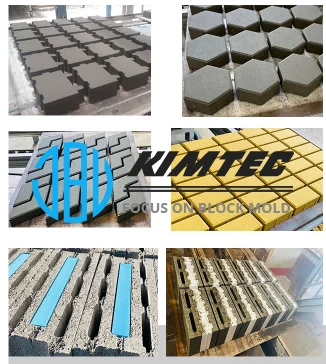

MASA HESS Hollow Interlocking Concrete Block Molds for Brick Factories

Brief introduction

Our molds use alloy steel, and we craft wearable parts from wear-resistant materials. We perform heat treatments to maximize wear resistance, continuously improving our processing techniques to ensure our molds deliver excellent performance in the market.

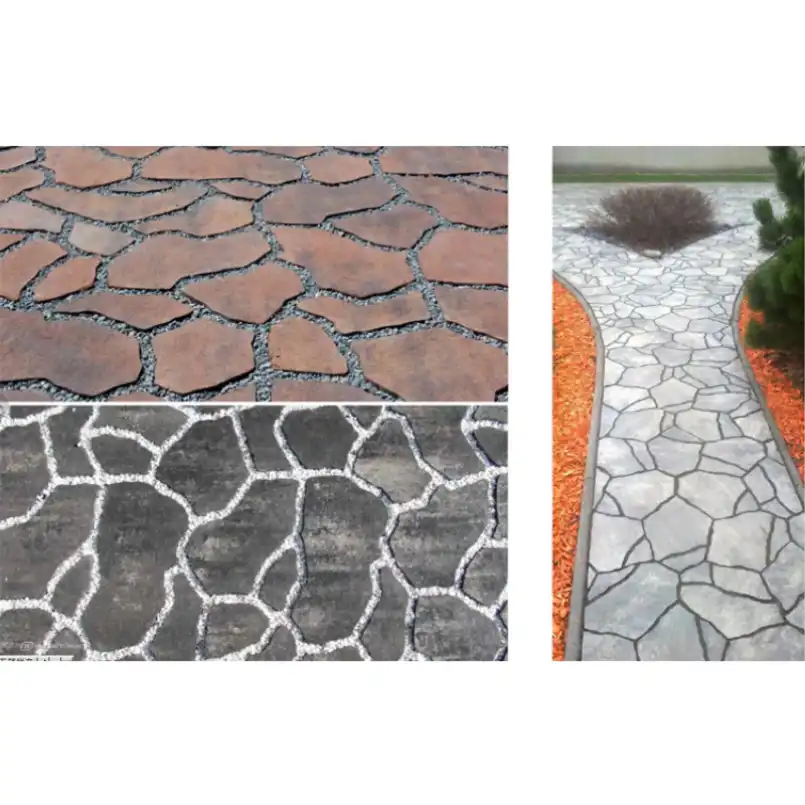

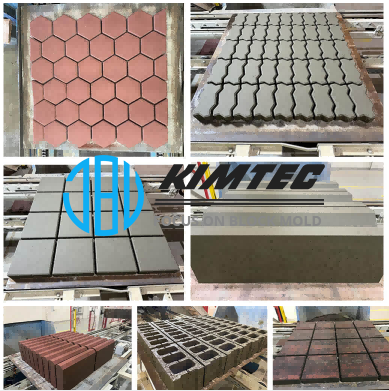

Currently, our factory focuses on producing road bricks, hollow bricks, square bricks, grass bricks, and other brick molds.

Our molds fit almost all types of machines, both domestic and international, and are widely utilized in various equipment like Masa, Hess, Zenith, Tiger, Bessel, and Ritu. Consequently, they offer versatile compatibility.

Our Molds' Technical Data

Mold Features:

- We employ the most advanced assembly process.

A: Utilize advanced welding technology and stress-relief treatments, as internal stresses can deform components, leading to tolerance errors and malfunctioning parts. Thus, we ensure minimal deformation during heat treatment and conduct tempering post-quenching to eliminate stress for reliable mold performance.

B: Maintain a press foot clearance of 0.3-0.8mm for machine compatibility.

C: Use standard parts and apply anti-loosening treatments to high-strength connection bolts.

D: Follow standardized assembly processes for easy part replacement.

E: Craft with high-quality wear-resistant steel plates.

F: Incorporate mold damping functions for enhanced performance.

G: Enable digital free surface designs for versatile applications.

- To guarantee mold durability, we implement carbonitriding heat treatment (60-65HRC).

A: Harden die frames and press feet to 60-65HRC.

B: Ensure a minimum hardening depth of 1.2mm for lasting strength.

About Our Packaging

PREGUNTAS FRECUENTES:

- How can I receive a quote?

A. Send us detailed drawings of your required blocks, and we will provide a quote based on those.

B. Without drawings, inform us of the block type, like hollow or solid, and share a picture with dimensions: length, width, thickness in mm.

C. What are your pallet dimensions?

D. Provide the tamper head size and mold height.

E. Explain how your mold connects to your machine; supply connection drawings if possible. We'll quote promptly after receiving your details.

- What is the delivery time?

Expect 20-25 workdays for standard molds post-receiving deposit, and 30-40 workdays for high-end molds.

- How is the transport packaging?

We use wooden crates with plastic film, or follow buyer's specifications.

- Will the new mold fit my machine?

We've crafted molds for various brands, maintaining records. Thus, likely, we have a suitable option for you.

For assurance, measure your current mold or send photos for assessment. After confirming measurements, we ensure the mold fits seamlessly. No worries needed!

- What are the payment terms?

Pay a 50% advance via T/T to initiate your order, and settle the balance before shipment.

- How can I contact you?

Reach out through WeChat/WhatsApp: +86-1330506196 or +86-18960287187. Thanks!