What Are the Benefits of Starting a Brick Manufacturing Business?

Dic 12, 2024

Bricks are essential in construction and will continue to be in demand due to their durability and versatility. As cities expand and construction projects multiply, the brick manufacturing industry presents substantial opportunities. Moreover, with growing awareness of sustainability, brick manufacturing has evolved, offering new business prospects for entrepreneurs.

High Market Demand

The need for bricks is undeniable across various sectors. Key factors contributing to this demand include:

- Strong growth: The global brick market is expected to grow to USD 309.6 billion by 2025, with a steady annual growth rate of 3.7%.

- Construction expansion: In key markets like the U.S. and India, over 10 million homes are being constructed annually, significantly increasing brick consumption.

- Paving bricks: The demand for specialized paving bricks is also growing, driven by urbanization and infrastructure development.

As the construction industry expands, manufacturers who can produce quality products like paving bricks y concrete blocks will benefit from this high demand.

Low Entry Barrier

One of the primary reasons entrepreneurs choose brick manufacturing is the relatively low initial investment. Here’s why:

- Affordable raw materials: Basic materials such as clay and fly ash are readily available and cost-efficient, generally priced between USD 40 and USD 60 per ton.

- Cost-effective machinery: Equipment like moldes para adoquines y concrete block molds can be purchased at a reasonable cost, with prices ranging from USD 6,000 to USD 12,000 for small-scale operations.

- Affordable labor: Labor costs remain competitive in most regions, allowing for cost-effective staffing.

With lower startup costs, brick manufacturing is accessible to many entrepreneurs. As businesses scale, these low costs allow them to increase production efficiently.

Sustainable Manufacturing Options

The demand for eco-friendly construction materials is growing, and brick manufacturers can meet this demand by offering sustainable products. Key trends include:

- Fly ash bricks: These bricks are gaining traction, as they consume 70-80% less energy to produce than traditional clay bricks and are more sustainable.

- Environmental impact: The growing construction industry has led to a push for greener solutions, positioning fly ash bricks as a viable alternative to traditional bricks.

- Sustainable growth: The global fly ash brick market is expected to grow at a CAGR of 5.6%, driven by eco-conscious buyers and regulatory pressures.

By incorporating sustainable practices, brick manufacturers can meet regulatory requirements and appeal to environmentally conscious customers, positioning themselves as industry leaders.

Low Operating Costs

Operating a brick manufacturing business involves relatively low ongoing costs. Consider these key factors:

- Material costs: Producing 1,000 bricks typically costs between USD 120 and USD 150, depending on the materials used.

- Energy efficiency: Modern production equipment, like concrete block molds, is designed to minimize energy consumption and reduce overheads.

- Labor costs: Skilled labor in the brick industry can be hired at a cost-effective rate, enabling businesses to maintain low operational costs.

With cost-efficient operations, brick manufacturers can maintain healthy profit margins while increasing production output.

Profitability and Growth Potential

Brick manufacturing can be highly profitable, with substantial growth potential. Some contributing factors include:

- High production volume: A large-scale operation can produce between 30,000 and 40,000 bricks per day, leading to significant revenues.

- Profit margins: Brick manufacturers typically see 40-50% profit margins, particularly with products like paving bricks.

- Consistent demand: With global construction demand growing, brick manufacturers are well-positioned to capture a significant share of the market.

Therefore, the increasing demand for quality bricks, particularly in urban development projects, ensures that brick manufacturing remains a viable and profitable business venture.

Flexibility and Customization

Brick manufacturing offers flexibility in product range and production methods. Here’s how:

- Variety of products: Manufacturers can produce multiple types of bricks, including paving bricks, to cater to different market segments.

- Personalización: Advanced molding technologies, like concrete block molds, allow manufacturers to customize brick shapes, sizes, and colors to meet specific customer needs.

- Escalabilidad: Businesses can start small and scale up production as demand increases, benefiting from economies of scale.

This flexibility makes it easy to adapt to changing market needs and expand production efficiently.

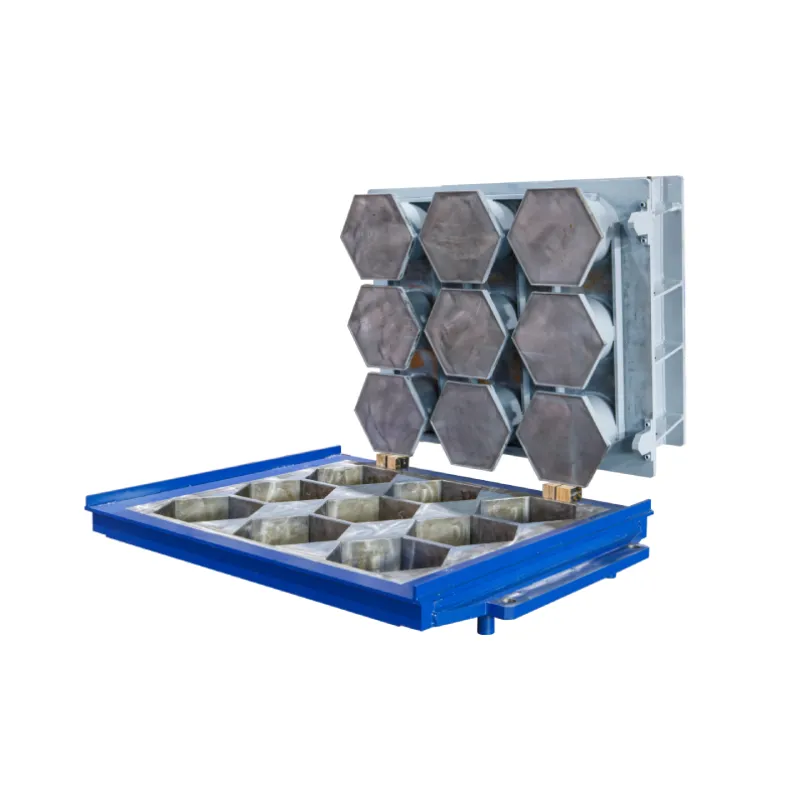

Paving Brick Moulds for Sale

When looking for paving brick moulds for sale, it’s essential to invest in high-quality molds that deliver durability and precision. KBL Machinery offers reliable and robust molds, providing several key advantages:

- Durabilidad: Our moldes para adoquines are built with high-quality steel, ensuring long-term performance even under heavy use.

- Precisión: These molds ensure uniform brick shapes, reducing waste and increasing production efficiency.

- Versatility: We offer various mold designs, allowing for different sizes and styles of paving bricks to suit your needs.

- Cost-effectiveness: KBL Machinery’s molds are designed to last longer, reducing the need for frequent replacements and enhancing your business’s profitability.

With KBL Machinery’s molds, your business can achieve excellent results in brick production, meeting the growing demand for high-quality paving bricks.

KBL Machinery: Your Trusted Partner in Brick Manufacturing

With nearly 30 years of experience, KBL Machinery is a leading provider of moldes para adoquines y concrete block molds. Our advanced machinery and molds help businesses produce top-quality bricks efficiently. We pride ourselves on providing the expertise and support necessary for success in the competitive brick manufacturing industry.

We look forward to building lasting partnerships with manufacturers worldwide, offering the tools and solutions you need to thrive in the brick production business.