The Technology Behind Modern Concrete Walkway Molds

The innovation in concrete walkway mold production has transformed construction practices, driven by advancements in automation and hydraulic technology. KBL Machinery is at the forefront of this transformation, offering machines that are designed to create high-quality molds efficiently and sustainably. By integrating smart control systems, KBL Machinery’s equipment ensures precision in mold production, optimizing material usage and reducing waste. These features make it possible to meet the growing demand for consistent, durable concrete walkway mold designs in the construction industry.

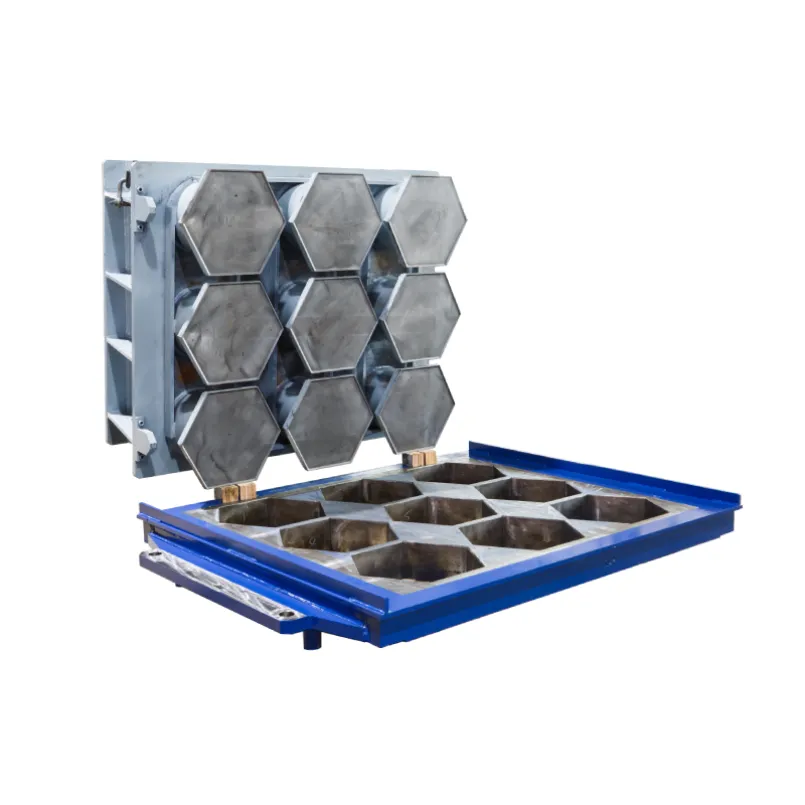

A key feature of KBL Machinery’s block and mold-making machines is their hydraulic systems, which apply uniform pressure to create stronger and denser products. This technology not only enhances the structural integrity of molds and blocks but also reduces energy consumption, making the process more eco-friendly. Whether producing Moldes para bloques, Moldes para ladrillos viales, or custom concrete walkway solutions, KBL Machinery’s machines deliver the versatility needed to meet diverse construction requirements.

Looking to the future, KBL Machinery is committed to advancing smart technology in its machines. Industry 4.0 innovations, such as real-time production monitoring and data analytics, enable operators to oversee processes remotely, optimize performance, and identify maintenance needs proactively. With these advancements, KBL Machinery ensures that their customers can rely on machines that combine sustainability, efficiency, and cutting-edge technology.

Key Benefits of Using Hydraulic Concrete Walkway Mold Machines

- Mayor durabilidad: Hydraulic systems apply consistent pressure, resulting in robust concrete walkway mold designs that withstand heavy usage and varying environmental conditions.

- Energy Savings: KBL Machinery’s hydraulic block and mold machines are optimized for energy efficiency, consuming less power while maintaining high productivity. This reduces costs and supports eco-friendly construction practices.

- Ingeniería de precisión: The advanced hydraulic systems ensure uniformity and high quality across all products, whether producing Block Moulds, Moldes para ladrillos viales, or walkway molds.

- Low Maintenance Requirements: With fewer moving parts and robust construction, KBL Machinery’s machines require minimal upkeep, leading to reduced downtime and greater operational efficiency.

KBL Maquinaria: Su proveedor de confianza de maquinaria de construcción

As a globally recognized proveedor de maquinaria de construcción, KBL Machinery is dedicated to providing innovative solutions for mold and block manufacturing. Our advanced machines cater to a variety of needs, including the production of concrete walkway molds, Block Moulds, and Road Brick Moulds. Each machine is meticulously designed to maximize productivity, enhance durability, and ensure environmental sustainability.

KBL Machinery goes beyond simply offering high-performance equipment. We are committed to building long-term partnerships with our clients by providing exceptional customer service and tailored solutions. From initial consultations to after-sales support, our team works closely with customers to ensure their specific production needs are met. This dedication to excellence has made KBL Machinery a trusted partner for businesses worldwide.

| Característica | Beneficio |

|---|---|

| Hydraulic Technology | Ensures strength and durability of concrete walkway molds |

| Eficiencia energética | Reduces operational costs and supports eco-friendly practices |

| Precision Production | Guarantees consistent quality in molds and blocks |

| Bajo mantenimiento | Minimizes downtime with durable, robust machine design |

| Smart Technology | Real-time monitoring and analytics for optimized performance |

KBL Machinery continues to lead the way in manufacturing reliable, efficient, and sustainable solutions for concrete walkway mold production, helping businesses achieve unparalleled success in the construction industry.