Understanding the Technology Behind Modern Interlocking Mould Block Machines

Modern interlocking mould block machines have transformed the construction industry by integrating advanced technology to enhance efficiency, precision, and sustainability. KBL Machinery, a trusted proveedor de maquinaria de construcción, has been a pioneer in incorporating cutting-edge automation and control systems into their block-making machines. This innovation allows manufacturers to produce high-quality blocks with minimal manual intervention, ensuring optimized material usage, reduced wastage, and consistent block size and strength. KBL Machinery’s automation also enables faster production cycles, helping businesses meet high demands without compromising on quality.

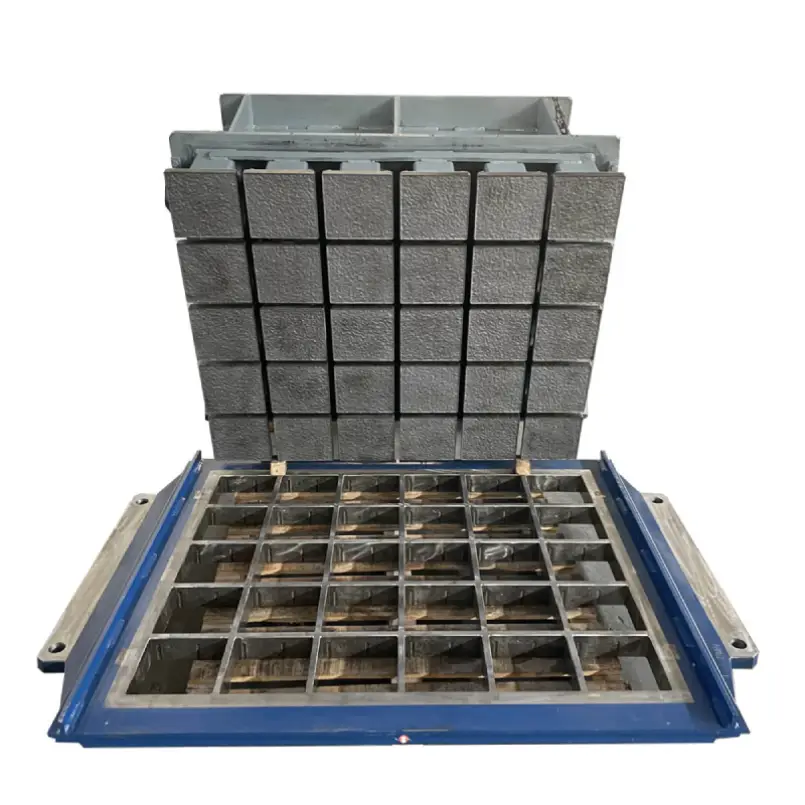

A significant technological advancement in these machines is the incorporation of hydraulic systems. KBL Machinery’s machines utilize hydraulic pressure to create denser and stronger blocks, including interlocking mould designs and Road Brick Moulds, ensuring durability and structural integrity. This hydraulic process is both efficient and eco-friendly, as it reduces the energy needed for production. The precision of these hydraulic systems allows for better control over the block-making process, resulting in blocks that meet stringent industry standards for strength and composition.

Looking ahead, KBL Machinery is leading the way by integrating smart technology into interlocking mould block machines. With the rise of Industry 4.0, their machines are now equipped with sensors and data analytics capabilities, allowing operators to monitor the production process in real-time, diagnose potential issues, and optimize performance remotely. This combination of automation, hydraulic efficiency, and smart technology ensures that KBL Machinery continues to be a reliable construction equipment supplier, providing machines that are not only innovative but also cost-effective for construction businesses.

Key Benefits of Using Hydraulic Interlocking Mould Block Machines

- Superior Block Strength: KBL Machinery's hydraulic machines apply consistent pressure during the molding process, resulting in denser, stronger blocks. This makes them ideal for a variety of construction projects, including Moldes para ladrillos viales.

- Eficiencia energética: Hydraulic systems are designed to minimize energy consumption while maintaining high performance. KBL Machinery’s machines are built to be both cost-effective and environmentally friendly.

- Precisión y coherencia: The advanced hydraulic technology in KBL Machinery’s interlocking mould machines guarantees precise control over the molding process, ensuring that each block produced is uniform in size and quality. This consistency helps reduce material waste and improves overall production efficiency.

- Reduced Maintenance: KBL Machinery’s hydraulic block making machines are built to last, with robust construction and fewer moving parts. This durability results in longer machine life, reduced downtime, and lower maintenance costs.

KBL Machinery: A Trusted Construction Equipment Supplier

At KBL Machinery, we are dedicated to being a reliable construction equipment supplier that offers innovative, high-performance solutions for block and brick making. Our focus on advanced technology ensures superior quality, efficiency, and sustainability. Whether it’s for large-scale construction projects or smaller projects, our interlocking mould machines, Moldes para bloques, and Road Brick Moulds provide tailored solutions to meet specific production needs.

Our customer-first approach, from initial consultations to after-sales support, sets us apart. KBL Machinery ensures that our clients receive not only top-quality machinery but also dedicated support to achieve long-term success in the competitive construction market.

| Característica principal | Descripción |

|---|---|

| Superior Block Strength | Consistent hydraulic pressure produces durable blocks, including interlocking mould y Moldes para ladrillos viales. |

| Eficiencia energética | Minimizes energy usage, lowering operational costs and supporting sustainable production. |

| Precisión y coherencia | Ensures uniform block size and quality, reducing material waste and boosting production efficiency. |

| Reduced Maintenance | Durable design with fewer moving parts lowers maintenance requirements and extends equipment lifespan. |

| Advanced Smart Technology | Equipped with real-time monitoring and diagnostics for efficient performance optimization and remote troubleshooting. |