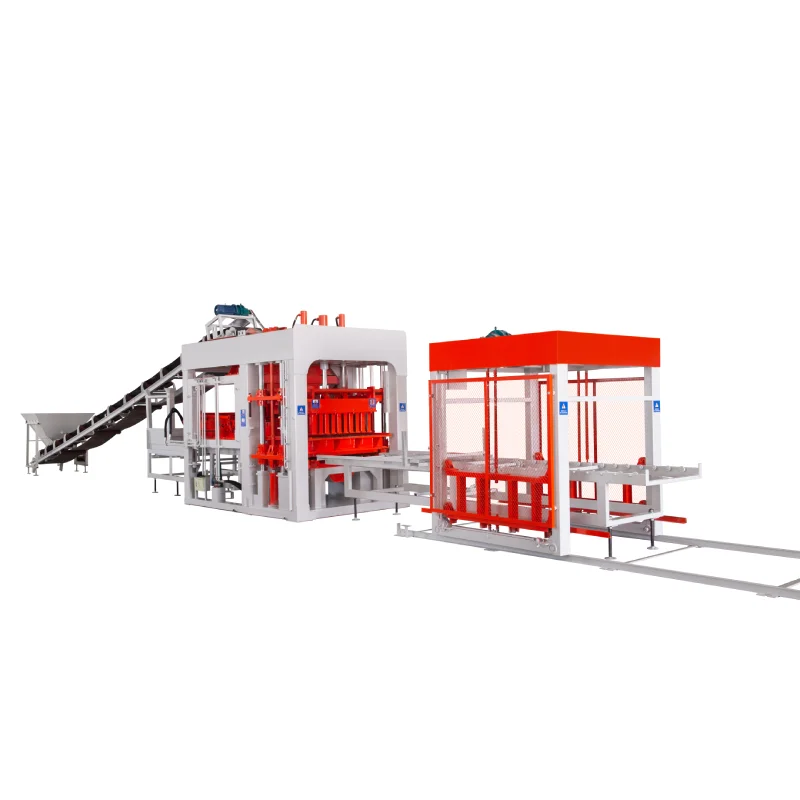

2. Máquina automática de fabricación de ladrillos En la fabricación moderna de ladrillos, máquinas para la fabricación automática de ladrillos son cada vez más populares debido a sus operaciones automatizadas y altos índices de producción. Estas máquinas se encargan de todo, desde la alimentación de materias primas hasta el moldeado, la compresión y la expulsión de ladrillos sin apenas intervención humana. Gracias a su avanzada automatización, las máquinas de fabricación automática de ladrillos de Kimberley garantizan precisión, consistencia y un importante ahorro de mano de obra, lo que las hace ideales para grandes proyectos y producción a escala industrial.

3. Máquinas de bloques de enclavamiento Máquinas de bloques encajables están especializados en la producción de ladrillos entrelazados que encajan entre sí sin necesidad de mortero. Estos ladrillos se utilizan a menudo en la construcción para pavimentar, construir muros de contención e incluso en proyectos de viviendas de bajo coste. Kimberley ofrece máquinas de bloques encajables de alto rendimiento, conocidas por producir ladrillos duraderos y uniformes. Estas máquinas permiten crear estructuras ecológicas y sostenibles, ya que minimizan la necesidad de materiales de construcción adicionales como el cemento.

4. Prensas hidráulicas Las prensas hidráulicas para ladrillos se utilizan en la producción de ladrillos de hormigón. Estas máquinas utilizan presión hidráulica para comprimir mezclas de hormigón en moldes de ladrillos, creando ladrillos de gran resistencia y durabilidad. Las prensas hidráulicas son adecuadas para producir ladrillos macizos, huecos y perforados, lo que las convierte en una solución versátil para diversas necesidades de construcción.

Maquinaria avanzada de Kimberley para la fabricación de ladrillos

Kimberley es un reputado proveedor de equipos de vanguardia para la fabricación de ladrillos. Nuestros dispositivos están diseñados para ser lo más sostenibles y eficientes posible, cumpliendo los requisitos más estrictos de la industria. Desde extrusoras de arcilla convencionales hasta sistemas completamente automatizados como la máquina de producción automática de ladrillos, tenemos una gran variedad de maquinaria entre la que elegir. Debido a su capacidad para reducir los residuos y aumentar la eficiencia de la construcción, nuestras máquinas de bloques entrelazados son especialmente apreciadas en los mercados concienciados con el medio ambiente.

Kimberley diseña sus máquinas pensando en la calidad y la innovación tecnológica, atendiendo a las exigencias cada vez mayores de la construcción contemporánea. Nuestros equipos ofrecen un rendimiento y una fiabilidad inigualables tanto para construcciones residenciales modestas como para grandes proyectos de infraestructuras.

Conclusión

El mundo de la fabricación de ladrillos ha experimentado un inmenso progreso con la llegada de maquinaria especializada. Desde las tradicionales extrusoras de arcilla hasta las vanguardistas máquinas de fabricación automática de ladrillos y las máquinas de bloques entrelazados, el sector ha adoptado la automatización y la innovación para hacer frente a los retos de la construcción moderna.

Si desea más información o conocer nuestra gama de maquinaria para la fabricación de ladrillos, póngase en contacto con Kimberley hoy mismo o visite nuestro sitio web.