Optimizing Production Processes with Advanced Brick Making Technology

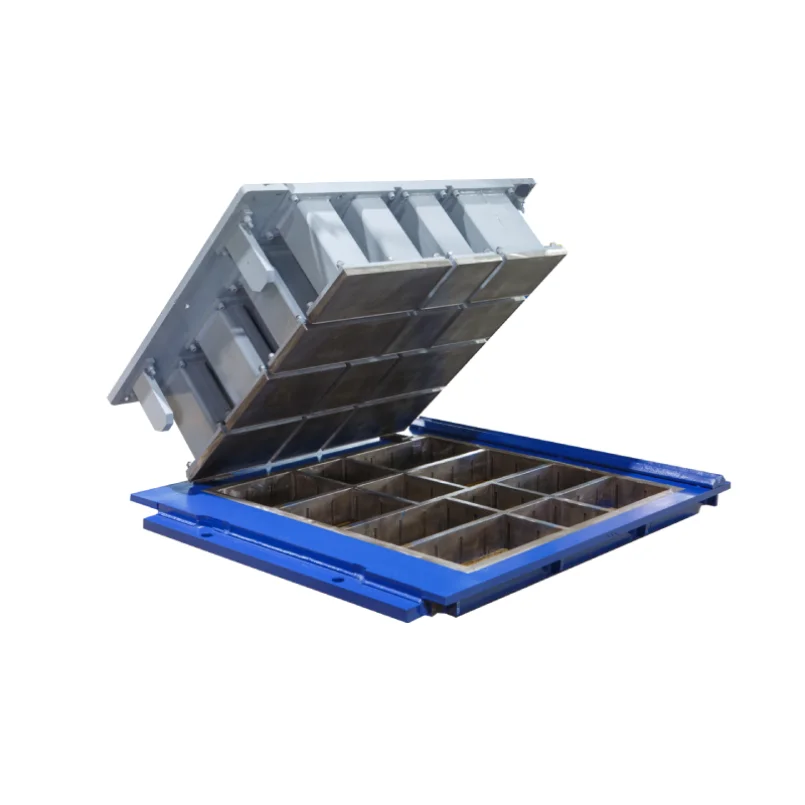

Optimizing production processes with advanced brick making technology has become a transformative force for manufacturers, especially those dealing with block molds for sale. These cutting-edge machines integrate automation, precision controls, and real-time monitoring, reducing manual intervention and human error. Whether producing moldes para bloques, road brick moulds, or custom brick types, these machines ensure consistent and high-quality output, with each brick exhibiting uniformity in size, shape, and strength. The integration of advanced sensors and AI-driven controls ensures that each stage of production—mixing raw materials, molding, and curing—is finely tuned for maximum efficiency.

One of the significant advantages of these technologies is their ability to reduce waste and optimize raw material usage. By using intelligent systems to control material input, manufacturers can minimize waste while ensuring that only the required amount of raw material is used. This not only cuts down on production costs but also makes the process more environmentally friendly. Furthermore, these machines are built to be energy-efficient, incorporating features like optimized motors and heating systems, which reduce operational costs and align with the growing demand for sustainable manufacturing practices in the construction industry.

The flexibility of modern brick making technology also allows manufacturers to adapt quickly to changing market demands. Machines can easily switch between different types of bricks, including block moulds and road brick moulds, without extensive reconfiguration or downtime. This adaptability ensures that manufacturers can produce a range of products while maintaining high-quality standards, responding to customer preferences, and staying ahead of market trends.

How Advanced Brick Making Technology Reduces Production Costs

Automation of Processes: Advanced brick making technology automates the majority of the production process, from mixing raw materials to molding, drying, and curing. This automation not only reduces the need for manual labor but also increases efficiency by minimizing human errors. Machines designed for block moulds for sale and road brick moulds can run continuously with minimal supervision, allowing businesses to boost production output without the added cost of an expanded workforce.

Eficiencia energética: Modern brick making machines, including those used for block moulds and road brick moulds, incorporate energy-efficient technologies such as optimized motors, intelligent heating systems, and real-time power management. These features reduce energy consumption during production, which lowers electricity costs. Many machines also include energy-saving modes that adjust power usage based on the specific needs of each production cycle, further enhancing cost efficiency.

Minimization of Material Waste: One of the key benefits of advanced brick making technology is its ability to precisely regulate the input of raw materials. Machines equipped with sensors and automated dosing systems ensure that only the necessary amount of clay, cement, or sand is used for each batch, reducing material waste. This precision not only improves the quality and consistency of block moulds and road brick moulds but also helps companies significantly lower material costs in large-scale operations.

Increased Production Speed: With high-speed production capabilities, modern brick making machines can produce more bricks in less time. Machines designed for block moulds and road brick moulds can operate continuously, reducing the time spent on each production cycle. This faster production speed means manufacturers can complete orders more quickly, cut down on operational costs, and meet tight deadlines more effectively, which enhances their competitiveness in the market.

Reduced Maintenance Costs: Advanced brick making machines are designed to be durable, with high-quality components that minimize wear and tear. Many machines come with self-diagnostic systems that can detect potential issues with critical parts used in producing block moulds and road brick moulds before they lead to significant breakdowns. This predictive maintenance reduces downtime and extends the life of the equipment, saving manufacturers on repair costs and minimizing production delays.

Quiénes somos

At KBL Machinery, we specialize in providing top-of-the-line brick making machinery, including solutions for block moulds for sale and road brick moulds. As a trusted proveedor de maquinaria de construcción, we offer high-performance, energy-efficient machines that enhance production processes, reduce costs, and support sustainable manufacturing practices. Our team of experts is dedicated to helping clients improve operational efficiency through innovative technology, ensuring they remain competitive in the ever-evolving construction industry. From initial consultation to after-sales support, we provide comprehensive services to meet the specific needs of our customers, building lasting partnerships for long-term success.