Categorías de productos

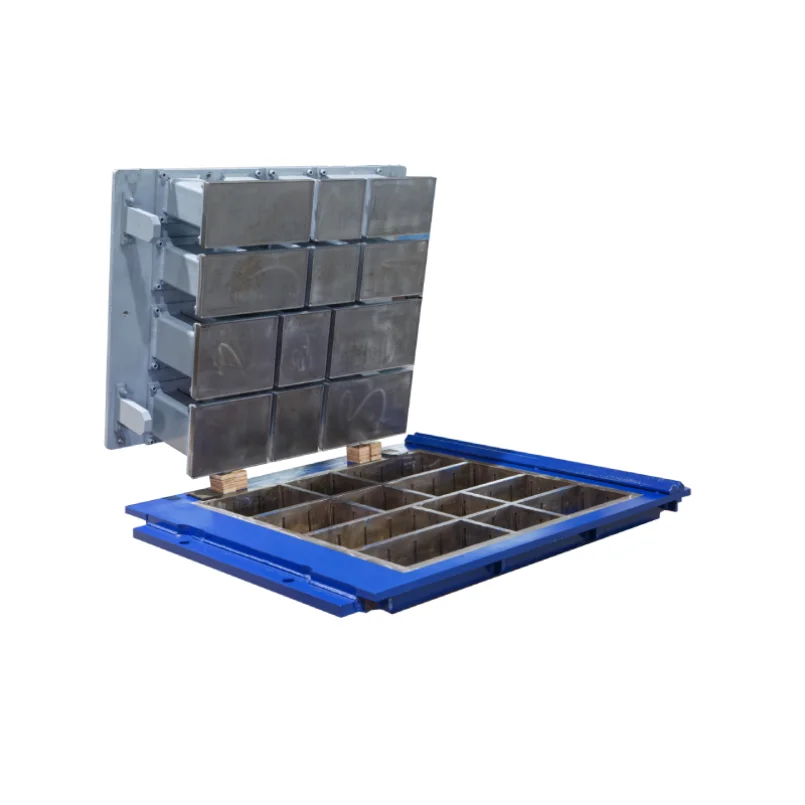

High-Capacity Paving Stone Molds: Ensuring Reliable Productivity for Large-Scale Projects

High-capacity paving stone mold machines are essential for ensuring efficient and reliable productivity in large-scale projects, where consistency and speed are crucial. KBL Machinery designs these machines to handle high volumes of raw materials, enabling the production of a significant number of paving stones or bricks in each cycle. This makes them ideal for large construction projects requiring substantial quantities in a short period. With advanced automation and precision controls, KBL Machinery’s high-capacity machines run continuously with minimal downtime, ensuring manufacturers can meet demanding schedules while maintaining high product quality. This capability to produce at scale without compromising standards is key to meeting the needs of complex, large-scale projects.

One of the key advantages of paving stone mold machines is their ability to streamline production, eliminating bottlenecks and increasing operational efficiency. KBL Machinery integrates automation for material mixing, molding, and curing, enabling faster and more accurate production than traditional methods. Equipped with automated batching and real-time monitoring, these machines adjust production parameters on the fly to optimize output and minimize waste. This level of efficiency reduces operational costs and boosts profitability, making them a valuable investment for manufacturers looking to scale up their production capabilities.

Moreover, high-capacity paving stone machines offer flexibility, enabling manufacturers to meet a range of project needs without compromising productivity. These machines can easily be programmed to produce different types of blocks or stones, including Moldes para bloques and Road Brick Moulds, based on the unique requirements of a project. This versatility allows manufacturers to serve a wider client base, from large infrastructure projects to custom designs. By investing in KBL Machinery’s high-capacity machines, manufacturers not only increase production capacity but also improve their ability to adapt to the evolving demands of the construction industry, positioning themselves for long-term success.

Long-Term ROI of Investing in Brick Making Machines: From Costs to Benefits

- Reducción de los costes laborales: One of the immediate benefits of investing in advanced machines like paving stone mold systems is the significant reduction in labor costs. With automation handling most production processes, the need for a large workforce is minimized, lowering both direct wage expenses and associated costs such as training and supervision. In the long term, the savings on labor help offset the initial equipment investment, making these machines cost-effective for businesses focused on optimizing production.

- Mayor eficiencia de la producción: High-capacity machines are designed for rapid production. Automation and optimized systems allow these machines to produce large volumes efficiently, meeting higher demand without extending operational hours. This increase in production efficiency allows companies to meet deadlines, reduce lead times, and accommodate larger projects, all of which contribute to higher profit margins.

- Energy Savings: Modern machines from KBL Machinery include energy-efficient features such as optimized motors and intelligent energy management. These technologies reduce power consumption, lowering utility costs over time. By reducing energy use, companies enhance profitability and align with environmentally sustainable practices—a crucial advantage in today’s industry.

- Consistent Product Quality: Advanced machines produce bricks and stones with consistent dimensions and strength. This reliability minimizes defects and waste, reducing the need for rework and ensuring higher-quality output. Maintaining product consistency builds a stronger reputation and fosters customer loyalty, supporting long-term growth.

- Longer Equipment Lifespan: High-quality machines, including Block Moulds and Moldes para ladrillos viales by KBL Machinery, are built for durability and designed to withstand continuous production. Self-diagnostic systems allow for predictive maintenance, minimizing breakdowns and prolonging the equipment’s lifespan. The durability of these machines enhances ROI by reducing repair costs and downtime.

About KBL Machinery: Your Construction Equipment Supplier

KBL Maquinaria is a premier proveedor de maquinaria de construcción known for high-performance paving stone, brick, and block making machines, including paving stone mold, Block Moulds, and Road Brick Moulds. Specializing in advanced, energy-efficient, and fully automated solutions, KBL Machinery supports a range of projects from small operations to large-scale developments. Our machines are designed to optimize production, enhance efficiency, and reduce costs. We pride ourselves on exceptional after-sales support, providing technical assistance, maintenance, and training to ensure our clients achieve sustained success in the competitive construction industry.

| Característica principal | Descripción |

|---|---|

| Reducción de los costes laborales | Automation lowers labor needs, reducing costs and increasing efficiency. |

| Mayor eficiencia de la producción | High-speed production to meet demand without extended hours. |

| Energy Savings | Energy-efficient systems lower utility costs and support sustainability. |

| Consistent Product Quality | Ensures reliability, reducing defects and waste. |

| Longer Equipment Lifespan | Built to last, minimizing repairs and extending usage life. |

Choosing KBL Machinery’s paving stone mold systems, Block Moulds, and Road Brick Moulds means partnering with a trusted construction equipment supplier committed to enhancing efficiency, sustainability, and quality for manufacturers in the construction industry.