Productos

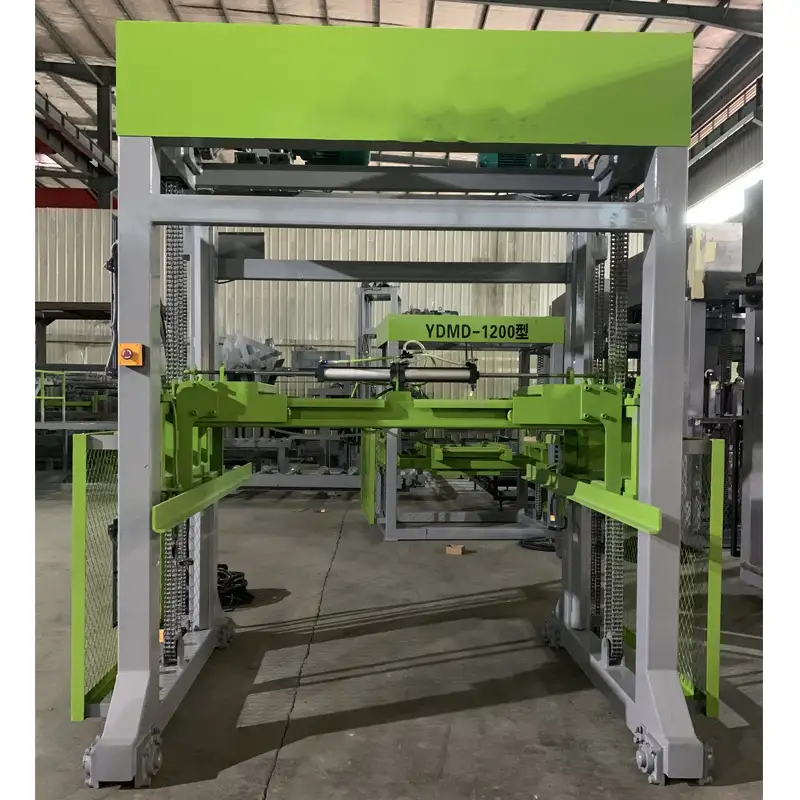

XX-MD 1200 preformed-holes dry block packing system is suitable for palletizing of dry finished blocks of simple block making production line, belonging to semi-automatic palletizing production line, which is independently set up near the product maintenance yard, and can also be connected in series in the block production line to implement on-line palletizing.

Working Process:

The automatic preformed-holes dry block packing system can separate the bricks of different types and specifications produced by different types of brick machines, reassemble the blocks, and finally form a square stack of about one meter. Cross palletizing is carried out, and the fork brick hole position can be generated automatically according to the need. The palletizing height can be up to 1450mm.

After the palletizing is completed, it can be palletized and output through a heavy chain conveyor, which can be packed manually or equipped with an automatic baling machine. Each node on the whole production line has a pre-stored position to save the forklift running time.

Inspection and Maintenance:

The whole system adopts PLC and touch screen control, cooperate with laser induction and intelligent sensor to realize unmanned automatic operation, and automatically stop the alarm and display the fault location when a fault occurs, which can be easily eliminated without professional and technical personnel. Just 2-4 workers can cover the whole brick collection work, save a lot of labor cost. Equipped with remote control systems and cloud data equipment manufacturers can solve all problems in the office all the time.

Working Principle:

The operation of the equipment is controlled by electricity, gas and liquid respectively, which does not interfere with each other and acts coherently.

Lifespan:

More than 6~10years, low maintains cost.